Heat-dissipating magnetic conductive sheet for wireless char and preparation method thereof

A wireless charging and heat dissipation technology, applied in the manufacture of inductors/transformers/magnets, preventing/reducing unwanted electric/magnetic influences, circuits, etc., can solve the problem of affecting the normal use of the magnetic sheet and increasing the overall thickness of the magnetic sheet , Not suitable for electronic products with relatively small volume, etc., to achieve the effect of improving shielding performance, reducing the loss of charging efficiency, and reducing the overall thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

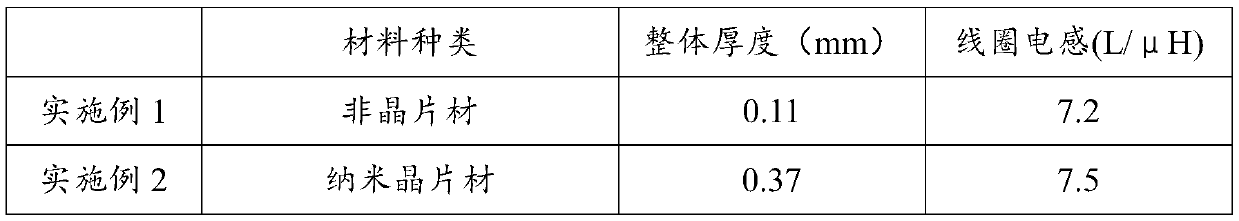

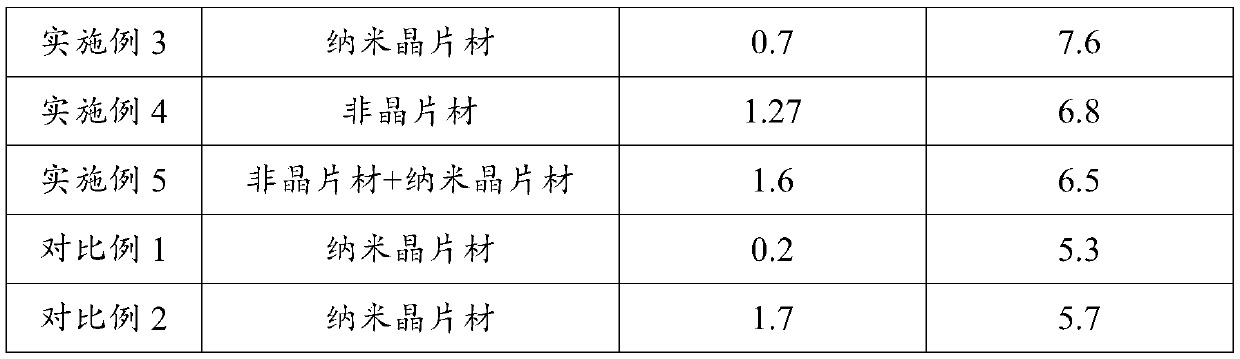

Embodiment 1

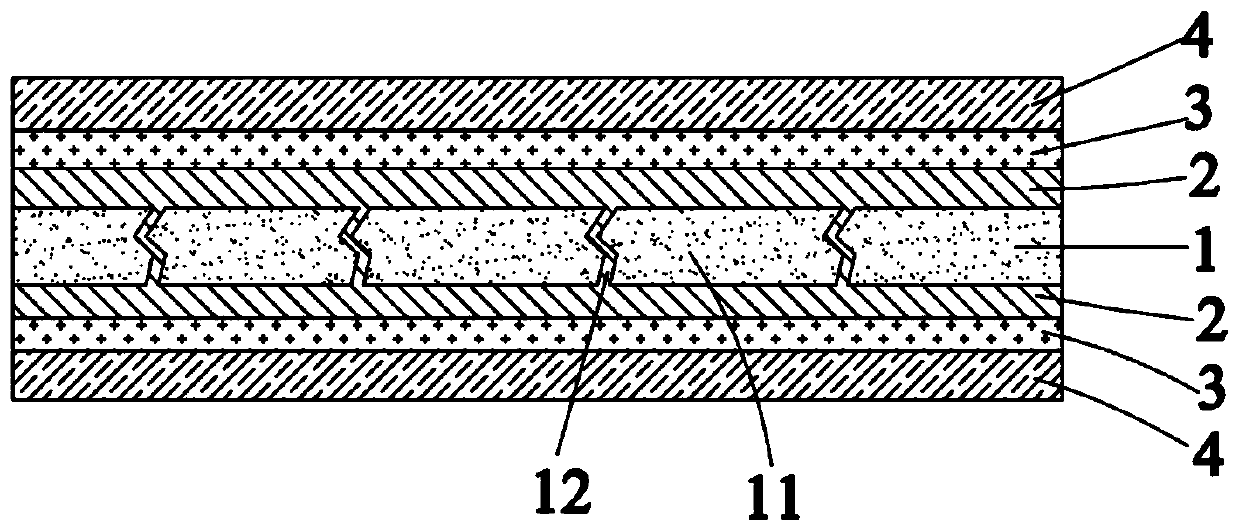

[0035] Preparation of heat-dissipating magnetic sheet for wireless charging:

[0036] 1) Take an iron-based amorphous material with a thickness of 0.01mm, and crack it to form a plurality of amorphous fragment units with a size of 0.5mm, and a gap is formed between two adjacent amorphous fragment units;

[0037] 2) According to the mass ratio, dissolve 30% epoxy resin and 15% acrylic resin in acetone solvent, then add 52% magnesium oxide and 3% m-phenylenediamine, and stir evenly to obtain an insulating and thermally conductive glue ;

[0038] 3) Immerse the cracked iron-based amorphous material in the insulating heat-conducting adhesive solution for 0.1s, then take it out and dry it for semi-curing, and form a semi-cured thickness of 0.02mm insulating and thermally conductive adhesive layer;

[0039] 4) Take a copper foil with a thickness of 0.02mm, and spray or deposit a graphite layer with a thickness of 0.01mm on any surface thereof;

[0040] 5) The side of the copper f...

Embodiment 2

[0042] Preparation of heat-dissipating magnetic sheet for wireless charging:

