Heat-resisting flame-retardant fiberglass product for industrial heat preservation and preparation method thereof

A flame-retardant, glass fiber technology, applied in the field of heat-resistant and flame-retardant industrial glass fiber products for thermal insulation, can solve the problems of poor heat-resistant and flame-retardant effect, widespread application, sticky product feel, etc., and achieve good flexibility , The effect of low raw material cost and mature coating process

Inactive Publication Date: 2010-06-16

NANJING UNIV OF INFORMATION SCI & TECH

View PDF0 Cites 23 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In the prior art, silicone resin can be used as the glass fiber binder. Silicone resin has good heat resistance, flame retardancy and flexibility, good hand feeling and bright white color, but the price is expensive, which limits its use. range, it cannot be widely applied in the industry; at present, there is an industrial thermal in

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a heat-resisting flame-retardant fiberglass product for industrial heat preservation and a preparation method thereof. The preparation method of the fiberglass product comprises the following steps of: firstly evenly mixing all components in percentage by mass according to a gelatine prescription to prepare a glue solution, forming a coating on fiberglass cloth by adopting the glue solution in a coating or soaking cementing way, and finally drying and curing to obtain the fiberglass product; wherein the coating amount of the coating on the surface of the fiberglass cloth is 20 to 220g/m<2>, and the coating weight is 10 to 40 percent of the fiberglass product; and the gelatine is prepared by mixing all components. The finished product obtained after drying and sizing is used for heat insulation, flame retarding and heat preservation outside the wall of an industrial pipeline or a vessel, and is especially suitable for occasions which have higher requirements for heat preservation and flame retarding.

Description

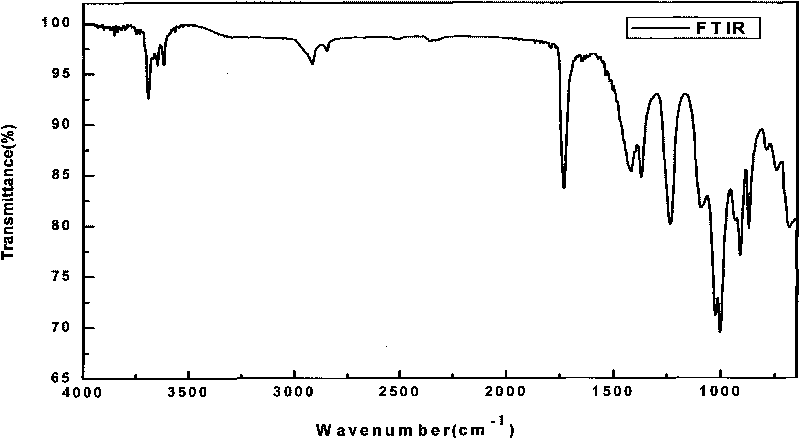

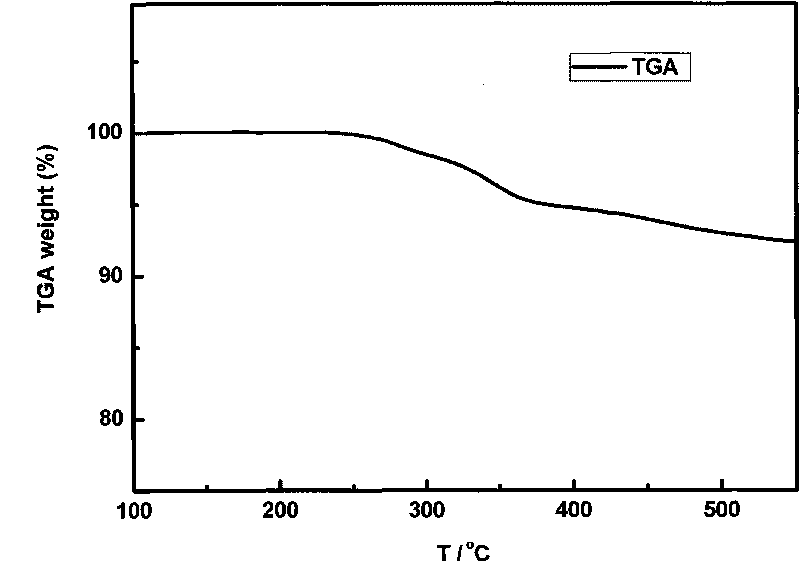

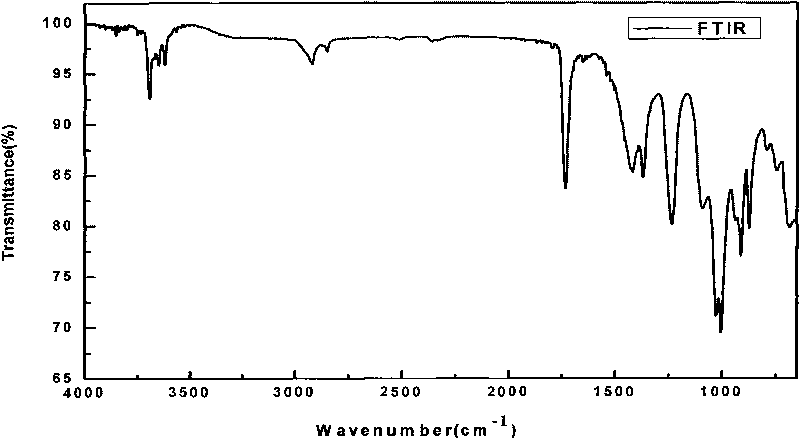

1. Technical field: [0001] The invention relates to a heat-resistant and flame-retardant glass fiber product for industrial heat preservation, which is mainly used in industry, construction, decoration, electrical appliances and other related heat preservation and energy-saving fields, and is especially suitable for industrial heat preservation fields that require high heat resistance and flame retardancy. Such as industrial devices and pipelines that need heat preservation. 2. Background technology: [0002] At present, glass fiber insulation products have been widely used in the fields of construction, decoration, electrical appliances and industrial production, but most of them have low heat-resistant and flame-retardant grades, and it is difficult to meet the needs of industrial insulation fields with high operating temperature and high flame-retardant grade requirements. Heat-resistant and flame-retardant glass fiber products have become a hot topic, and the key to flam...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): D06M15/333D06M15/227D06M11/47D06M11/79D06M11/76D06M13/165D06M13/156D06M13/08B29C70/50D06M101/16

Inventor 郭彦何辉徐建强

Owner NANJING UNIV OF INFORMATION SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com