Technical method for forming semi-axle housing tube for large-diameter flange

A forming technology, a half-shaft sleeve technology, is applied in the field of plastic forming of metal parts to achieve the effects of ensuring coaxiality, reducing process difficulty, and reducing equipment investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

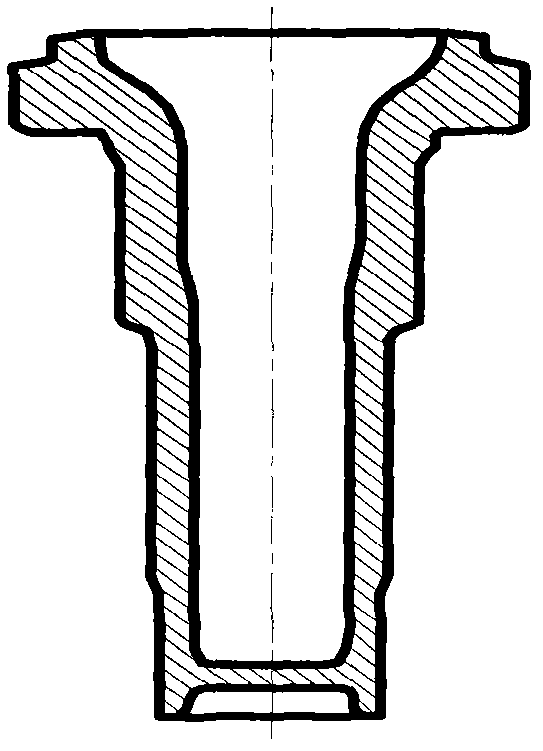

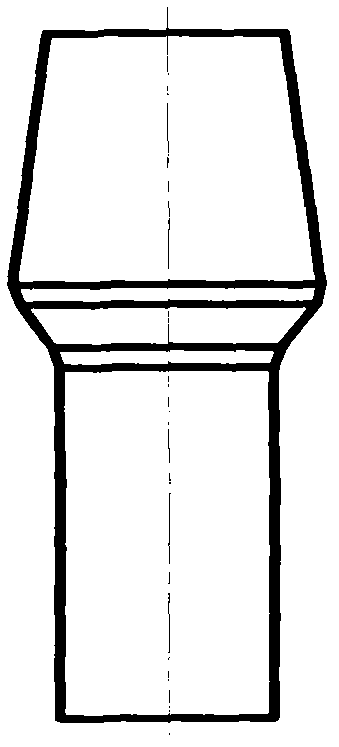

[0016] A technical method for forming a large-diameter flange half-shaft sleeve. The forming technical method uses hot-rolled round steel as a blank, and the blank is cut by sawing and then heated, and then heated by an extruder to complete the upsetting head Steps; Then the head flange of the half-shaft sleeve is swung-rolled and formed by the orbiting rolling machine; finally, the half-shaft sleeve forging is formed through one positive extrusion and one reverse extrusion forming step; in the actual implementation process of the patent In, such as figure 1 As shown, the shape of the forging is complicated. The outer diameter of the forging head flange is φ202mm, the rod is a stepped shaft, the minimum rod diameter is φ88mm, and the length of the forging is 371mm. In addition, the required stroke for inner hole forming and retrieval is required. The equipment stroke is greater than 1000mm, the mold closing height is greater than 700mm, and there is a large enough worktable; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com