Agricultural machine transmission gear

A technology for transmission gears and agricultural machinery, which is applied to transmission parts, gear lubrication/cooling, belts/chains/gears, etc., and can solve the problems of being easily entangled by soil, rocks or weeds, hindering, and burning the driving device.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

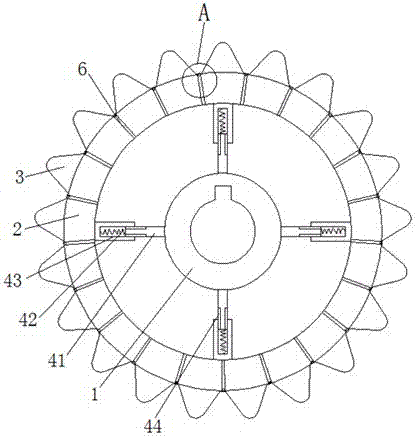

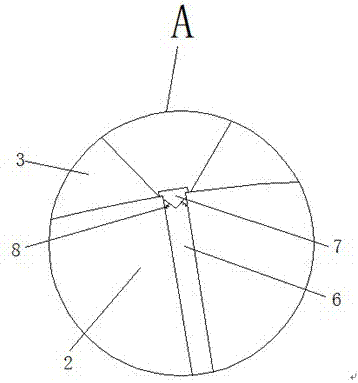

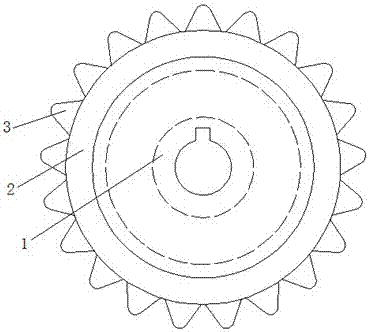

[0019] Embodiment: The device is fixed on the transmission shaft through the fixing hole and the keyway. During the rotation, if sand or small impurities enter the transmission gear, the first fixed ring 1 is driven by the telescopic column 4 to connect with the second fixed ring. 2 A slight displacement occurs, the elastic sleeves on both sides of the extrusion part are squeezed, and the elastic sleeves on the upper and lower sides of the extrusion part slide in the chute, which will squeeze the lubricating oil chamber, and the lubricating oil will squeeze the sealing plug 7, driving The second spring 8 expands and contracts, and the lubricating oil in the lubricating oil chamber is sprayed out from the oil guide hole 6 to clean and lubricate the stuck part of the gear. If the entire transmission gear is blocked, the transmission shaft will drive the first fixed Ring 1 produces positive torque, and second fixed ring 2 produces reverse torque, which will cause the telescopic co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com