Method for producing amorphous alloy jewelry and its pipe sprayer

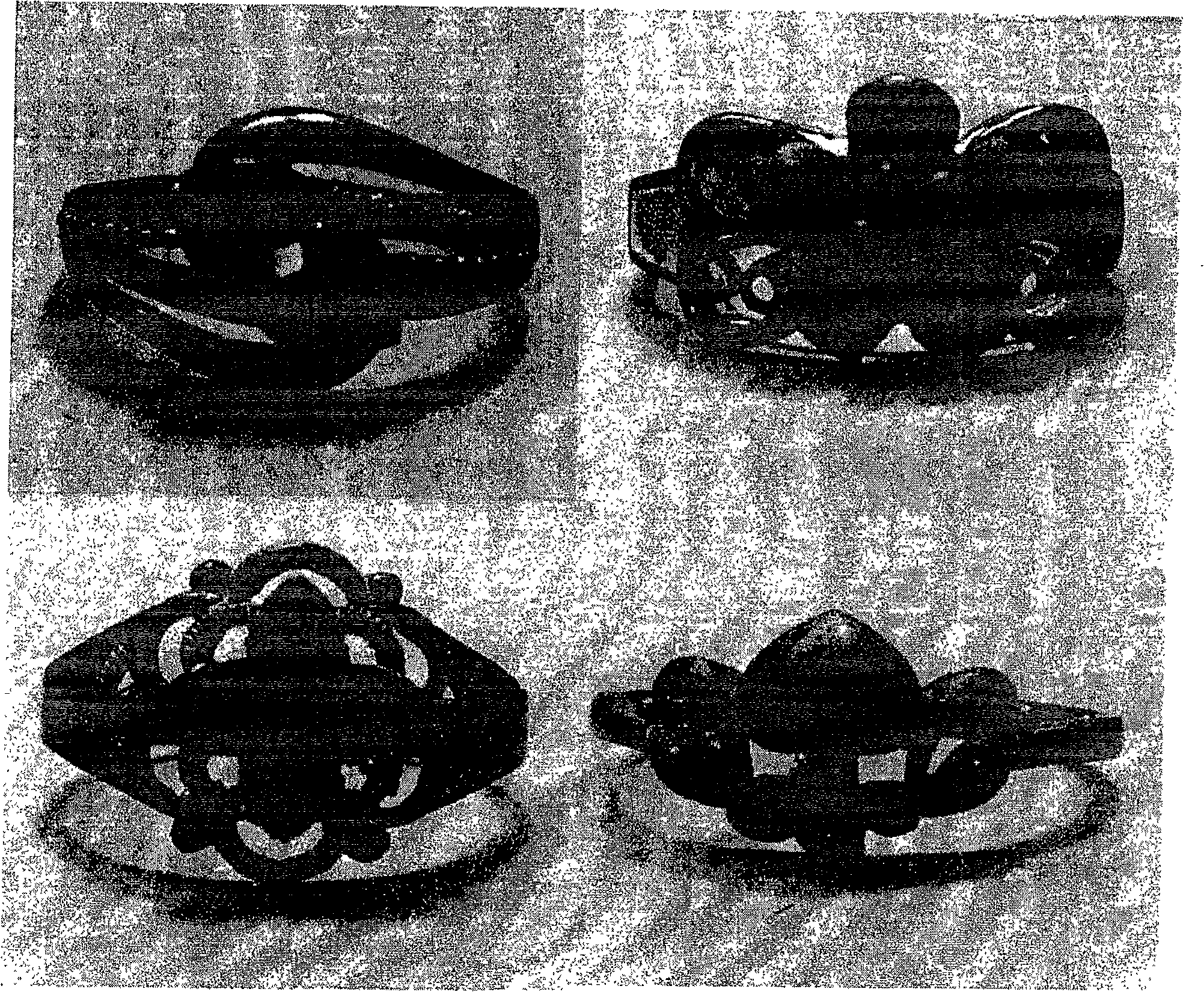

A technology of amorphous alloy and jewelry, which is applied in the manufacture of amorphous alloy jewelry and the field of nozzle equipment, which can solve the problems of high cost, difficult manufacturing, and difficult mold opening, etc., and achieve complete filling saving, low price, and various patterns Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with specific embodiments, but not limited to this embodiment.

