A wireless charging heat dissipation magnetic conductive film and its preparation method

A technology of wireless charging and magnetic conductive sheet, applied in the manufacture of inductors/transformers/magnets, preventing/reducing unwanted electric/magnetic influences, circuits, etc. The normal use of the sheet, increasing the overall thickness of the magnetic sheet, etc., to reduce the loss of charging efficiency, improve the shielding performance, and reduce the overall thickness of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

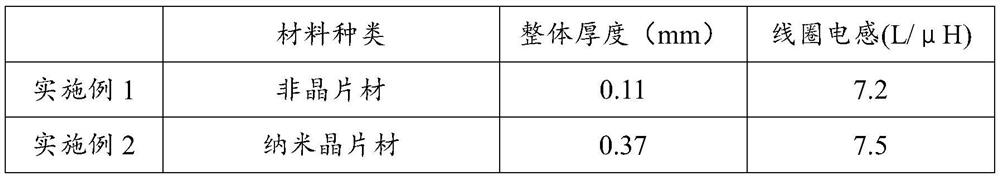

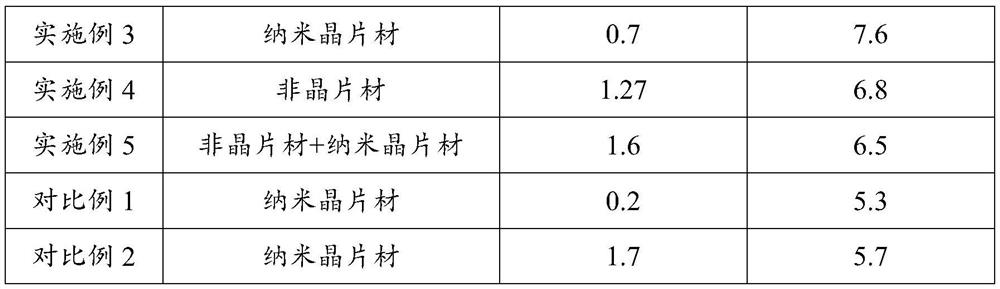

Embodiment 1

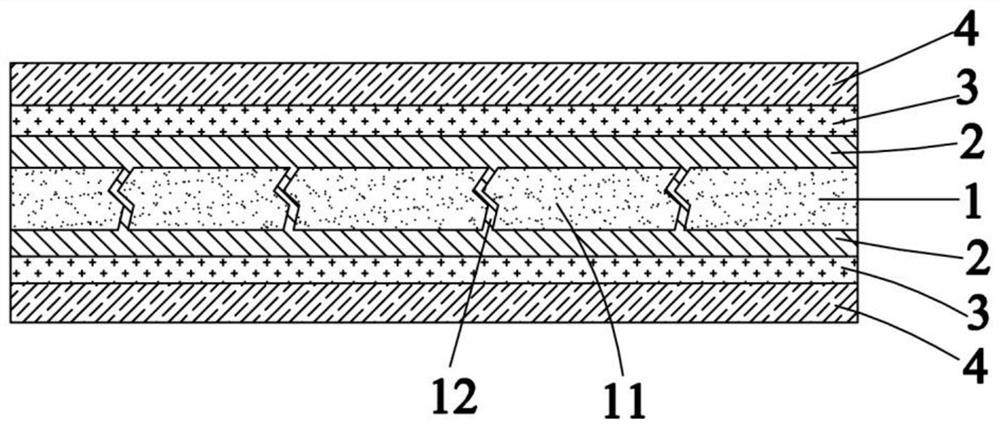

[0035] Preparation of heat-dissipating magnetic sheet for wireless charging:

[0036] 1) Take an iron-based amorphous material with a thickness of 0.01mm, and crack it to form a plurality of amorphous fragment units with a size of 0.5mm, and a gap is formed between two adjacent amorphous fragment units;

[0037] 2) According to the mass ratio, dissolve 30% epoxy resin and 15% acrylic resin in acetone solvent, then add 52% magnesium oxide and 3% m-phenylenediamine, and stir evenly to obtain an insulating heat-conducting glue ;

[0038] 3) Immerse the iron-based amorphous material after cracking treatment in the insulating heat-conducting adhesive solution for 0.1s, then take it out and dry it for semi-curing, and form a semi-cured thickness of 0.02mm insulating and thermally conductive adhesive layer;

[0039] 4) Take a copper foil with a thickness of 0.02mm, and spray or deposit a graphite layer with a thickness of 0.01mm on any surface thereof;

[0040] 5) The side of the ...

Embodiment 2

[0042] Preparation of heat-dissipating magnetic sheet for wireless charging:

[0043] 1) Take an iron-based nanocrystalline sheet material with a thickness of 0.05mm, and crack it to form a plurality of nanocrystalline fragment units with a size of 2mm, and a gap is formed between two adjacent nanocrystalline fragment units;

[0044] 2) According to the mass ratio, dissolve 35% epoxy resin and 15% nitrile rubber in acetone solvent, then add 40% beryllium oxide and 10% m-phenylenediamine, and stir evenly to obtain an insulating heat-conducting glue ;

[0045] 3) Immerse the cracked iron-based nanocrystal sheet into the insulating heat-conducting adhesive for 1 second, then take it out and dry it, and perform semi-curing, forming a semi-cured thickness of 0.03 in the gap and the surface of the nanocrystalline fragment unit. mm insulation and heat conduction adhesive layer;

[0046] 4) Take a copper foil with a thickness of 0.1mm, and spray or deposit a graphite layer with a th...

Embodiment 3

[0049] Preparation of heat-dissipating magnetic sheet for wireless charging:

[0050] 1) Take a cobalt-based nanocrystalline sheet material with a thickness of 0.1 mm, and crack it to form a plurality of nanocrystalline fragment units with a size of 5 mm, and a gap is formed between two adjacent nanocrystalline fragment units;

[0051] 2) Dissolve 25% epoxy resin, 10% polyamideimide resin and 10% acrylic rubber in acetone solvent by mass ratio, then add 30% aluminum oxide, 20% silicon carbide and 5% m-phenylenediamine, stirred evenly to obtain insulating heat-conducting glue;

[0052] 3) Immerse the cracked cobalt-based nanocrystal sheet into the insulating heat-conducting adhesive for 5 seconds, then take it out and dry it, and perform semi-curing, forming a semi-cured thickness of 0.05 mm in the gaps and on the surface of the nanocrystalline fragment unit. mm insulation and heat conduction adhesive layer;

[0053] 4) Take a copper foil with a thickness of 0.2mm, and spray ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com