A combination core of pressurized multi-channel pipe splitting mold

A multi-channel pipe and split die technology, applied in the field of pressurized multi-channel pipe split die combined core field, can solve the problems of insufficient extrusion filling, fluctuating pipe wall thickness, easy breakage of core needles, etc. The effect of pressure, improving molding quality, and improving pressure bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

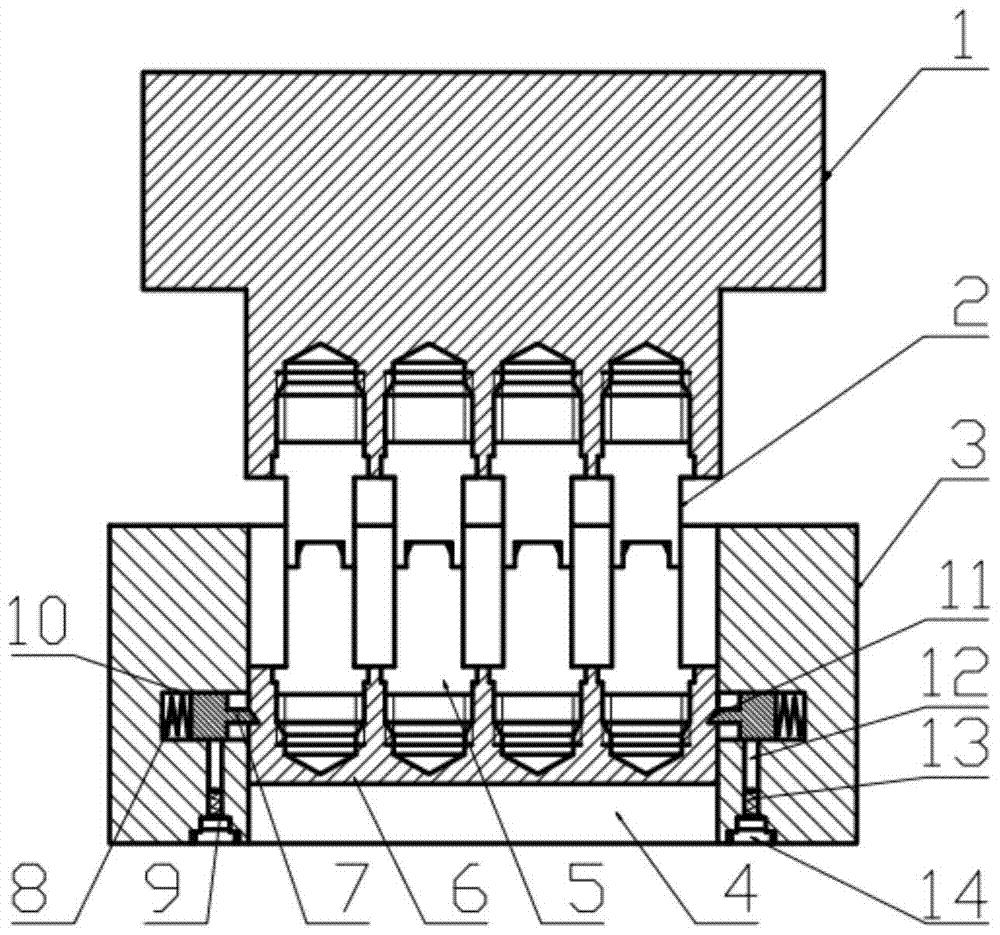

[0031] Such as figure 1 and Figure 5 As shown, a combined mold core of a pressurized multi-channel pipe splitting mold includes a mold core 1, a lower mold 3 and a lower mold support plate 6; the mold core 1 is located at the upper part, and the lower mold 3 is located at the lower part, forming The periphery of combined mold core; The center of described lower mold 3 has the lower mold through hole 4 of cuboid; The shape and size of mold through hole 4 are identical, so that the outer wall of lower mold support plate 6 can be close to the inner wall of lower mold 3; the thickness of described lower mold support plate 6 is less than the thickness of lower mold 3, so that lower mold support plate 6 can Placed in the lower die through hole 4 of the lower die 3.

