Lamination manufacturing method for imbedded inductance magnet ring

A manufacturing method and magnetic ring technology, applied in the field of electronics, can solve the problems of filling the cavity of embedded inductive magnetic ring products, quality cannot be guaranteed, high cost, etc., and achieve the effect of increased bonding strength, reliability assurance, and quality assurance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing, the present invention is described in further detail with embodiment:

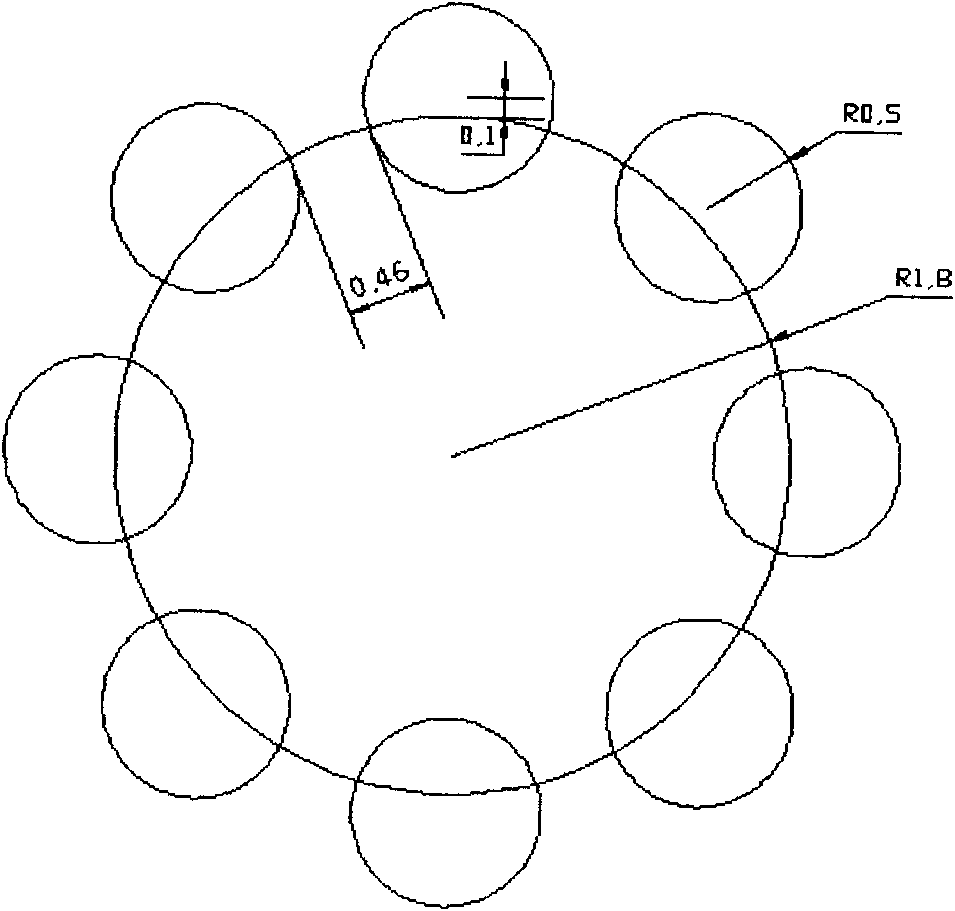

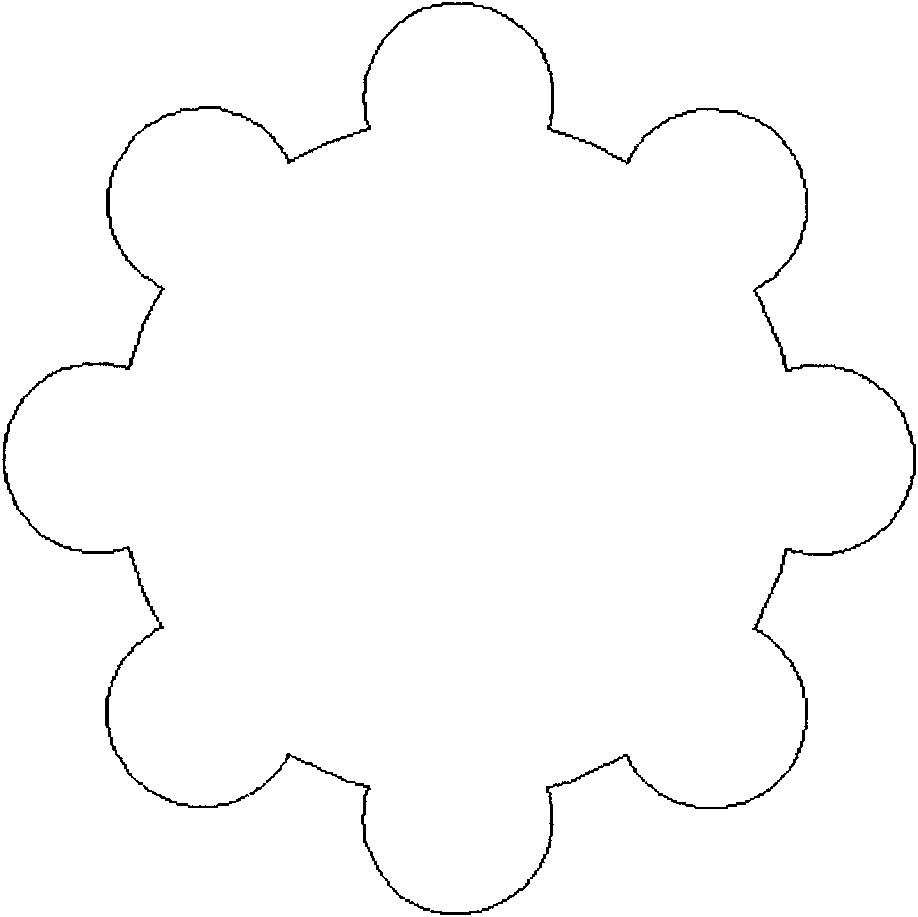

[0025] Taking the inductance magnetic ring as a circle: the outer diameter is 3.55mm, the inner diameter is 1.75mm, and the thickness is 1.55-1.6mm as an example to illustrate the specific implementation:

