A vertical hydraulic plunger mud pump

A hydraulic column and mud pump technology, applied in the field of vertical hydraulic plunger mud pumps, can solve the problems of low mechanical efficiency, unusable long-distance slurry transportation, high frequency of operation, etc., achieve volume and quality reduction, easy overload protection, The effect of large carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

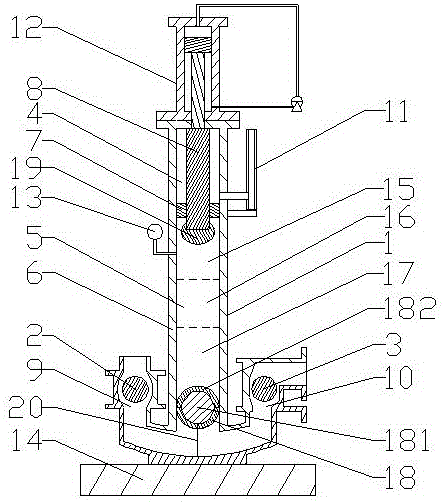

[0024] Accompanying drawing is the specific embodiment of the present invention. Such as figure 1 As shown, this kind of vertical hydraulic plunger mud pump includes a vertical plunger type mortar cylinder 1, which is installed on the base 14. The plunger type mortar cylinder 1 includes a cylinder body 6, a piston rod 8 and a replaceable annular The support seal ring 7, the piston rod 8 is a chrome-plated piston rod, and its lower end is equipped with a wear-resistant cap 19 made of ultra-high molecular weight polyethylene material. The annular support seal ring 7 is detachably fixed on the cylinder body 6 and sleeved on the piston. On the column 8, the annular support sealing ring 7 divides the inner cavity of the cylinder body 6 into an upper cavity 4 and a lower cavity 5, and a transparent open heat dissipation position indicator 11 is provided on the side wall of the upper cavity 4, and an open radiator It communicates with the upper cavity 4; the mud in the lower cavity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com