Extrusion device for shortening blank friction flow path

A technology of friction flow and extrusion device, which is applied in the field of extrusion device to shorten the friction flow path of billet, which can solve the problems of deteriorating the use conditions of tools and molds, increasing the load of extrusion equipment, hindering metal flow, etc., and reducing the extrusion load and deformation temperature, energy saving, and the effect of reducing the rotation angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

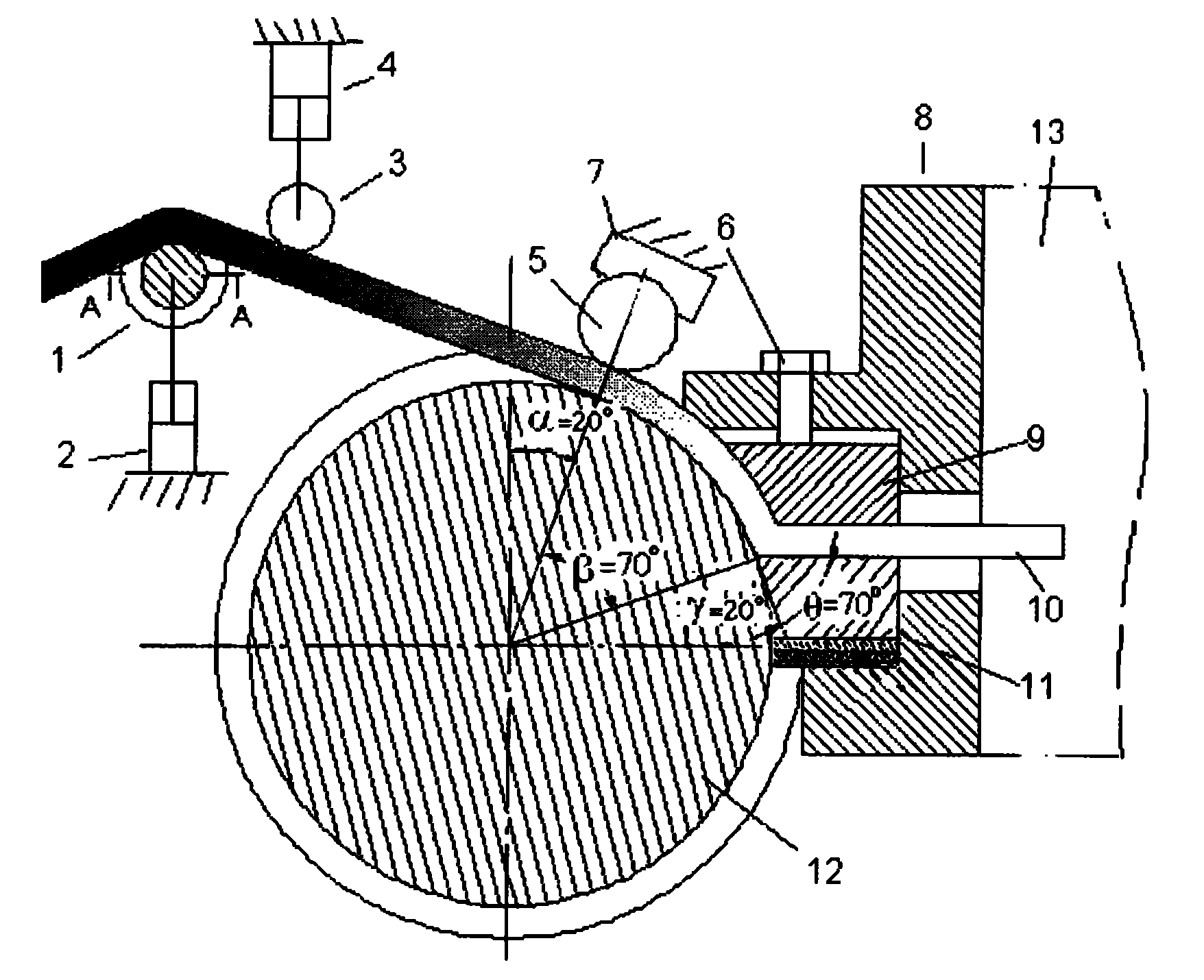

