Gap seal hydraulic cylinder based on deformable piston ring

A technology for sealing hydraulic pressure and piston rings, applied in the field of hydraulic cylinders, can solve the problems of low volume efficiency of hydraulic cylinders, high cost of replacing pistons, affecting the life of seals, etc., to achieve the effects of improving efficiency, reducing maintenance costs and preventing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

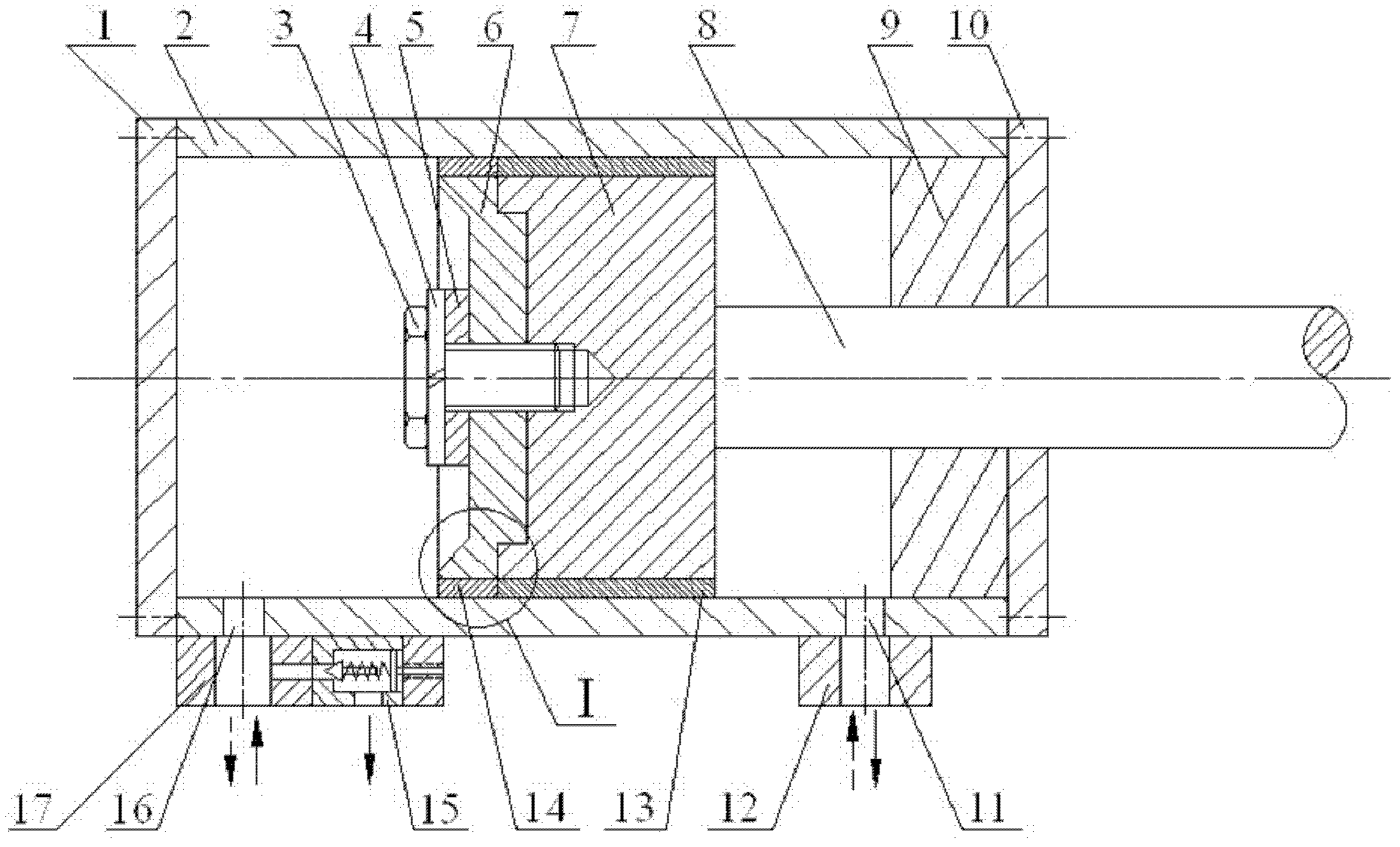

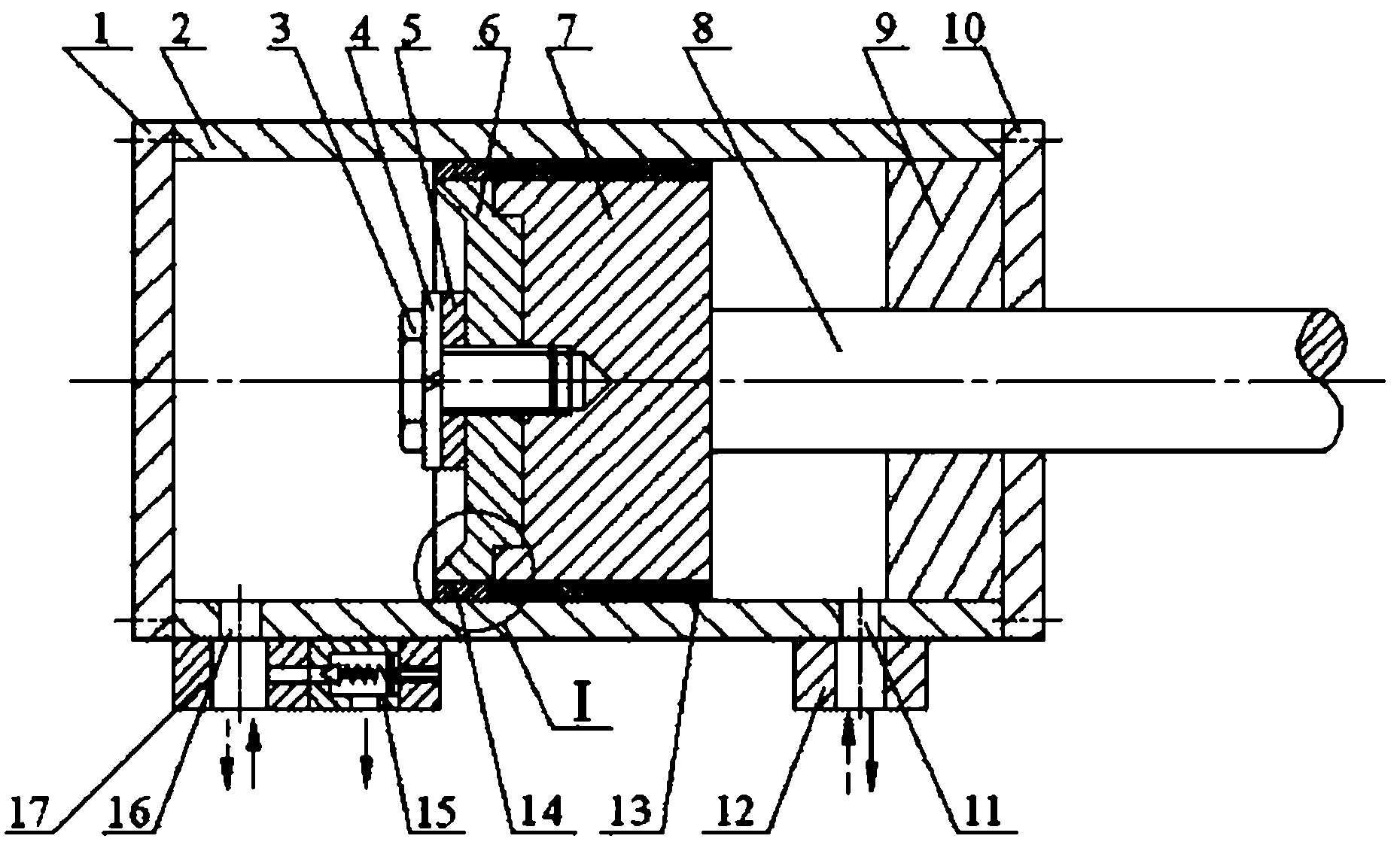

[0019] A gap-sealed hydraulic cylinder based on deformed piston rings. The hydraulic cylinder is figure 1 As shown, the right end surface of the deformed piston ring 6 is composed of a concentric cylindrical boss and an annular bottom surface, the left end surface of the piston 7 is composed of a concentric concave round bottom and an annular boss, and the ring on the left end surface of the piston 7 Shaped boss cross-section is rectangular, and the cylindrical boss outer diameter and height of the right end surface of deformed piston ring 6 are identical with the concave round bottom inner diameter and depth of the left end surface of piston 7 respectively; The cylindrical boss end surface of deformed piston ring 6 Concentrically close to the concave round bottom of the piston 7 and the end surface of the annular boss with the annular bottom surface. The external diameter of deformed piston ring 6 is identical with the external diameter of piston 7, and the center of deforme...