[0043] 1) Take an iron-based nanocrystalline sheet material with a thickness of 0.05mm, and crack it to form a plurality of nanocrystalline fragment units with a size of 2mm, and a gap is formed between two adjacent nanocrystalline fragment units;

[0044] 2) According to the mass ratio, dissolve 35% epoxy resin and 15% nitrile rubber in acetone solvent, then add 40% beryllium oxide and 10% m-phenylenediamine, and stir evenly to obtain an insulating heat-conducting glue ;

[0045] 3) Immerse the cracked iron-based nanocrystal sheet into the insulating heat-conducting adhesive for 1 second, then take it out and dry it, and perform semi-curing, forming a semi-cured thickness of 0.03 in the gap and the surface of the nanocrystalline fragment unit. mm insulation and heat conduction adhesive layer;

[0046] 4) Take a copper foil with a thickness of 0.1mm, and spray or deposit a graphite layer with a th...

Embodiment 3

[0049] Preparation of heat-dissipating magnetic sheet for wireless charging:

[0050] 1) Take a cobalt-based nanocrystalline sheet material with a thickness of 0.1 mm, and crack it to form a plurality of nanocrystalline fragment units with a size of 5 mm, and a gap is formed between two adjacent nanocrystalline fragment units;

[0051] 2) Dissolve 25% epoxy resin, 10% polyamideimide resin and 10% acrylic rubber in acetone solvent by mass ratio, then add 30% aluminum oxide, 20% silicon carbide and 5% m-phenylenediamine, stirred evenly to obtain insulating heat-conducting glue;

[0052] 3) Immerse the cracked cobalt-based nanocrystal sheet into the insulating heat-conducting adhesive for 5 seconds, then take it out and dry it, and perform semi-curing, forming a semi-cured thickness of 0.05 mm in the gaps and on the surface of the nanocrystalline fragment unit. mm insulation and heat conduction adhesive layer;

[0053] 4) Take a copper foil with a thickness of 0.2mm, and spray ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com