Automatic lubricating device for steel wire rope for swabbing truck

An automatic lubrication and steel wire rope technology, which is applied in the direction of engine lubrication, hoisting device, engine components, etc., can solve the problems of lubrication fracture, poor lubrication effect and low lubrication efficiency of the wire rope of the swabbing car, and avoid the influence of running actions , improve timeliness and stability, and ensure the effect of sufficient lubrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

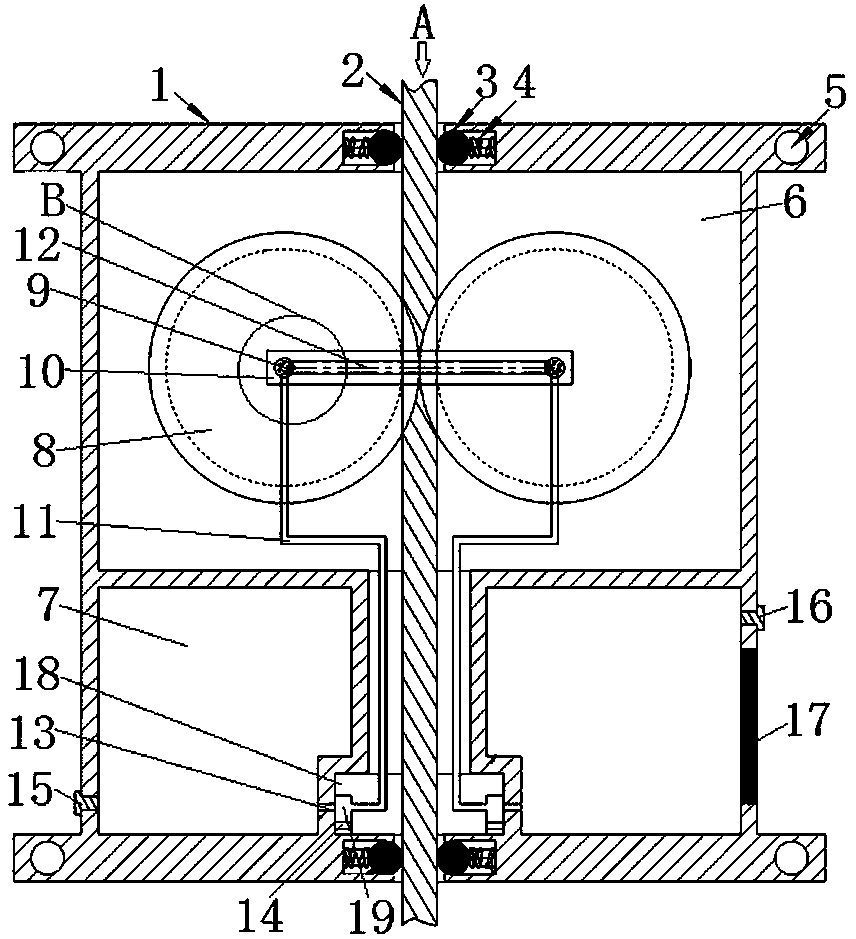

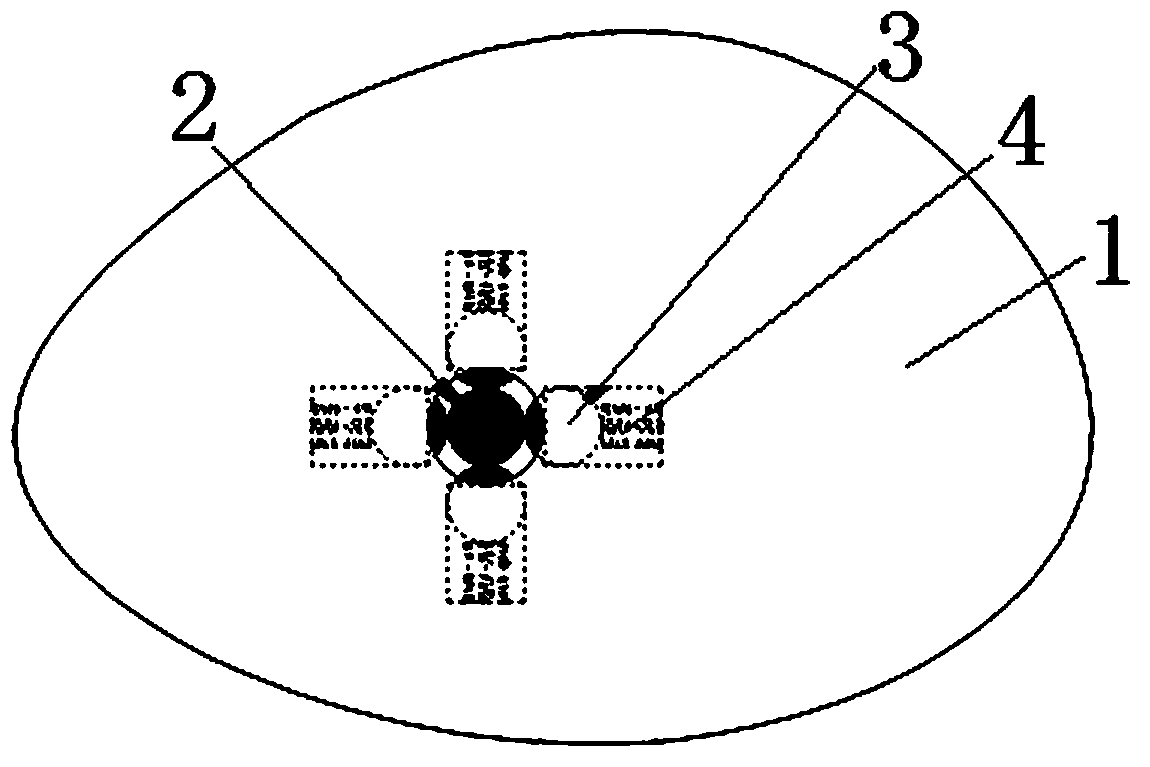

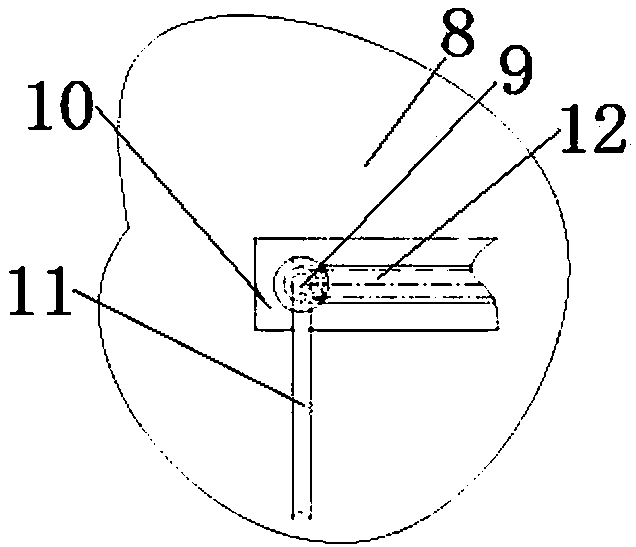

[0028] see figure 1 , figure 2 and image 3 As shown, the present invention includes a housing 1 and an oil chamber 7 arranged in the housing 1 , a trigger mechanism and a conversion link 11 .

[0029] Wherein, the housing 1 is a hollow shell structure with a square outline. The four corners of the housing 1 are respectively provided with four fixing holes 5, and the four fixing holes 5 are distributed on the housing 1 in a symmetrical manner (either left-right symmetry or up-down symmetry) at the four corners of the housing 1, The casing 1 is installed on the pumping cart through the fixing hole 5, and the installation position of the casing 1 on the pumping cart is on the running track of the steel wire rope 2 of the pumping cart in the up and down direction. In this way, it is required to form a passing passage for the steel wire rope 2 in the up and down direction of the housing 1, and ensure that the steel wire rope 2 can travel longitudinally between the inner cavity...

Embodiment 2

[0039] The invention includes a housing, an oil cavity arranged in the housing, a trigger mechanism and a conversion connecting rod.

[0040] Wherein, the shell is a hollow shell structure with a square outline structure. The four corners of the housing are respectively provided with four fixing holes, which are symmetrically distributed on the housing at the four corners of the housing (both left and right symmetry, and up and down symmetry), and the housing passes through the fixing holes Installed on the pumping car, the installation position of the housing on the pumping car is on the running track of the steel wire rope of the pumping car in the up and down direction. In this way, it is required to form a passing channel for the steel wire rope in the up and down direction of the housing, and through the passing channel, it is ensured that the steel wire rope can travel longitudinally between the inner chambers of the housing during operation; based on the longitudinal ru...

Embodiment 3

[0049] Other contents of this embodiment are the same as those of Embodiment 1 or 3, except that the overall outline of the housing is a cylindrical structure, and the fixing holes on the housing are formed in other structural forms that facilitate fixing on the swabbing cart.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com