Water spraying and oil spraying device of flax wet-spinning spinning machine

A technology of wet spinning spinning frame and oil injection device, which is applied in the direction of mechanical equipment, engine components, textiles and paper making, etc. It can solve the problems of excessive spinning channel mud, quality impact, steel ring not available, etc., to achieve cleaning and lubricating thoroughly, saving water and oil consumption, automatic cleaning and lubricating effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

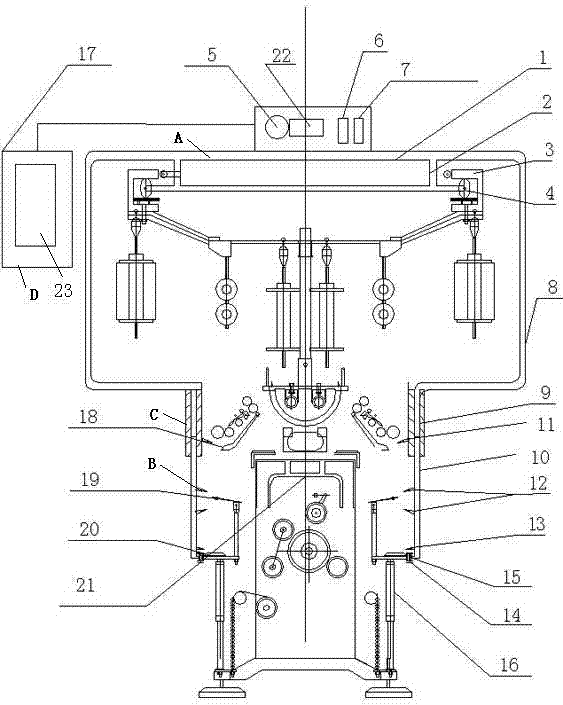

[0011] see figure 1 , The present invention includes a walking part A, a water spraying oil spraying part B, a steel plate lifting follower part C and a control part D. The walking part A includes a motor 22 , a gear box 5 , an upper guide rail 3 , an upper pulley 4 , a traveling trolley 1 , a traveling trolley frame 2 and a driving arm 8 . Water injection and fuel injection parts B include water injection solenoid valve 6, oil injection solenoid valve 7, oil pump (not shown in the figure), pipeline (not shown in the figure), first group of water spray nozzles 11, second group of water spray nozzles 12 And fuel injection nozzle 13. The steel plate lifting follower part C comprises a slide bar 10, a chute 9, a lower guide rail 14 and a lower pulley 15. The control part D includes a touch screen 23 and a PLC 17 . The present invention also relates to the elevating cylinder 16, the probe rod 18, the yarn guide 19, the steel ring 20, and the main frame 21 of the flax wet spinni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com