Method and sand core assembly for rapid casting of distributor of engine for large ships

A marine engine and rapid casting technology, which is applied in the direction of cores, mold components, casting molding equipment, etc., can solve the problems of limited core position, poor core assembly accuracy, shrinkage and porosity, and achieve the goal of ensuring quality and sealing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

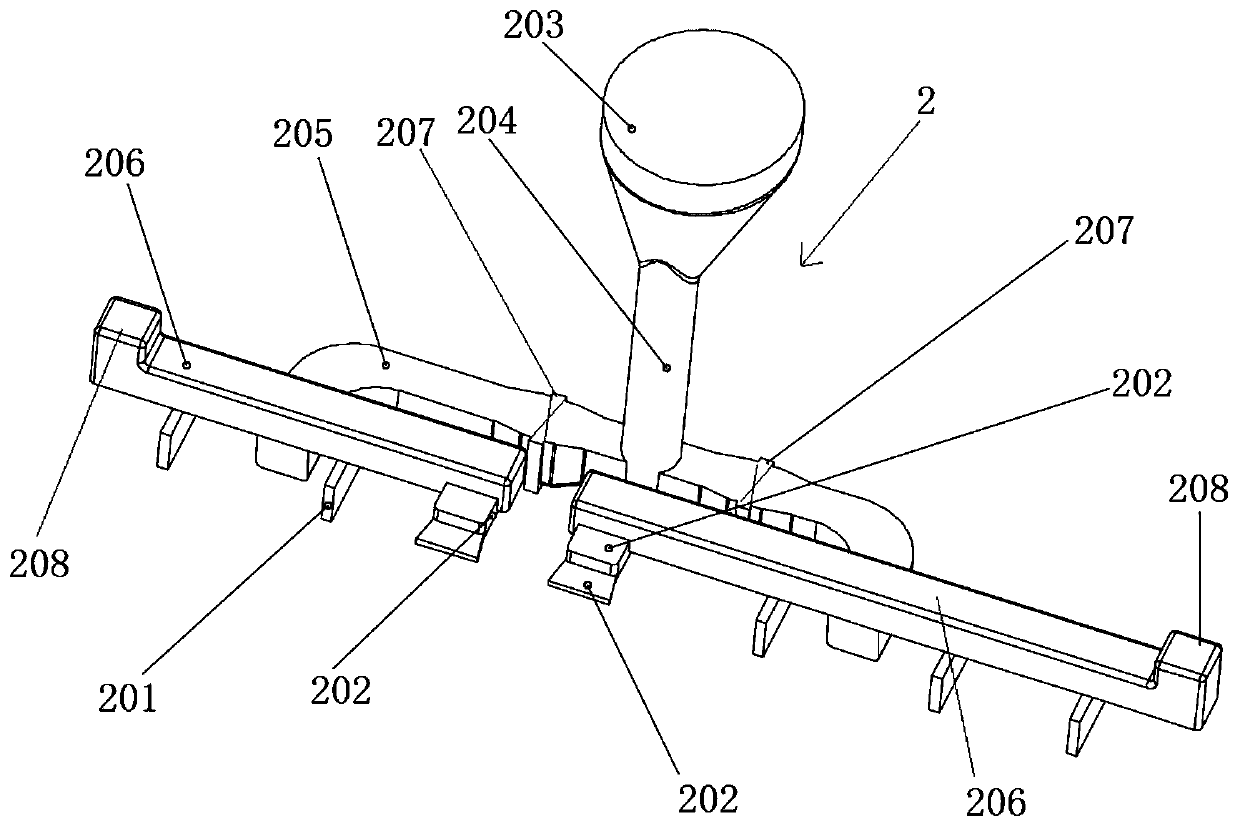

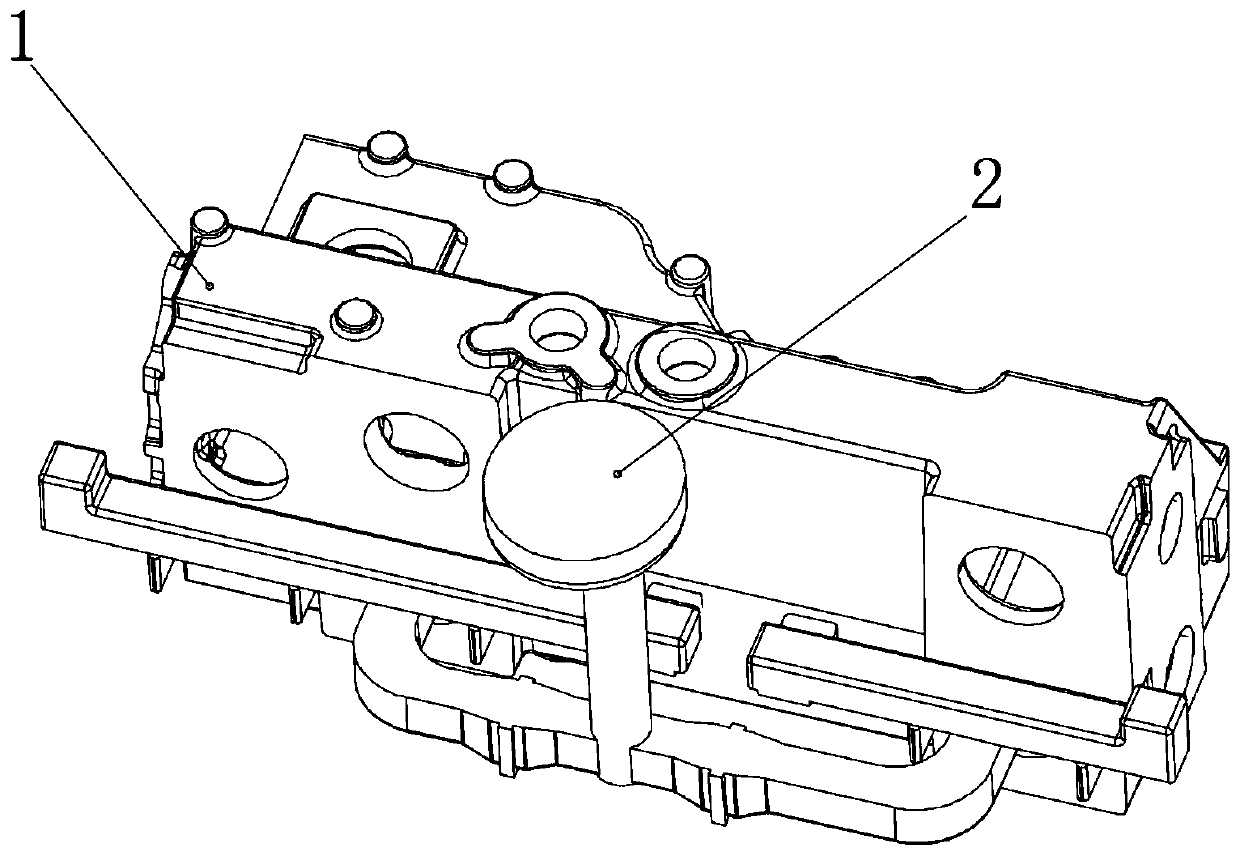

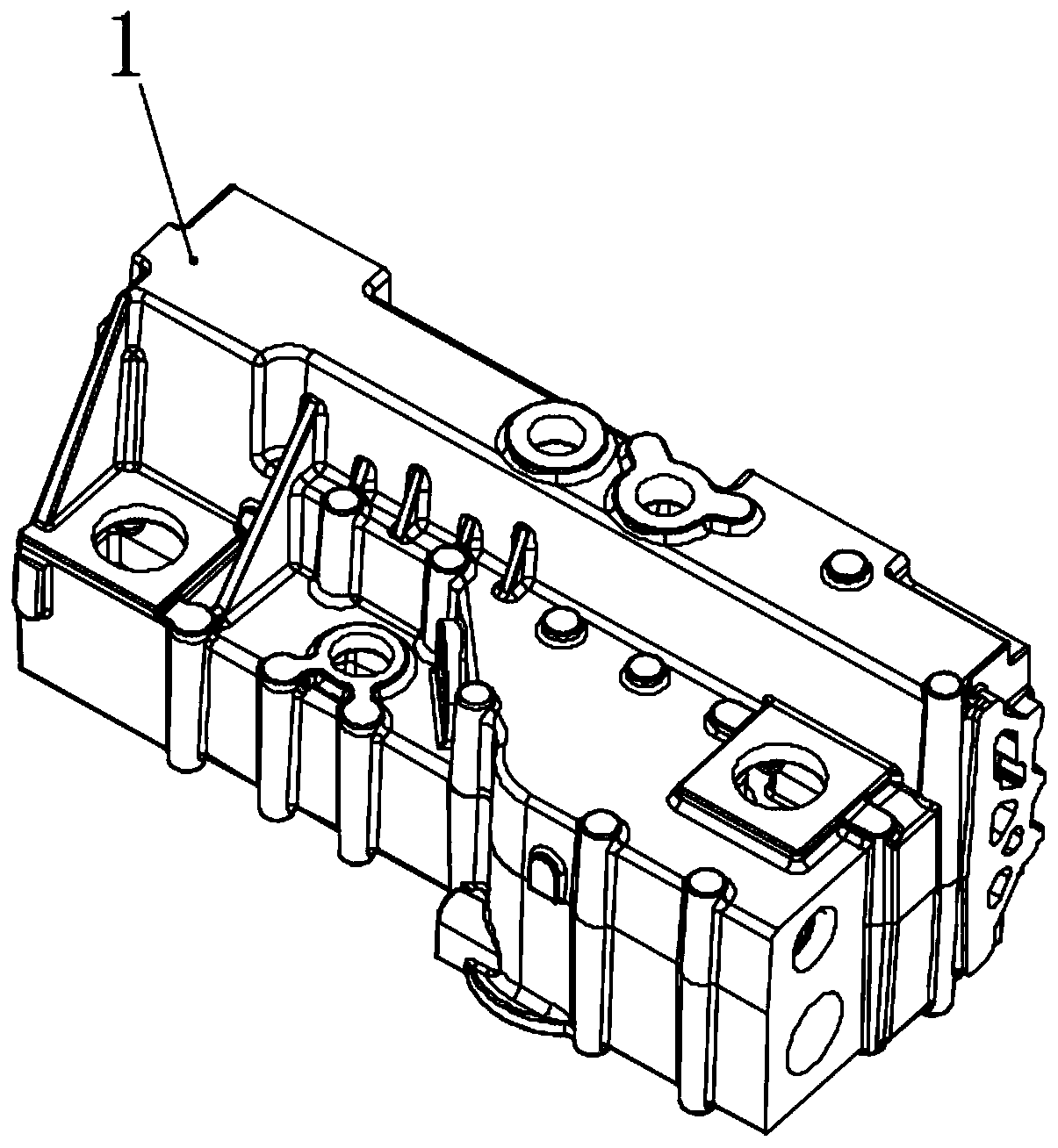

[0042] The specific embodiment of the present invention is like this: as Figure 1-15As shown, a method for rapid casting of a distribution body of a large marine engine, the casting method includes: setting a pouring runner 2 on one side of the sand core group, the cavity in the sand core group is the mold cavity of the distribution body 1, and the pouring flow The vertical inner gate 201 is set on the channel 2 to align with the vertical interlayer cavity in the cavity of the sand core set and the horizontal inner gate 202 is set to align with the transverse interlayer cavity in the cavity of the sand core set, and the molten iron flows into the pouring The runner 2 fills the mold cavity of the sand core group throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com