Embodiment 2

[0024] A gap-sealed hydraulic cylinder based on deformed piston rings.

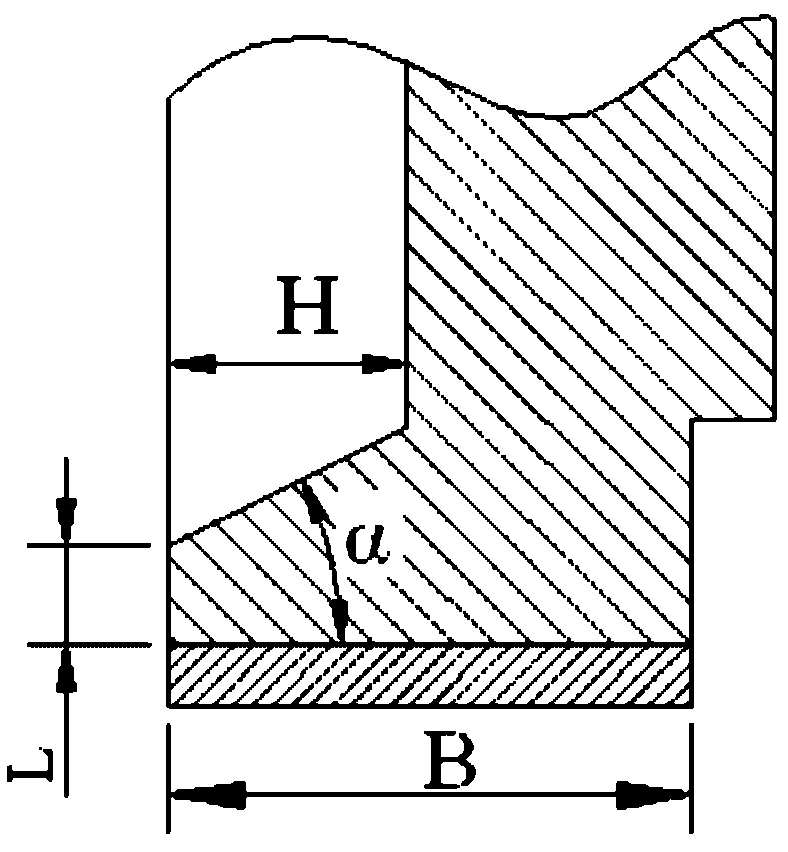

[0025] The height H of the right-angled trapezoid=10~12mm, the length L=1.0~1.2mm of the upper bottom, the included angle α=30~40° between the hypotenuse and the right-angled side of the right-angled trapezoid; the thickness B of the cylindrical surface of the deformed piston ring 6=20~ 25 mm; the layer thicknesses of the first aluminum bronze layer 14 and the second aluminum bronze layer 13 are both 0.8-1.0 mm.

[0026] All the other are with embodiment 1.

Embodiment 3

[0028] A gap-sealed hydraulic cylinder based on deformed piston rings.

[0029] The height H of the right-angled trapezoid=9~11mm, the length of the upper bottom L=0.9~1.1mm, the included angle α=25~35° between the hypotenuse and the right-angled side of the right-angled trapezoid; the thickness B of the cylindrical surface of the deformed piston ring 6=18~ 22 mm; the layer thicknesses of the first aluminum bronze layer 14 and the second aluminum bronze layer 13 are both 0.6-0.8 mm.

[0030] All the other are with embodiment 1.

[0031] Compared with the prior art, this specific embodiment has the following positive effects:

[0032] (1) In this specific embodiment, a concave-convex deformed piston ring 6 is installed on the left end of the piston 7. The cylindrical convex table surface of the deformed piston ring 6 is embedded with the concave round bottom of the piston 7, and the two are concentrically connected by the screw 3. The latter is fastened, and the cylindrical s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com