High speed gear spead increaser having automatic lubricating system

A high-speed gear, automatic lubrication technology, applied in the direction of belt/chain/gear, gear transmission, gear lubrication/cooling, etc., can solve the problem of reducing the service life of the speed-up gearbox, reducing cleanliness, high-speed gear speed-up structure and Use complication and other issues to achieve the effect of realizing circulation and simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

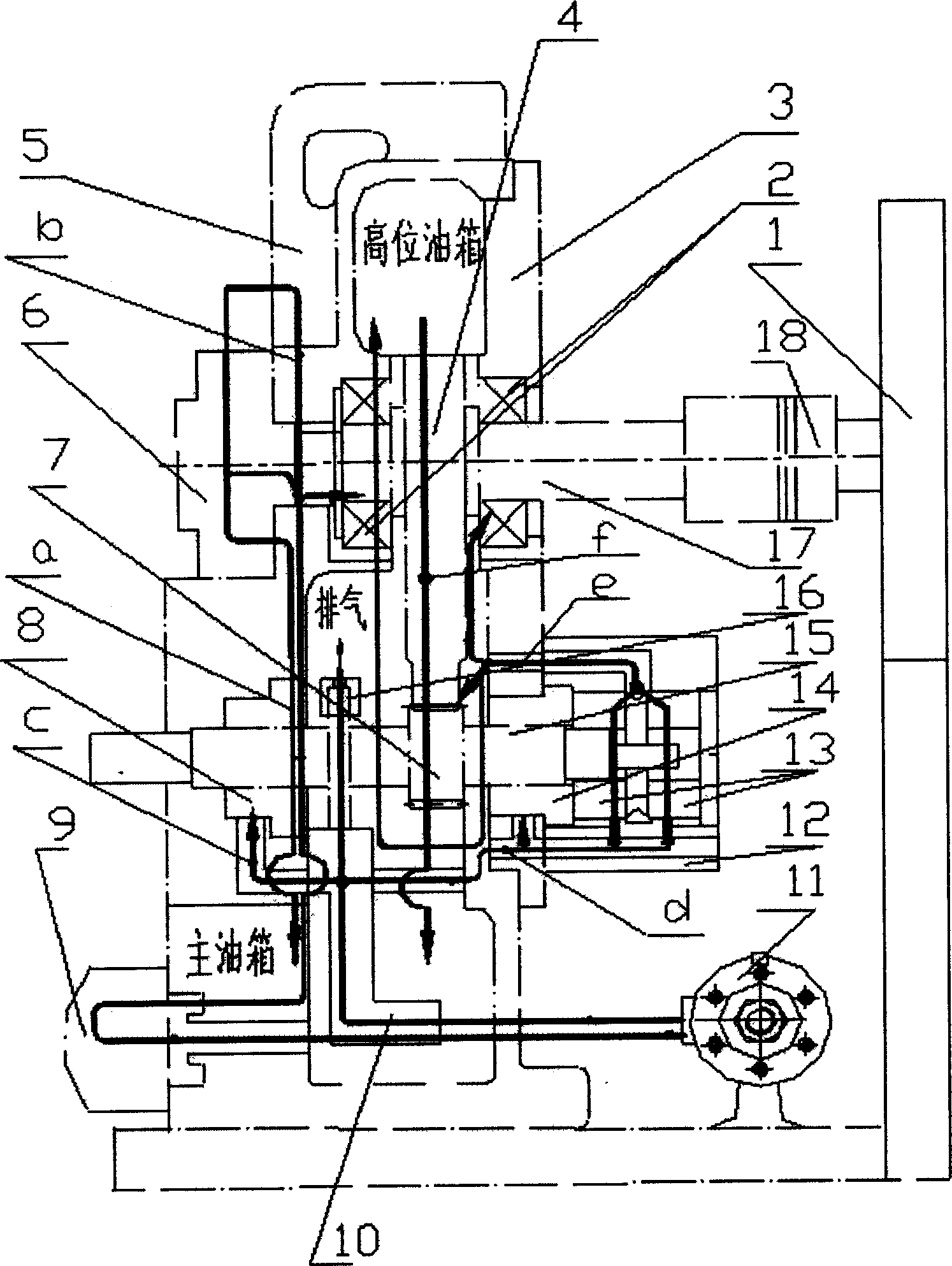

[0010] Embodiment of the present invention: select the oil pump 6 matched with the motor 1, and make each component. as per figure 1 Assemble as shown;

[0011] First, install the low-speed gear 4 and two ball bearings 2 on the low-speed shaft 16. The two ball bearings 2 are respectively installed on the left and right sides of the low-speed gear 4. The ball bearings 2 are supported on the box body 5, and then the oil pump 6 is installed. At the left end of the low-speed shaft 16; the high-speed gear 7 is installed on the high-speed shaft 15, the front radial bearing 8 is installed on the left side of the high-speed gear 7, and each bearing is supported on the box body 5, so that the low-speed gear 4 and the high-speed gear 7 meshing;

[0012] Secondly, the rear radial bearing 14 is installed on the case cover 3; two thrust bearings 13 are installed in the corresponding positions of the bearing housing (12); the bearing housing 12, the case cover 3 and the casing 5 are conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com