Method for manufacturing cross ring of scroll compressor

The technology of a scroll compressor and a manufacturing method, which is applied in the field of compressors, can solve the problems of low production efficiency, high manufacturing cost, low qualification rate, etc., so as to improve production efficiency, improve qualification rate, improve wear resistance and strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following are specific embodiments of the present invention and the accompanying drawings to further describe the technical solutions of the present invention, but the present invention is not limited to these embodiments.

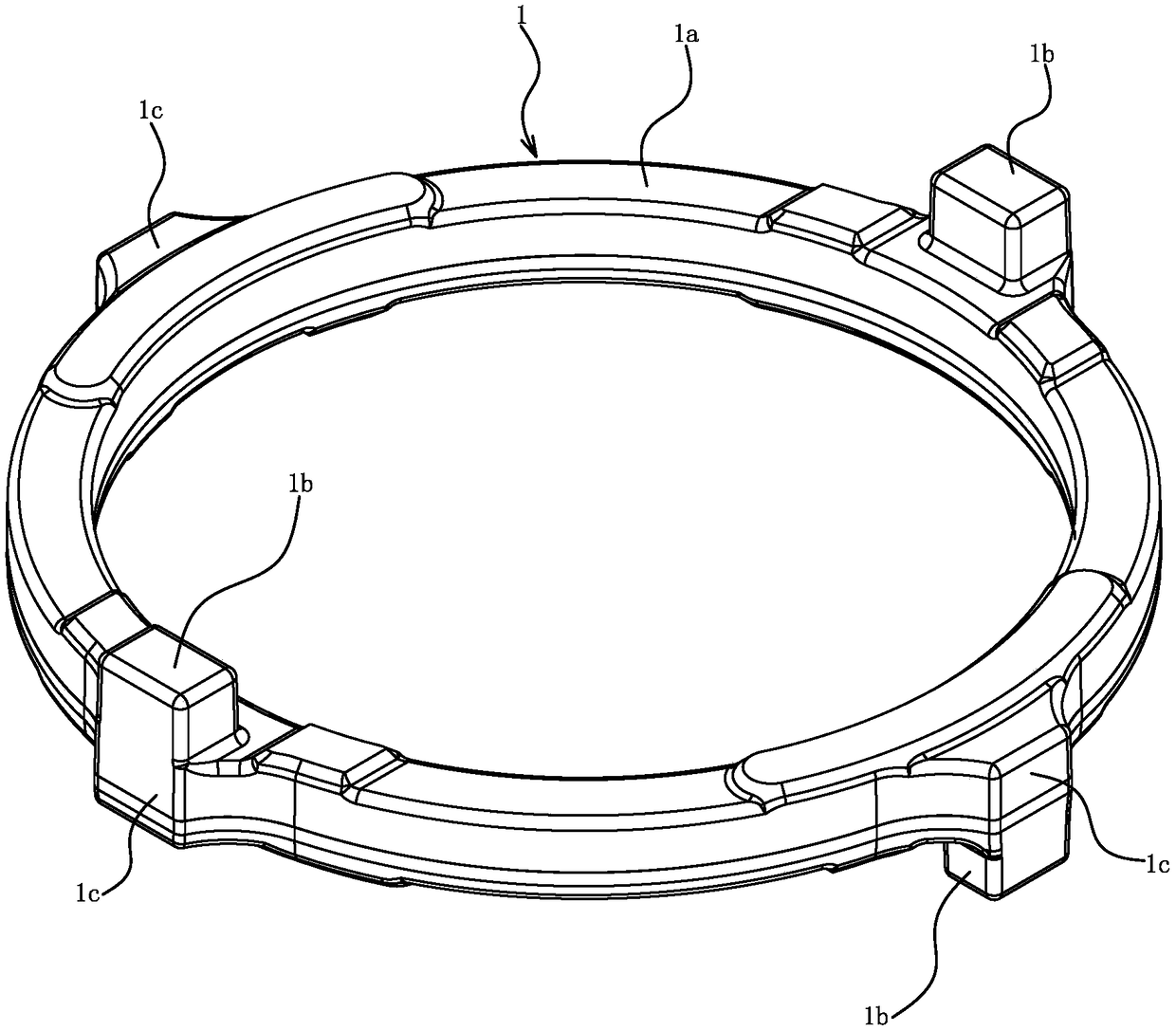

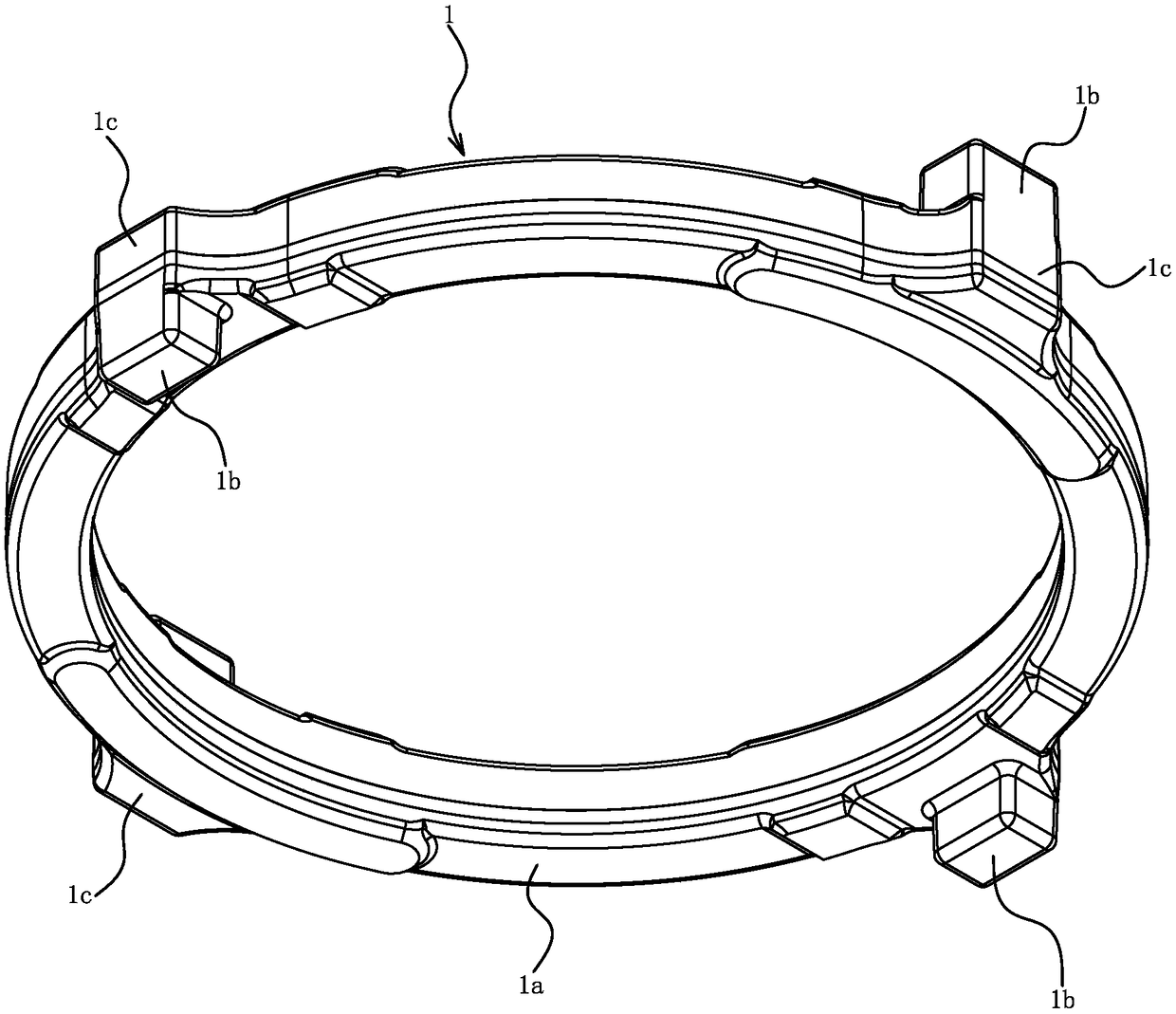

[0023] like figure 1 and figure 2 As shown, the cross ring blank 1 is annular, and the cross ring blank 1 includes a ring portion 1a and four key bodies 1b, and the four key bodies 1b are evenly distributed in the circumferential direction around the axis of the ring portion 1a; The two key bodies 1b face upward, the other two key bodies 1b face downward, and the two upward key bodies 1b and the two downward key bodies 1b are staggered; most of the key bodies 1b are located outside the ring portion 1a, The key body 1b is not only directly connected to the upper surface of the annular portion 1a, but also connected to the outer surface of the annular portion 1a through the key root portion 1c.

[0024] The manufacturing method of the scroll co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com