Lubricating device of precisely-stamped die

A technology for lubricating devices and molds, applied in forming tools, manufacturing tools, presses, etc., can solve the problems of insufficient lubricant introduction, dry friction, etc., and achieve the effect of improving the lubrication effect and prolonging the life of the mold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

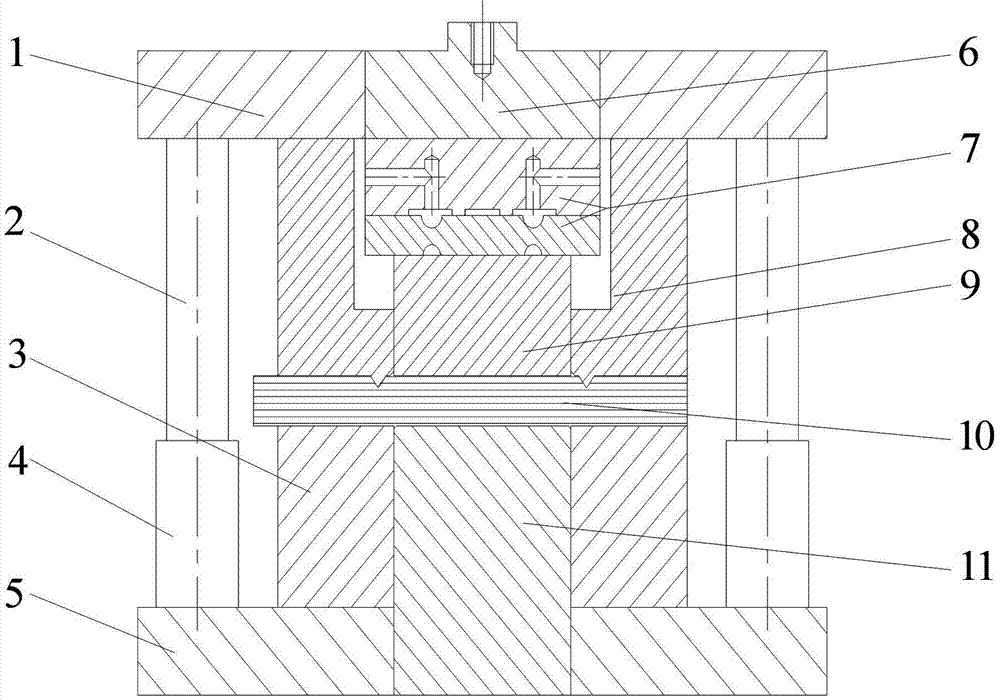

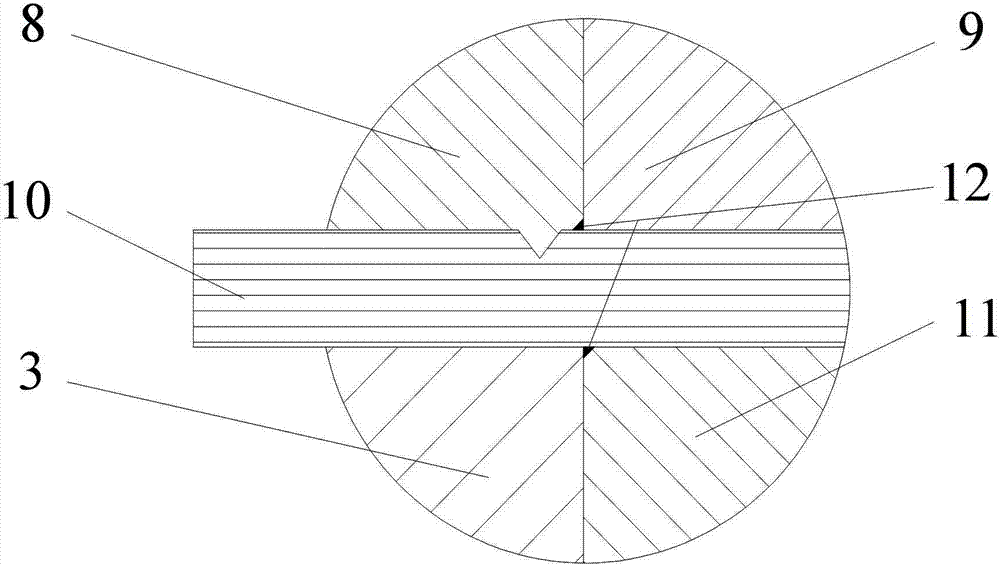

[0014] figure 1 The general assembly diagram of a typical fine blanking die is shown. The fine blanking die includes an upper template 1, a lower template 5, a punch 9, a reverse ejector rod 11, a guide column 2 connecting the upper template 1 and a lower template 5, and a guide sleeve 4 ; The mold base is provided with an upper template 1 and a lower template 5 for relative movement, and the lower end of the guide post 2 is located in the guide sleeve 4; the V-shaped blank holder 8 is fixed on the upper template 1; the electro-hydraulic vibration starting device 7 It is fixed on the pressure pad 6; the punch 9 is fixed on the electro-hydraulic vibration starting device 7; the die 3 is fixed on the lower template; the reverse ejector rod 11 is connected with the hydraulic plunger on the fine blanking machine.

[0015] A lubricating device for a fine blanking die, which comprises a pressure backing plate 6 of the fine blanking die, a punch 9, a V-shaped blank holder 8, and an a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com