Copper brazing manufacturing method of fuel distribution pipe and radial connecting part of main pipe

A technology of radial connection and manufacturing method, which is applied in the direction of manufacturing tools, welding equipment, engine components, etc., can solve the problems of affecting the quality of welds, insufficient filling of internal gaps, and high energy, so as to ensure the consistency of weld quality and guarantee The effect of filling full and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

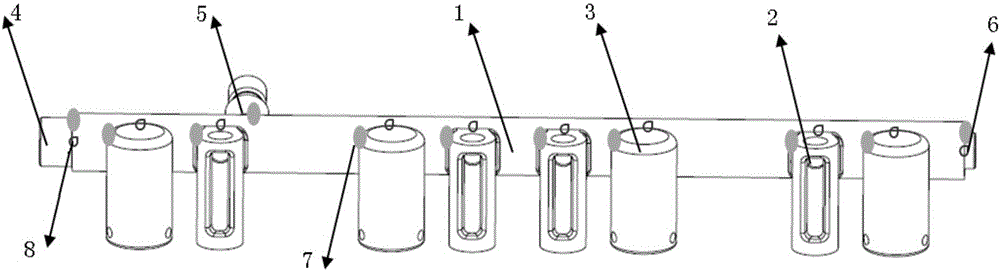

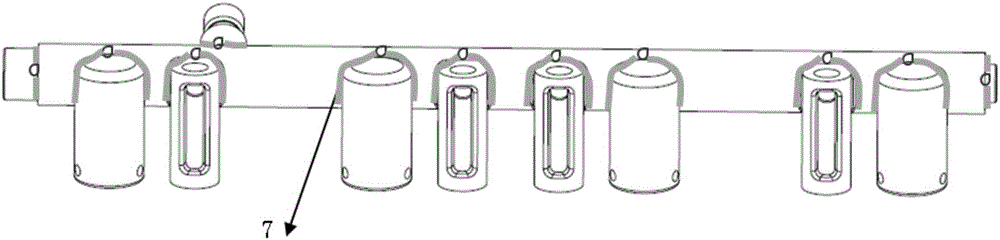

[0061] Copper brazing manufacturing methods for fuel distribution pipes such as Figure 5 As shown, the fuel distribution pipe includes a main pipe 1, an axial connecting part of the main pipe, and a radial connecting part of the main pipe; the manufacturing process steps are as follows:

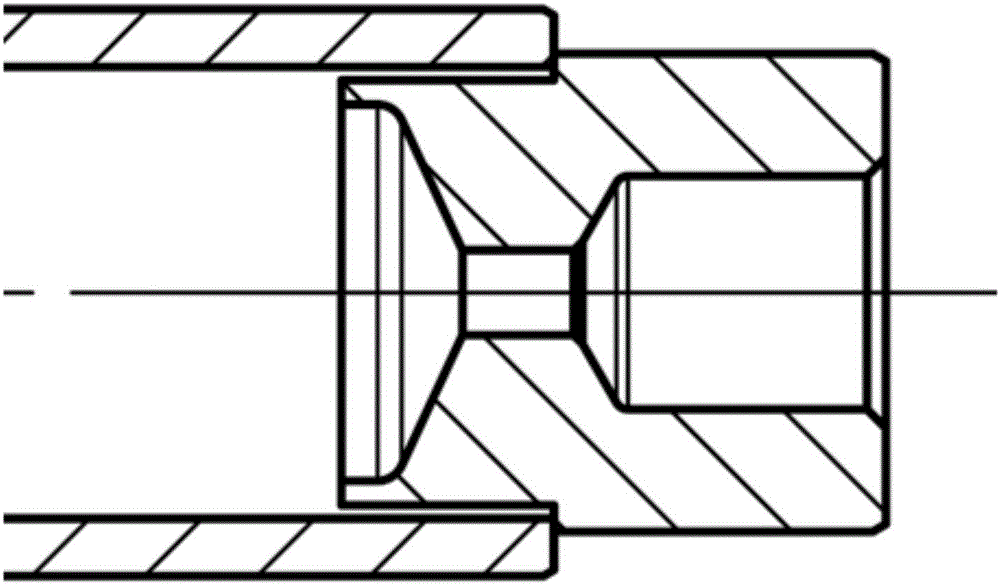

[0062] 1. If Figure 7 As shown, a copper ring 11 is built in the end of the main pipe 1 or a copper ring 11 is placed outside the axial connecting part of the main pipe, and then the axial connecting part of the main pipe is pressed and positioned on the end of the main pipe 1 in the axial direction, and the axial connecting part of the main pipe is connected with the The main pipes 1 are connected and fixed through partial interference fit, and the copper ring 11 is squeezed between the main pipe axial connection parts and the main pipe 1;

[0063] Such as Figure 8 , Figure 9 As shown, the radial connecting part of the main pipe has a circular arc fitting surface that matches the oute...

Embodiment 2

[0076] Based on the copper brazing manufacturing method of the fuel distribution pipe of embodiment 1, in step 2, a local brazing method is adopted, that is, the fuel distribution pipe does not enter the brazing furnace as a whole at the same time, but the axial connection parts of the main pipe, the radial direction of the main pipe Local brazing heating is carried out in batches and successively at the connection and fixing positions of the connecting parts and the main pipe.

[0077] The copper brazing manufacturing method of the fuel distribution pipe of the second embodiment adopts the local brazing method, and performs local heating in batches and sequentially at the joints of each part, so that the built-in copper ring or copper sheet melts at high temperature and penetrates from the inside to the outside to fill the entire weld. gap. According to the Hall-Page law, the smaller the grain size of the metal material, the higher the material strength. This process avoids t...

Embodiment 3

[0079] Based on the fuel oil distribution pipe copper brazing manufacturing method of embodiment two, such as Figure 6 As shown, the axial connecting parts of the main pipe are a sensor joint 4 and an end cover 6;

[0080] The radial connecting parts of the main pipe include a pipe joint 5, a bracket 2 and an injector seat 3;

[0081] In step 1, a copper ring is built into the end of the main pipe or a copper ring 11 is placed outside the sensor connector 4 and the end cap 6, and then the sensor connector 4 and the end cap 6 are pressed and positioned on both ends of the main pipe 1 along the axial direction, and the sensor connector 4 and the end cover 6 and the main pipe 1 are connected and fixed through partial interference fit, and the copper ring 11 is squeezed between the sensor joint 4 or the end cover 6 and the main pipe 1;

[0082] The pipe joint 5, the bracket 2 and the fuel injector seat 3 each have an arc fitting surface matching the outer wall of the main pipe 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com