Self-lubricating vibration isolation type bench drill for vehicle remanufacturing

A remanufacturing and self-lubricating technology, which is applied in the field of self-lubricating vibration-isolation bench drills for automobile remanufacturing, can solve the problems of manual lubrication and poor vibration-isolation effect of bench drills, and achieve good vibration-isolation and vibration-isolation effects Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

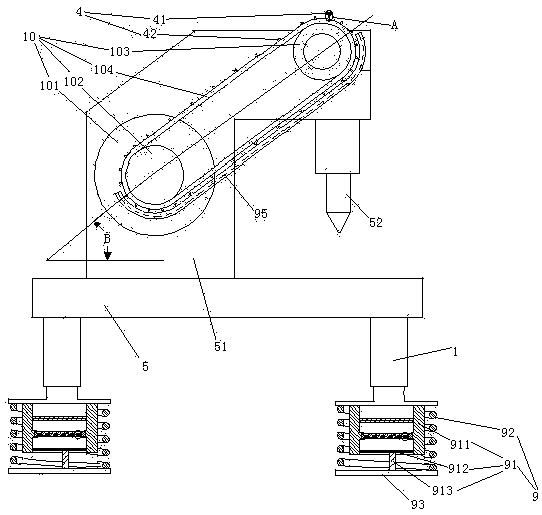

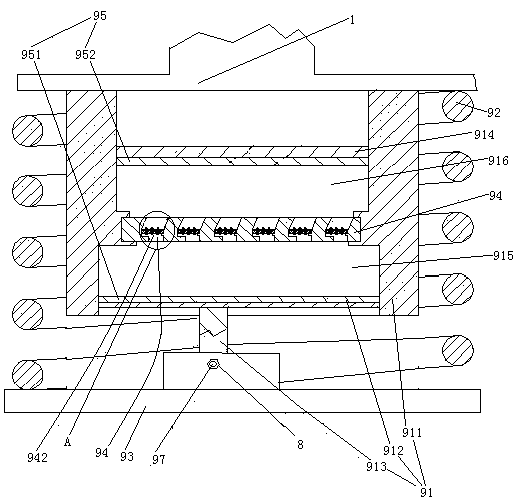

[0031] see figure 1 What is claimed is a self-lubricating vibration-isolation bench drill for automobile remanufacturing, comprising a support foot 1 . The upper end of the supporting foot 1 is provided with a platform 5 .

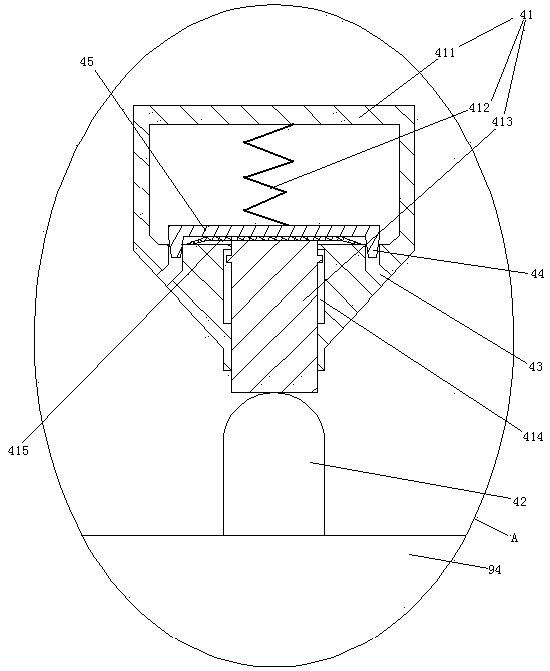

[0032] The table top 5 is provided with a stand 51 . The stand 51 is provided with a lubricating device 4, a drill bit 52 with the head facing down and a drive mechanism 10 for driving the drill bit to rotate.

[0033] The driving mechanism 10 includes a motor 101 , a driving sprocket 102 , a driven sprocket 103 and a chain 104 . The motor 101 is fixed to the stand 51 . The driving sprocket 102 is connected on the power output shaft of the motor 101 . The driven sprocket 103 is connected with the rotating head 52 through a transmission mechanism. The driven sprocket 103 is located obliquely above the driving sprocket 102 . Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com