A vacuum casting device and casting method for room temperature curing epoxy resin

An epoxy resin and vacuum pouring technology, which is applied in the field of epoxy resin vacuum pouring, can solve the problems of affecting the pouring rate, inconvenient operation, and slow gravity injection speed, etc., to effectively control the resin temperature, improve the defoaming efficiency, and ensure The effect of resin filling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

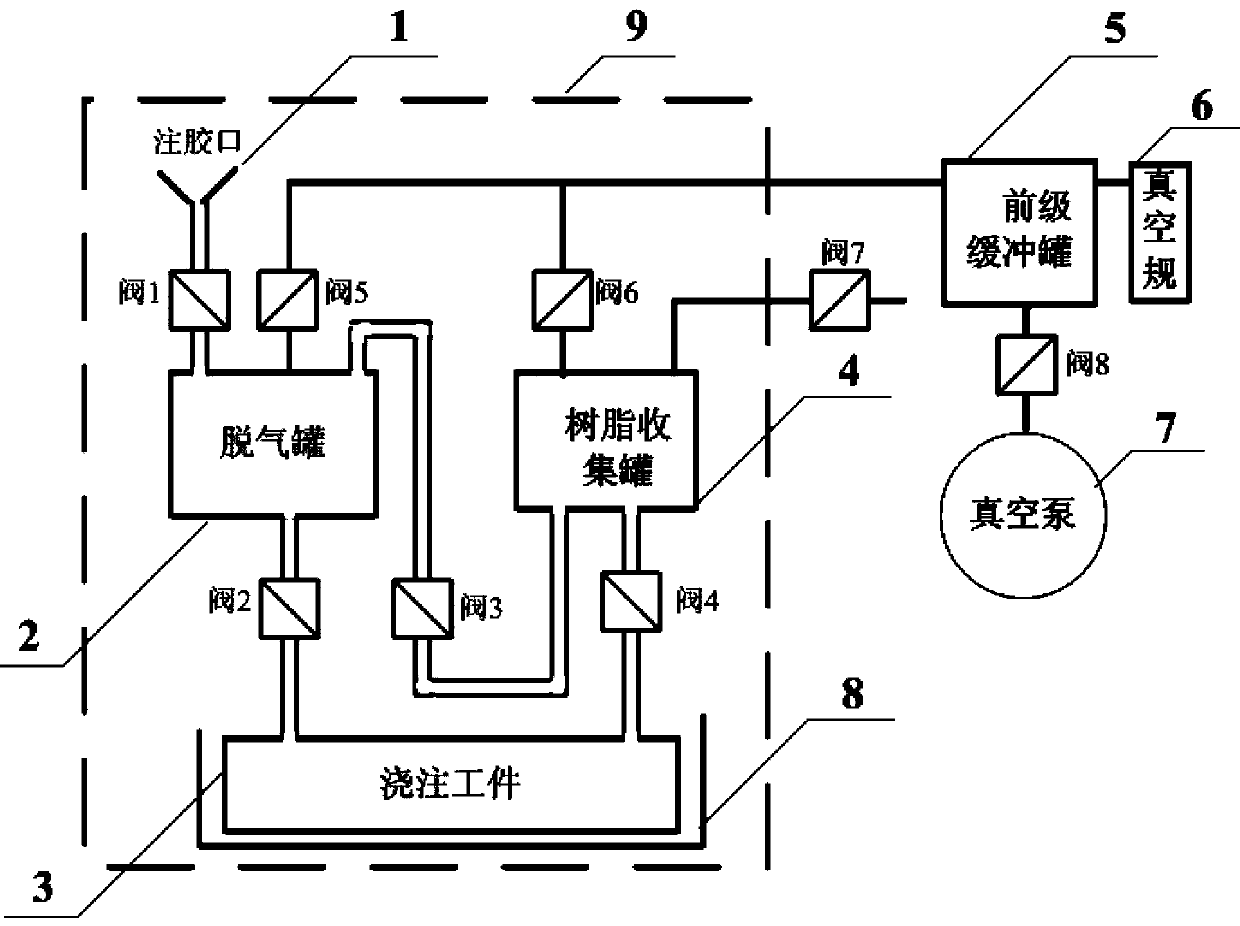

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0021] The present invention is mainly aimed at the vacuum casting of room temperature curing epoxy resin, which is characterized by short curing time. After the resin is added with a curing agent, an exothermic reaction begins, which accelerates the curing of the resin.

[0022] refer to figure 1 As shown, a vacuum casting device for room temperature curing epoxy resin can be used for vacuum casting of room temperature curing epoxy resin with short curing time and large amount of resin, including environmental temperature adjustment parts, glue path components and vacuum pressure adjustment parts; The ambient temperature adjustment part is composed of a semi-closed operation box 9 and an air conditioner, which provides a constant temperature working environment of 16-20°C for the glue path assembly; , the pouring workpiece 3 and the resin co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com