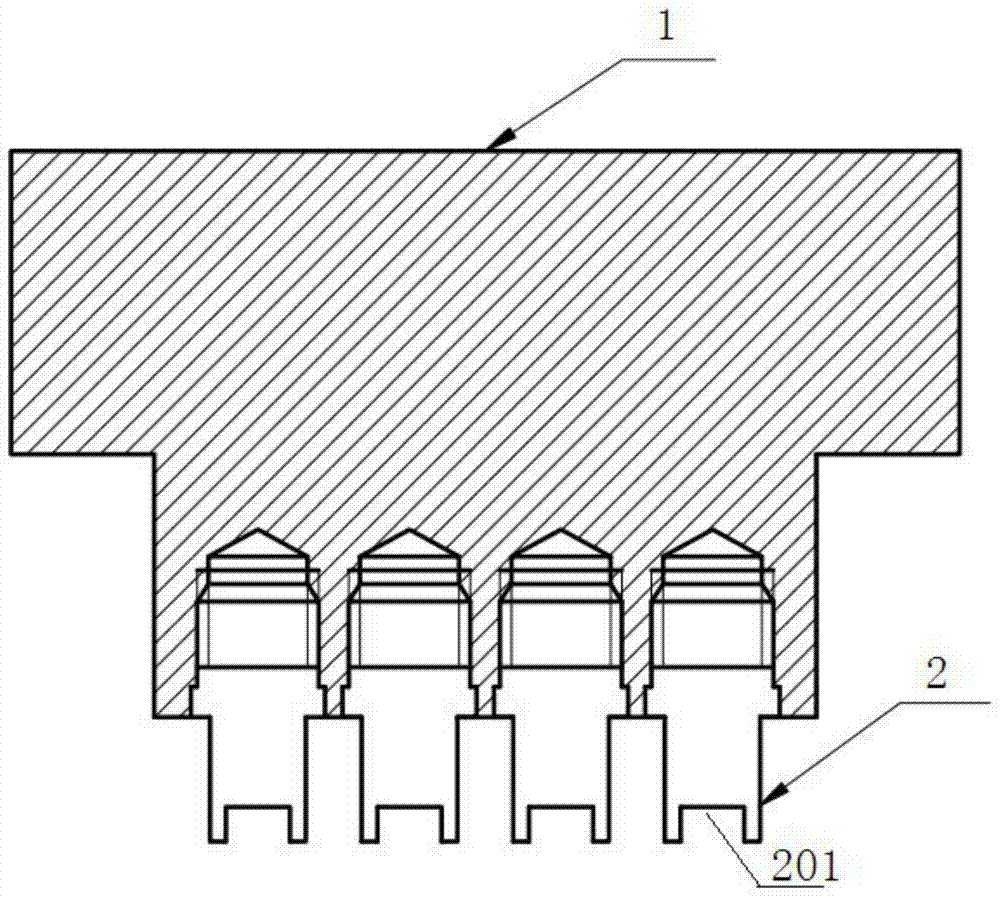

[0032] Such as image 3 As shown, the bottom of the core 1 is equipped with a plurality of equidistantly arranged upper core pins 2; the upper core pins 2 and the core 1 are threaded, and the upper core pins 2 conta...

Embodiment 2

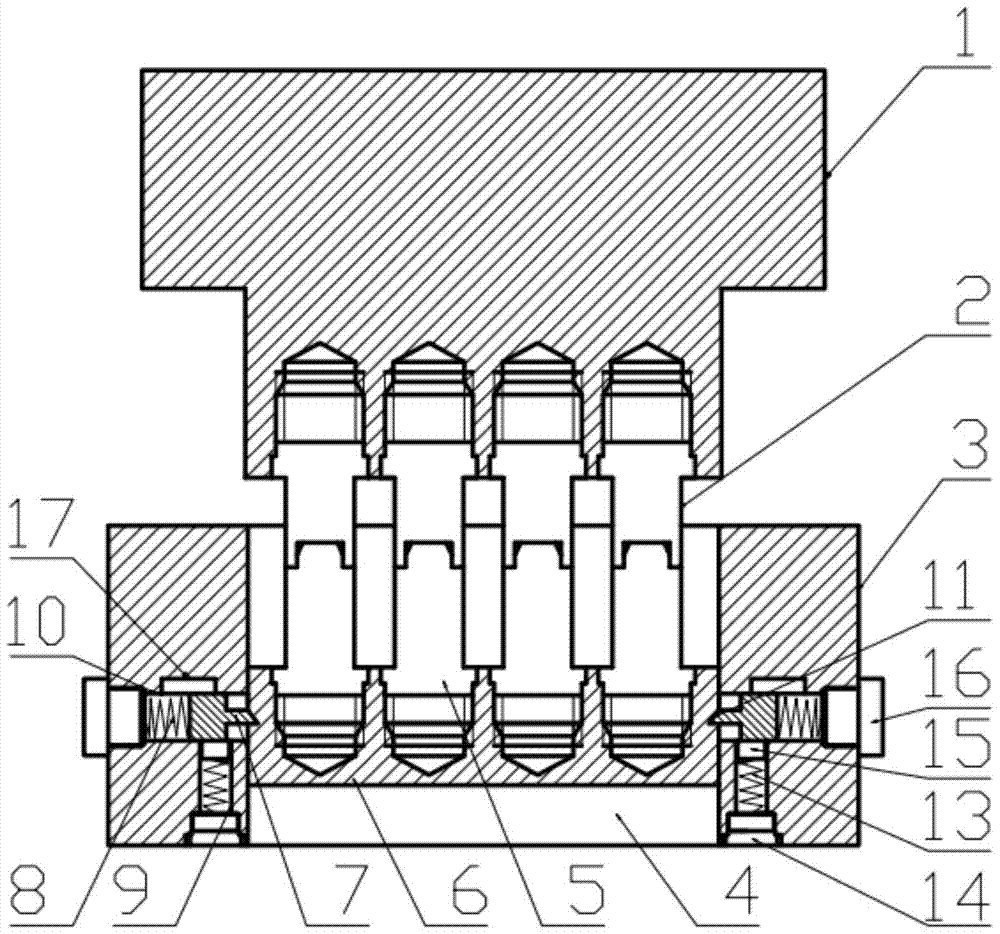

[0038] Such as figure 2 As shown, the inner wall of the lower mold 3 is symmetrically provided with two transverse sliding grooves 10, the lower mold support plate 6 is a cuboid plate; the base 702 is a cuboid base; the sliding groove 10 is a front section cuboid , the through groove of the terminal threaded hole; the bolt 16 is arranged in the threaded hole; the end of the spring 8 is against the bolt 16; the bottom of the sliding groove 10 is provided with a connected square hole 9, and the bottom of the square hole 9 is provided with a threaded hole A stop bolt 14 is arranged in the threaded hole, and the stop spring 13 is connected to the top of the stop bolt 14, and the top of the stop spring 13 is against the ejector block 15; the top of the sliding groove 10 has a slider card Groove 17; the horizontal dimension of the slider locking groove 17 is greater than the horizontal dimension of the base 702 of the boss slider 7, such as Figure 7 As shown, the horizontal dista...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com