Compound mold for forging automobile crankshaft

A compound mold and crankshaft technology, which is applied in the manufacture of tools, casting molding equipment, casting molds, etc., can solve the problems of mold eccentric scrapping, mold folding, uneven distribution of forging liquid, etc., and achieve the effect of improving the quality of workpieces and filling them full

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

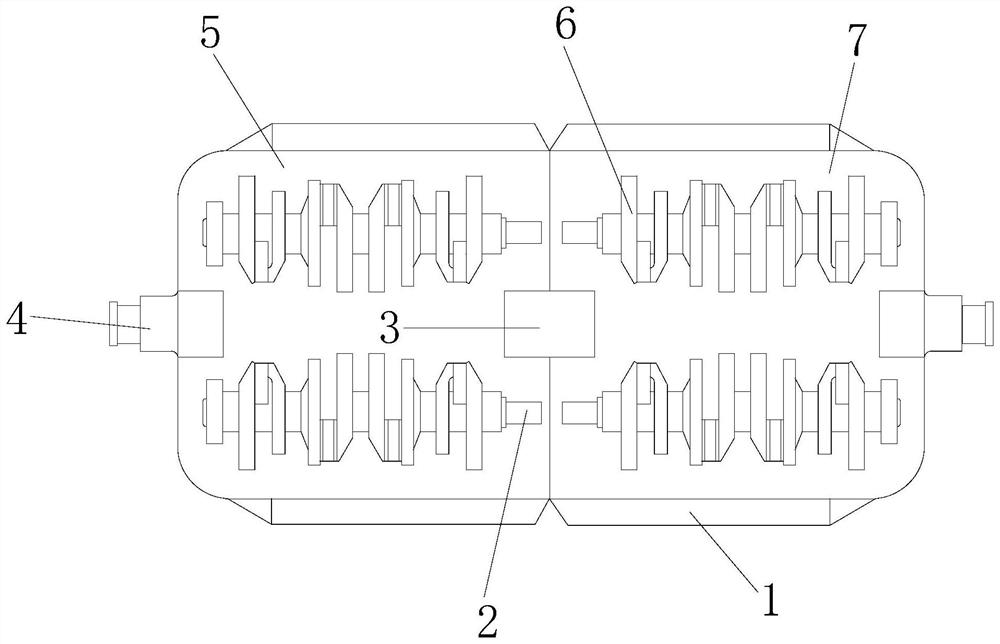

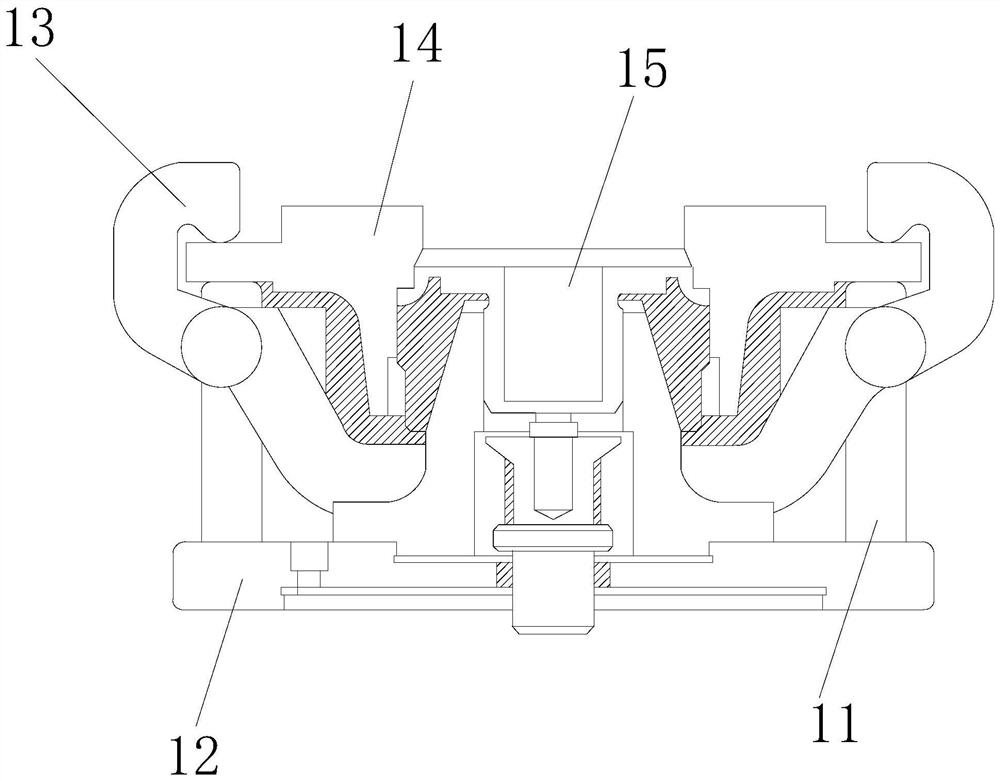

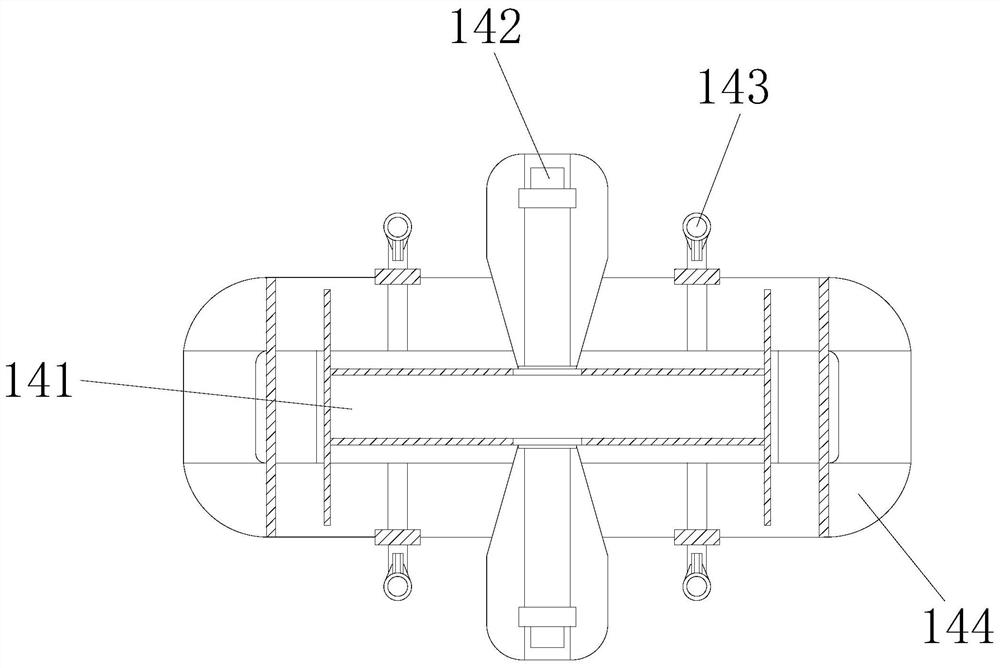

[0035] see figure 1 , the present invention provides a technical solution: an automobile crankshaft forging composite mold, the structure of which includes an adjusting device 1, a fixed shaft 2, a connecting fastener 3, a clamping rod 4, an upper mold 5, an injection cavity 6, and a lower mold 7. The adjusting device 1 is arranged at the bottom of the injection cavity 6, and the upper mold 5 and the lower mold 7 are all provided with an injection cavity 6, and the injection cavity 6 is fitted on the upper mold 5 and the lower mold 7, and the injection cavity 6 One end is provided with a fixed shaft 2, and the fixed shaft 2 is nested inside the injection molding cavity 6, and the upper mold 5 and the lower mold 7 are closely fitted by connecting fasteners 3, and the upper mold 5 and the lower mold 7 form an axis of symmetry structure, the upper mold 5 and the lower mold 7 are fastened through the clamping rod 4, and the clamping rod 4 is inserted and embedded in the side of t...

Embodiment 2

[0051] see figure 1 , the present invention provides a technical solution: an automobile crankshaft forging composite mold, the structure of which includes an adjusting device 1, a fixed shaft 2, a connecting fastener 3, a clamping rod 4, an upper mold 5, an injection cavity 6, and a lower mold 7. The adjusting device 1 is arranged at the bottom of the injection cavity 6, and the upper mold 5 and the lower mold 7 are all provided with an injection cavity 6, and the injection cavity 6 is fitted on the upper mold 5 and the lower mold 7, and the injection cavity 6 One end is provided with a fixed shaft 2, and the fixed shaft 2 is nested inside the injection molding cavity 6, and the upper mold 5 and the lower mold 7 are closely fitted by connecting fasteners 3, and the upper mold 5 and the lower mold 7 form an axis of symmetry structure, the upper mold 5 and the lower mold 7 are fastened through the clamping rod 4, and the clamping rod 4 is inserted and embedded in the side of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com