Crawling ladder welding device based on ground rail robot

A welding device and robot technology, used in auxiliary devices, welding equipment, engine lubrication, etc., can solve problems such as lubricating oil easily contaminated with dust, increasing cleaning difficulty, bending deformation at both ends of L-shaped crossbar, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

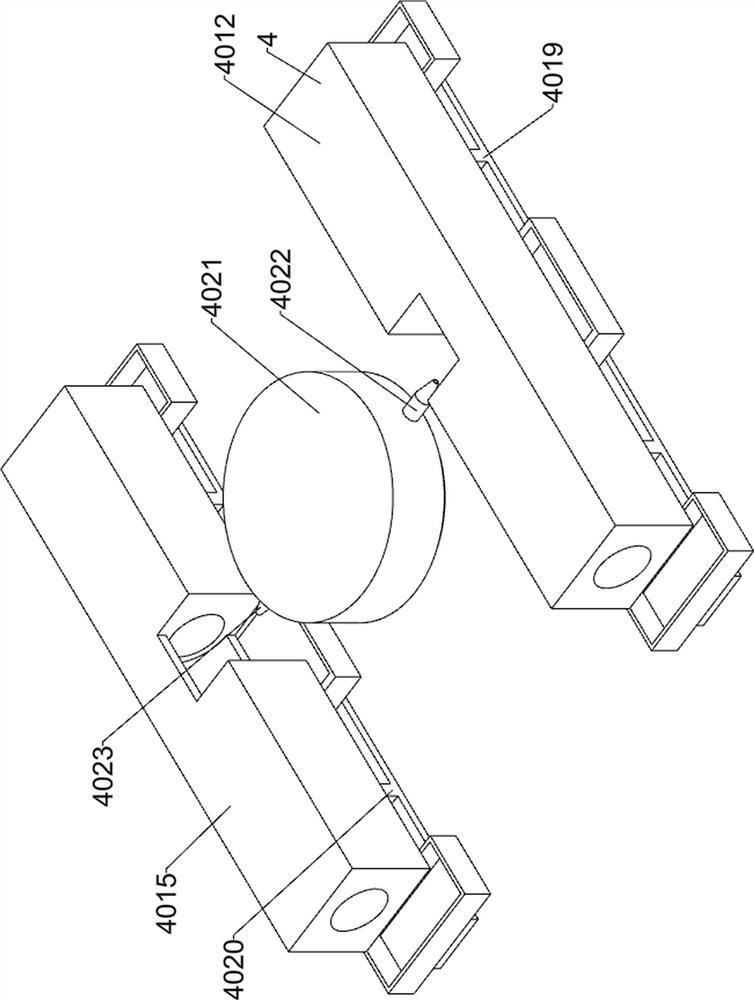

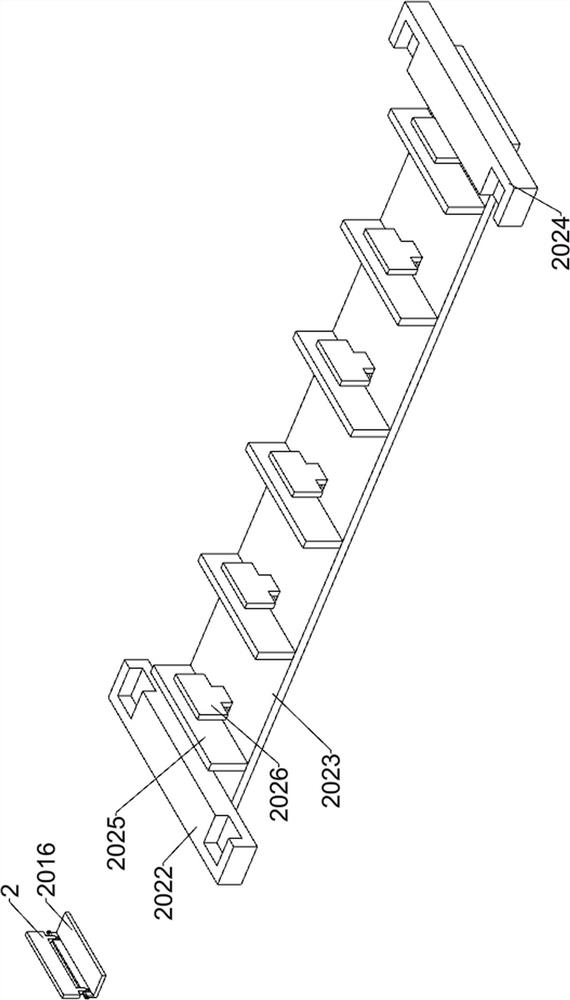

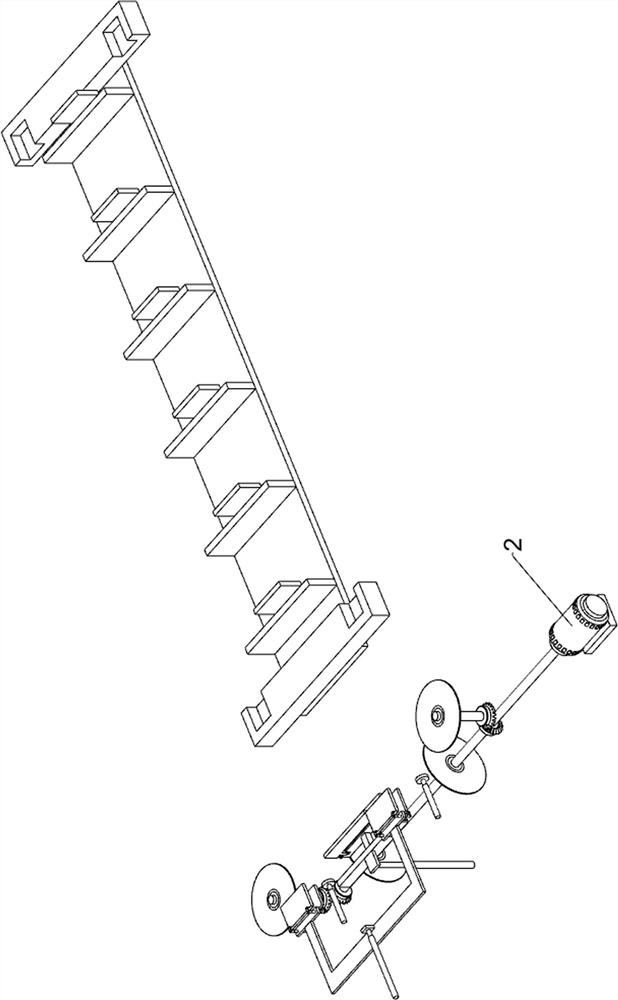

[0031] A ladder welding device based on a ground rail robot, such as Figure 1-11 As shown, it includes an underframe 1, a pendulum assembly 2, a transport assembly 3, a welding assembly 4, a base 5, a control panel 6, a first support block 7, a first anti-skid block 8, a first storage box 9 and a first limit The bit block 10; the bottom frame 1 is connected with the pendulum assembly 2; the bottom frame 1 is connected with the transport assembly 3; the bottom frame 1 is connected with the welding assembly 4; The screen 6 is fixedly connected; the base frame 1 is fixedly connected with the four sets of first support blocks 7; the base frame 1 is fixedly connected with the first storage box 9; the pendulum assembly 2 is connected with the welding assembly 4; 6 for fixed connection; four sets of first support blocks 7 are respectively fixedly connected with four groups of first anti-skid blocks 8;

[0032] Working principle: When preparing for work, place the device on a horizo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com