[0020] The LaCeCoAl master alloy is coarsely crushed and loaded into a quartz nozzle. The alloy is melted by high-frequency induction heating and then spray-cast into a jewelry plaster mold. The specific steps are as follows:

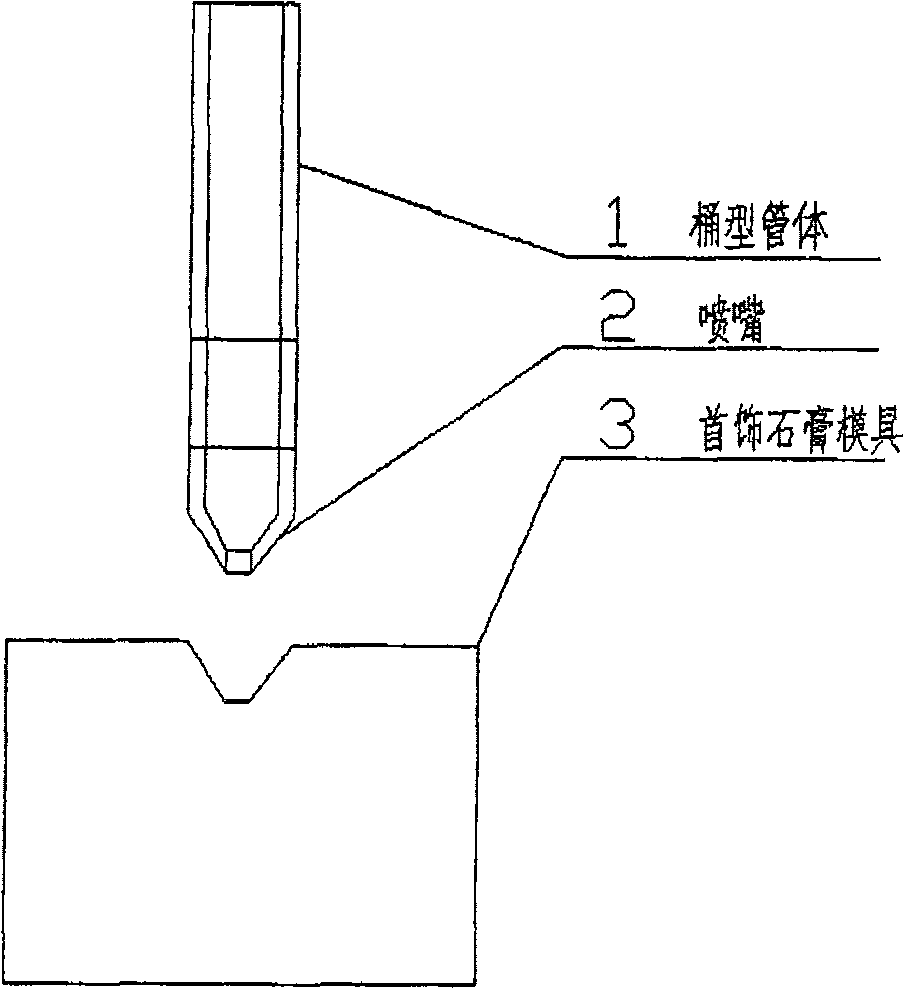

[0021] 1. Put the LaCeCoAl master alloy into a quartz nozzle after coarse crushing, place the quartz nozzle in a high-frequency induction furnace, and connect the upper end of the nozzle to an inert gas conduit;

[0022] 2. Carry out high-frequency induction heating to the alloy to about 50°C higher than the melting temperature of the alloy, and keep it warm;

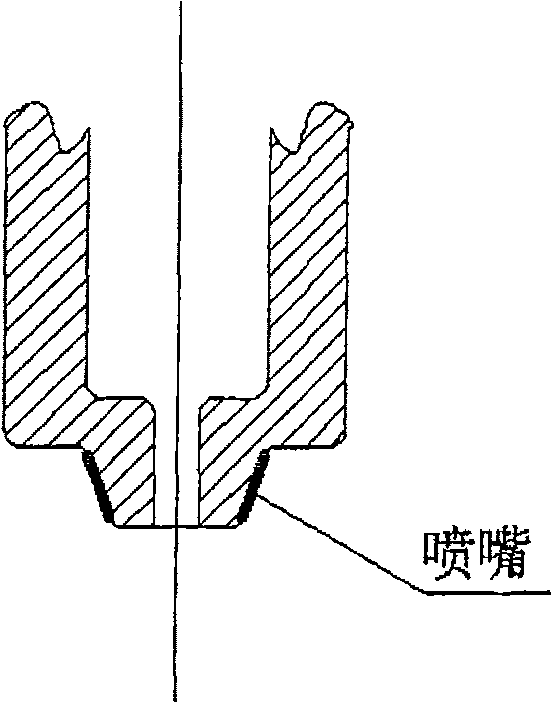

[0023] 3. Adjust the relative position of the quartz nozzle and the gypsum mold, insert the quartz nozzle into the injection port of the gypsum mold, and rotate relative to make the two fit tightly;

[0024] 4. Turn off the high-frequency induction power ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com