Method for measuring effective propagation distance of ultrosonic in metal melt and its special device

A technology of propagation distance and metal melt, which is used in the analysis of solids using sonic/ultrasonic/infrasonic waves, and can solve problems such as the inability to determine the effective propagation distance of ultrasonic waves, corrosion effects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

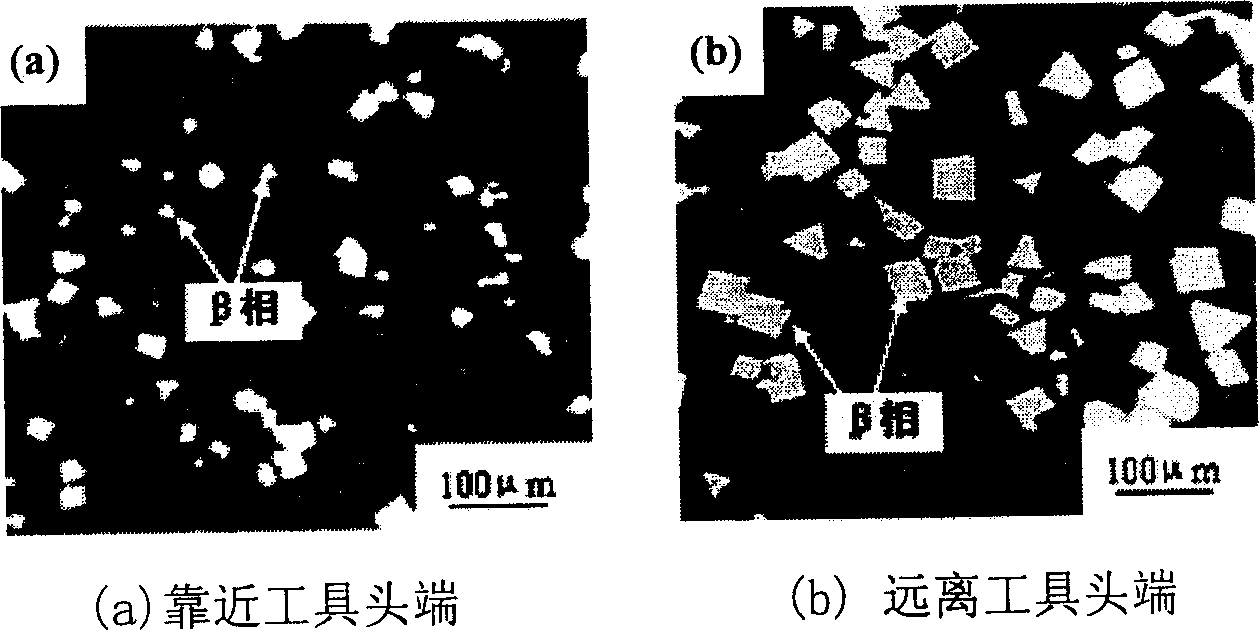

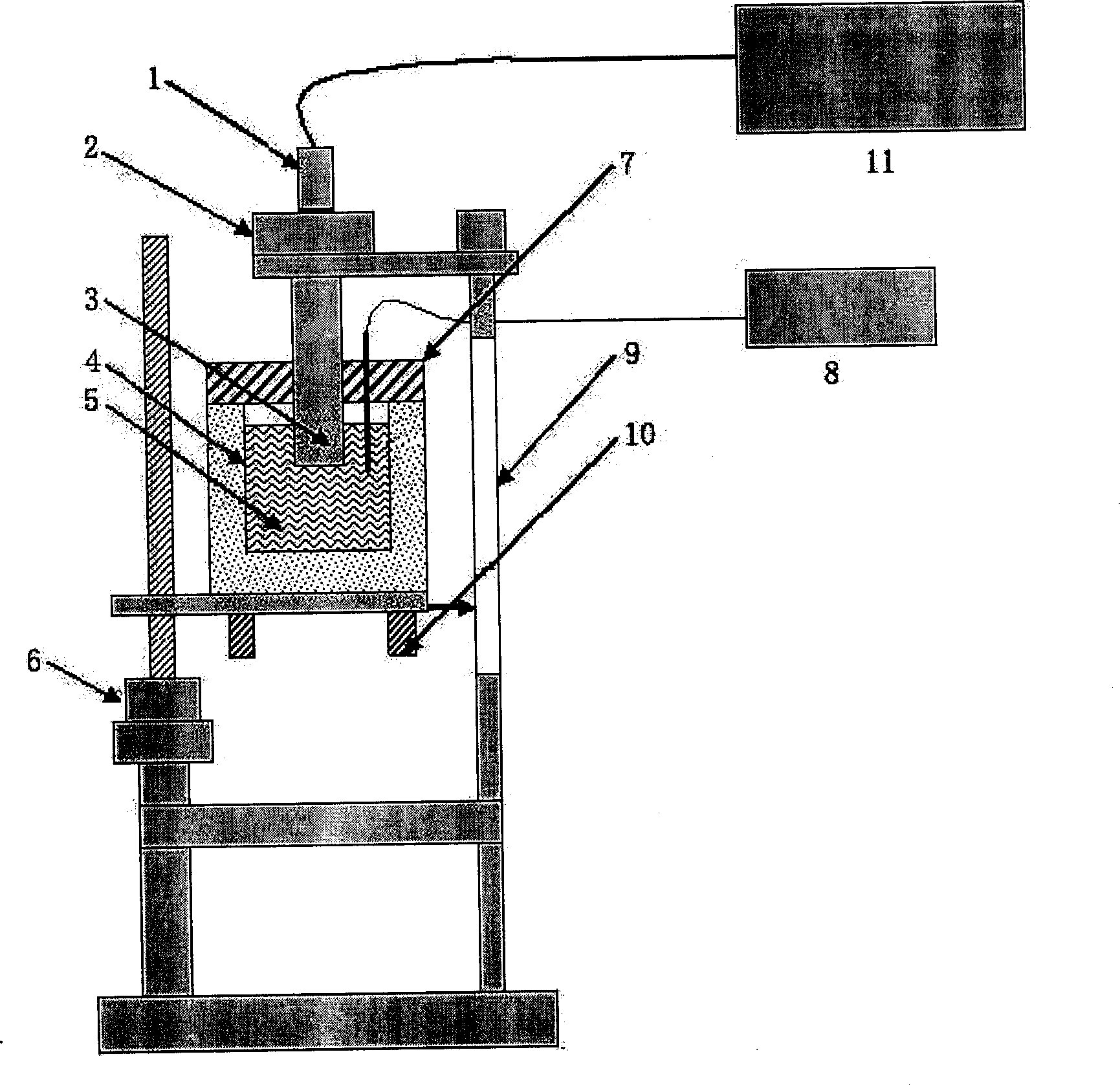

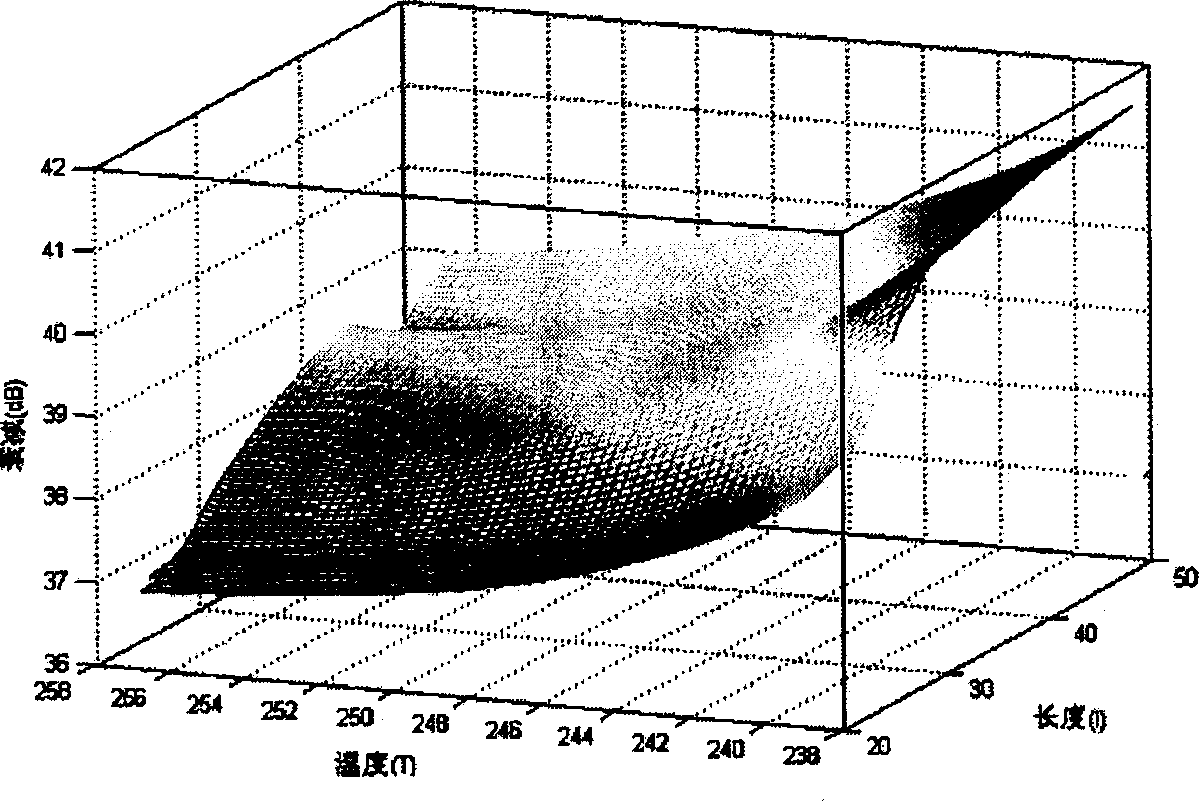

Embodiment 1

[0021] Put an appropriate amount of Sn-10% Sb binary alloy into the crucible 4, the upper bottom surface of the crucible is a corrosion-resistant metal surface with a surface roughness less than 0.8 μm, cover the heat preservation cover 7, and heat the metal until the temperature exceeds the liquid temperature of the alloy. When the phase line is 257°C, stop heating. Adjust the lifting handle 6, slowly move the guide rod 3 into the liquid metal melt, and turn the leveling nut 10 to make the upper bottom surface of the crucible perpendicular to the guide rod. The distance between the bottom end of the guide rod and the upper bottom surface of the crucible is adjusted to 20mm by the lifting handle 6 and the scale 9. The water cooling device 2 is turned on, the ultrasonic transmitting and receiving device 11 is turned on, and the ultrasonic wave is indirectly introduced into the liquid metal through the ultrasonic probe 1 . As the metal melt cools in crucible 4 , the temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com