Straight-tooth cylindrical gear radial extrusion die and method

A technology of spur gears and extrusion dies, which is applied to metal extrusion dies and other directions, can solve the problems of large forming load, difficult tooth cavity filling, and low die life, and achieves easy processing, ingenious structural design, and die service life. long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

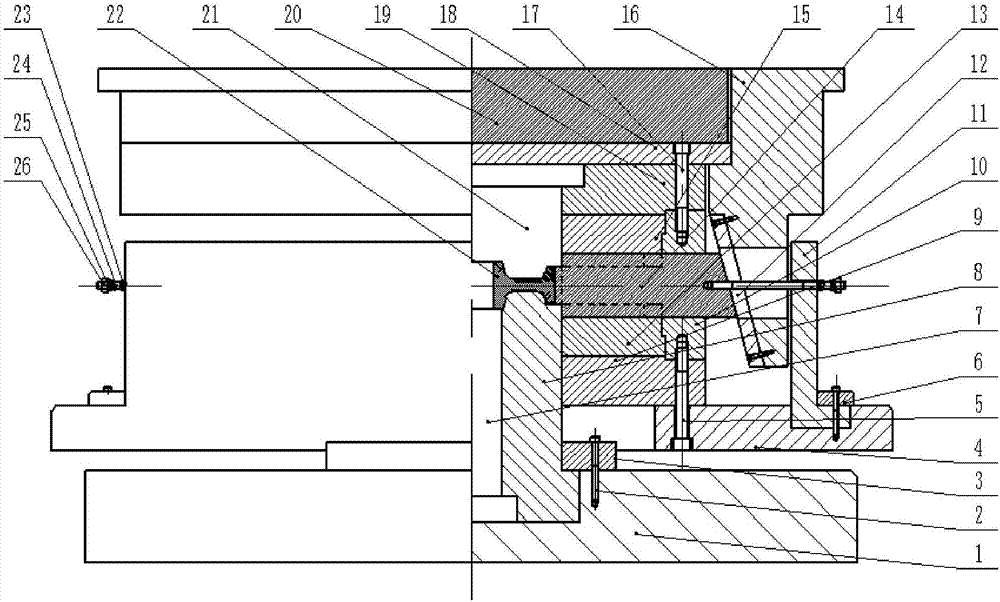

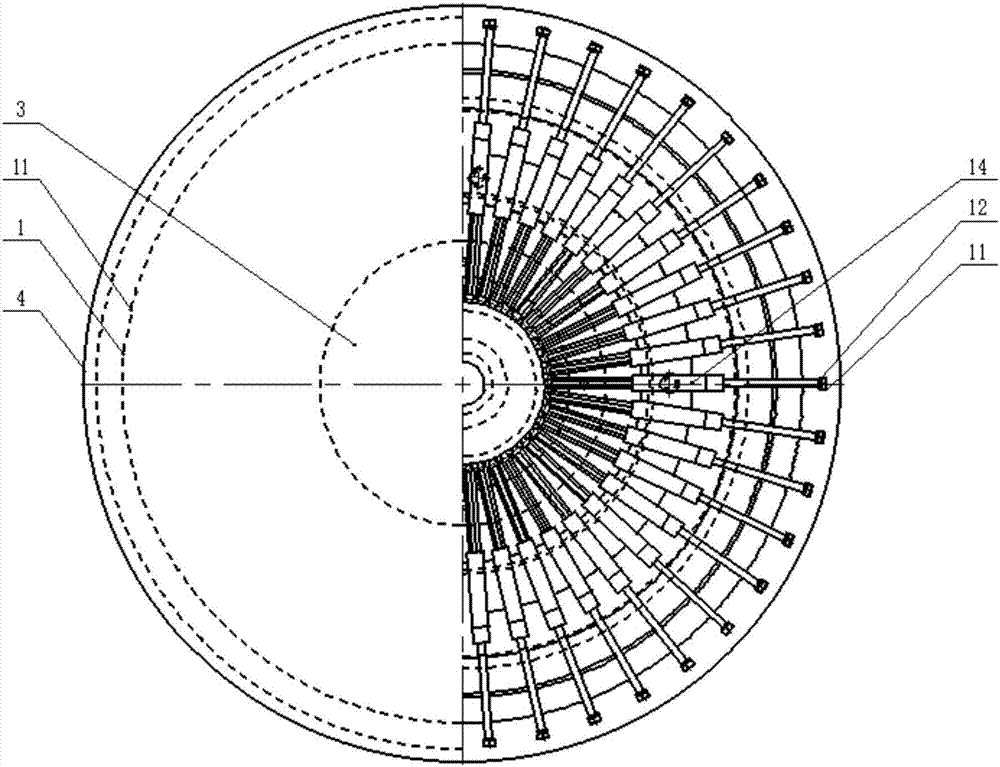

[0016] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0017] Such as Figure 1~2 As shown, the spur gear radial extrusion die of the embodiment of the present invention includes an upper die, a lower die, and a radial extrusion die fixed between the upper die and the lower die. The upper die includes: an elastic body 20, a pad Plate 18, upper die fixing plate 19, inclined ring plate 12, elastic body 20 is connected with the pressure motor beam, radial extrusion die includes side punch 14, upper and lower groove plates 15, 13, positioning ring 10, inclined ring plate 12. Cylindrical wedge 16, side mold fixing plate 9, outer sleeve 11, spring 23, bolt 24, elastic body 20 of the upper die is flatly embedded in the upper end of cylindrical wedge 16 of the radial extrusion die, and the cylinder oblique The wedge 16 is connected with the pressure motorized beam, the number of side punches matches the number of gear t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com