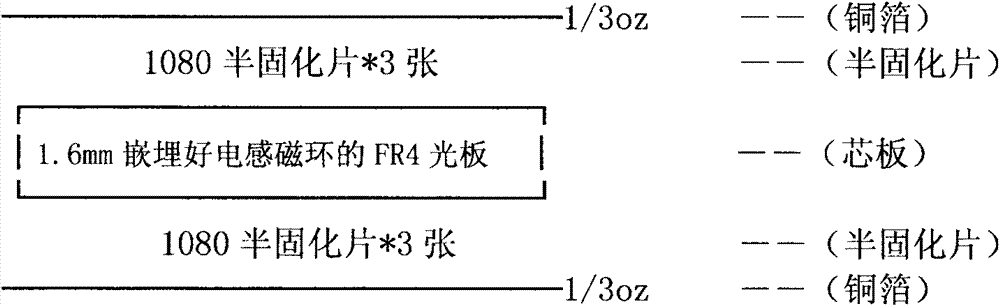

[0026] A: The first is the design guarantee: according to the size and thickness requirements of the inductance magnetic ring, the design determines the material selection standard of the substrate thickness and the aperture size. Then according to different plate thickness requirements, by calculating the size and quantity of the aperture, the theoretical filling amount of the filling hole during pressing is calculated, and then the quantity of 1080 semi-solid sheet used in pressing is determined.

[0027] The specific design principles are as follows:

[0028] The basic design process is:

[0029] Ⅰ: Use 1.6mm common FR4 copper clad laminate, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com