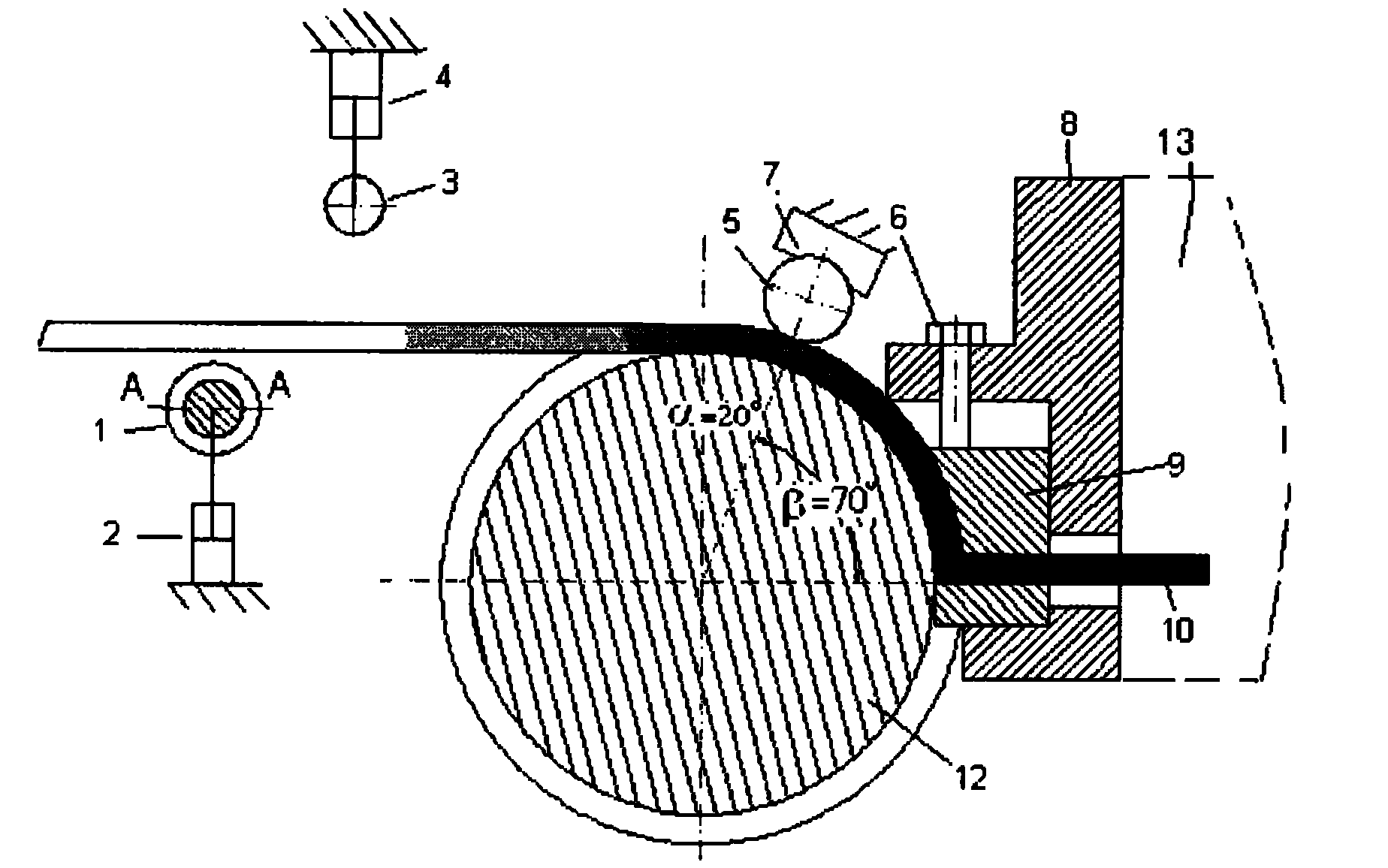

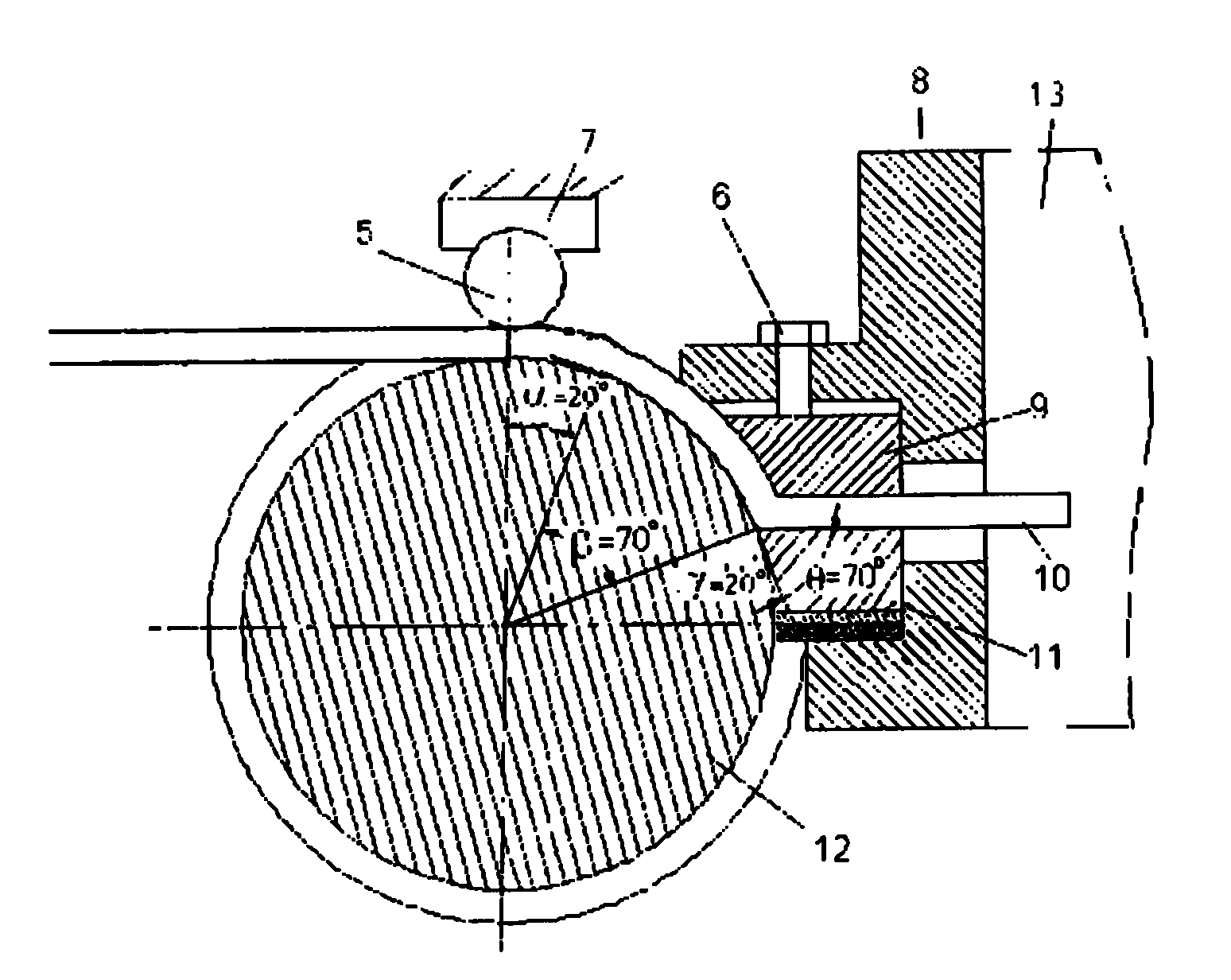

[0015] figure 1 Shown is one of the embodiments of the present invention; it is an extrusion device installed on the bar extrusion equipment to shorten the friction flow path of the billet, and it adopts the method of simultaneously adjusting the biting wheel 5 and the extrusion cavity 9 The mode of position, its structure comprises frame 13, electric extrusion wheel 12, biting wheel 5, boot seat 8 and extrusion cavity 9, it is characterized in that: on the frame 13 of its extruder, install by The billet friction flow path shortening device composed of the wrap angle adjustment mechanism and the auxiliary billet biting mechanism, the billet friction flow path shortening device is to wrap the friction flow path of the billet 10 around the extrusion wheel 12 through the wrap angle adjustment mechanism The adjustment of β and the adjustment of the rotation angle θ that the billet 10 turns to enter the extrusion cavity 9 along the tangential direction of the extrusion wheel 12; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com