Stop valve

A shut-off valve and valve stem technology, which is applied in the field of valve manufacturing, can solve the problems of easy damage of the valve stem, long closing time, and shut-off valve opening, so as to avoid strain or damage, quickly separate, and improve the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

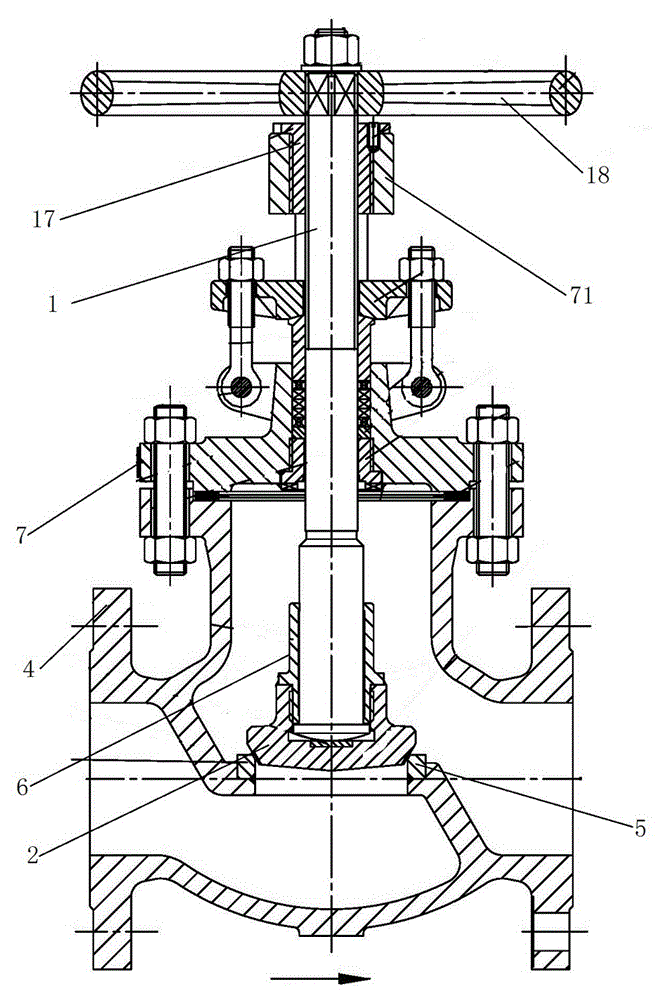

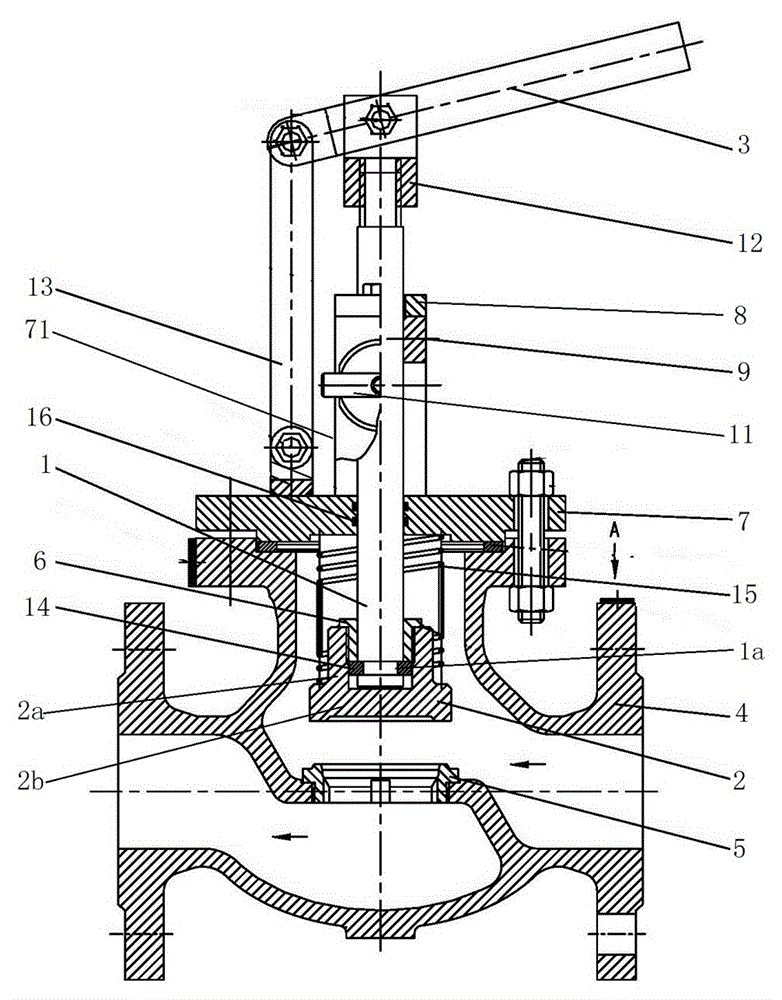

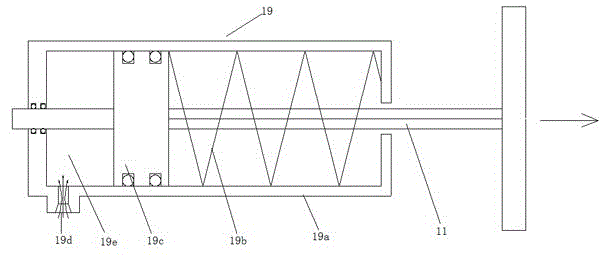

[0037] Such as figure 2 As shown, this embodiment provides a shut-off valve, including a valve body 4 with a top opening, a valve cover 7 sealingly connected to the top opening, and a valve stem extending into the inside of the valve body 4 through the valve cover 7 for sealing. 1. The valve disc 2 connected to the bottom of the valve stem 1 and located inside the valve body 4, and the valve seat 5 with an opening arranged inside the valve body 4, the valve stem 1 can go up and down under the action of the control mechanism The movement drives the valve disc 2 to open or close the opening on the valve seat 5, the control mechanism includes a support rod 13 arranged on the valve cover 7, an operating rod 3 movably connected to the support rod 13, the The operating rod 3 is movably connected with the top of the valve rod 1, and the operating rod 3 can swing under the action of an external force to drive the valve rod 1 to move up and down, and also includes a driving mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com