Special high-performance carboxyl-terminated polyester resin for powder coating and synthesis method thereof

A carboxyl-terminated polyester and powder coating technology, applied in powder coatings, polyester coatings, epoxy resin coatings, etc., can solve the problems of high curing temperature, long baking time, long time period, etc., to ensure impact performance, The effect of shortening the gel time and improving the weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

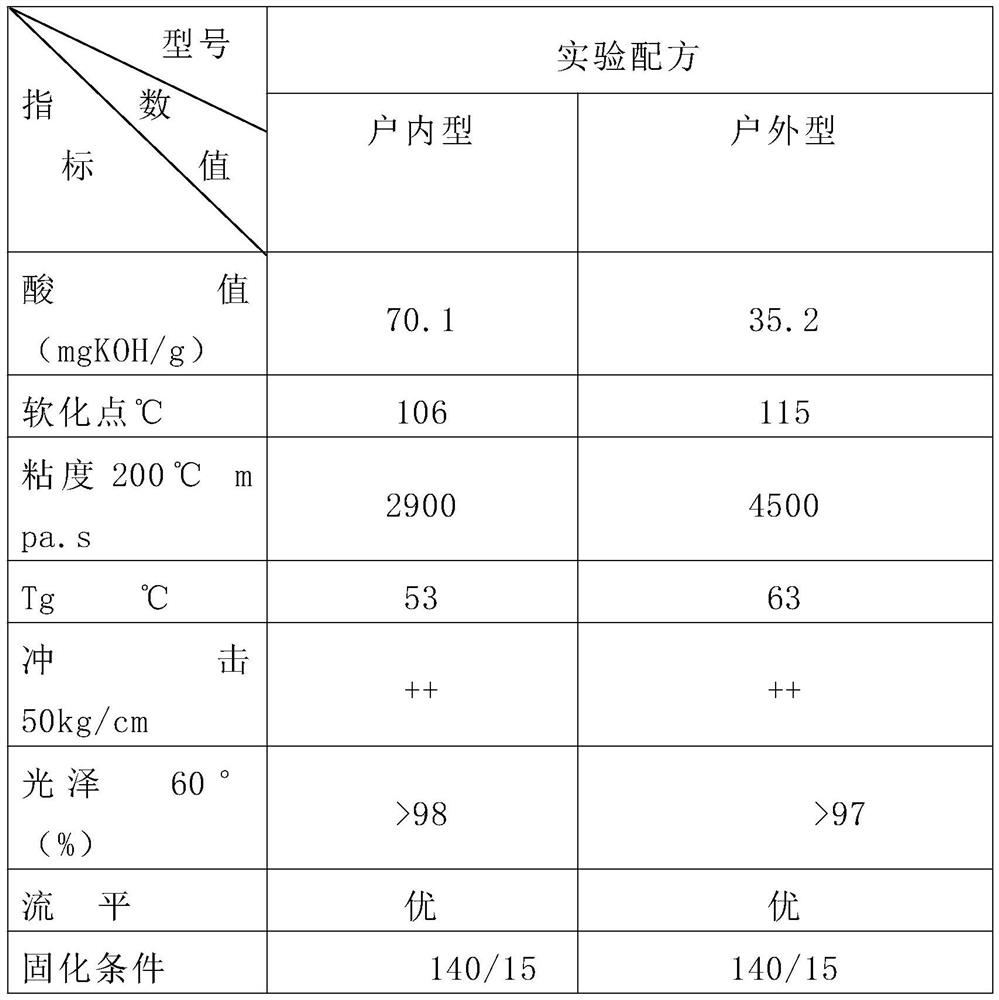

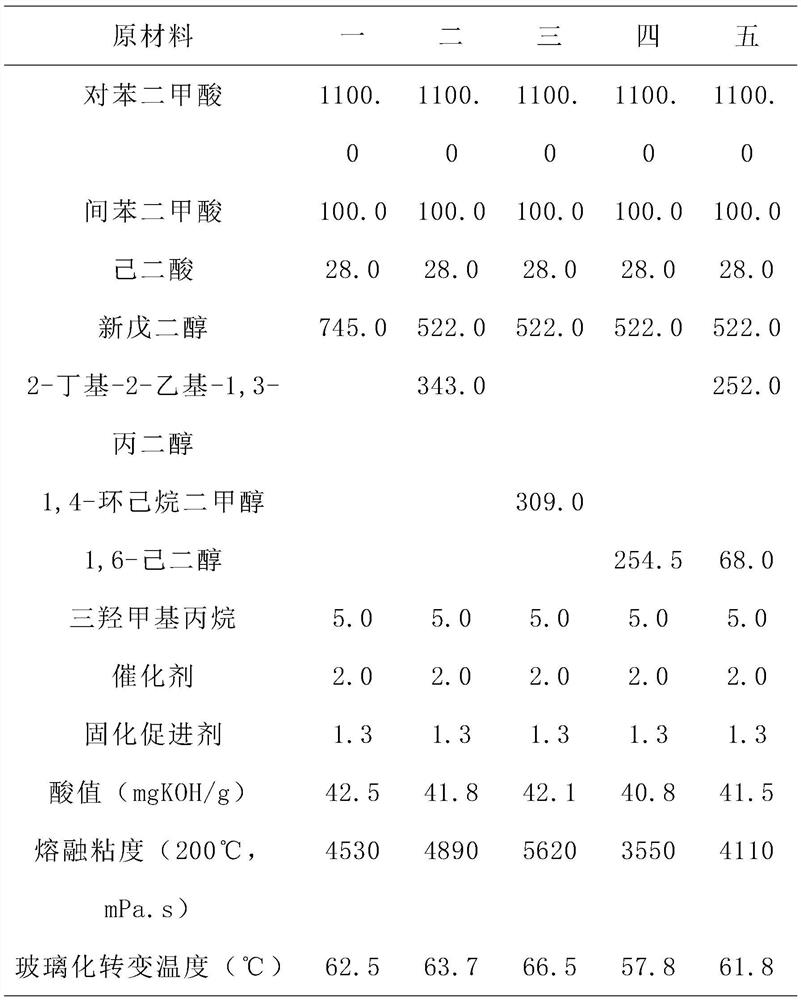

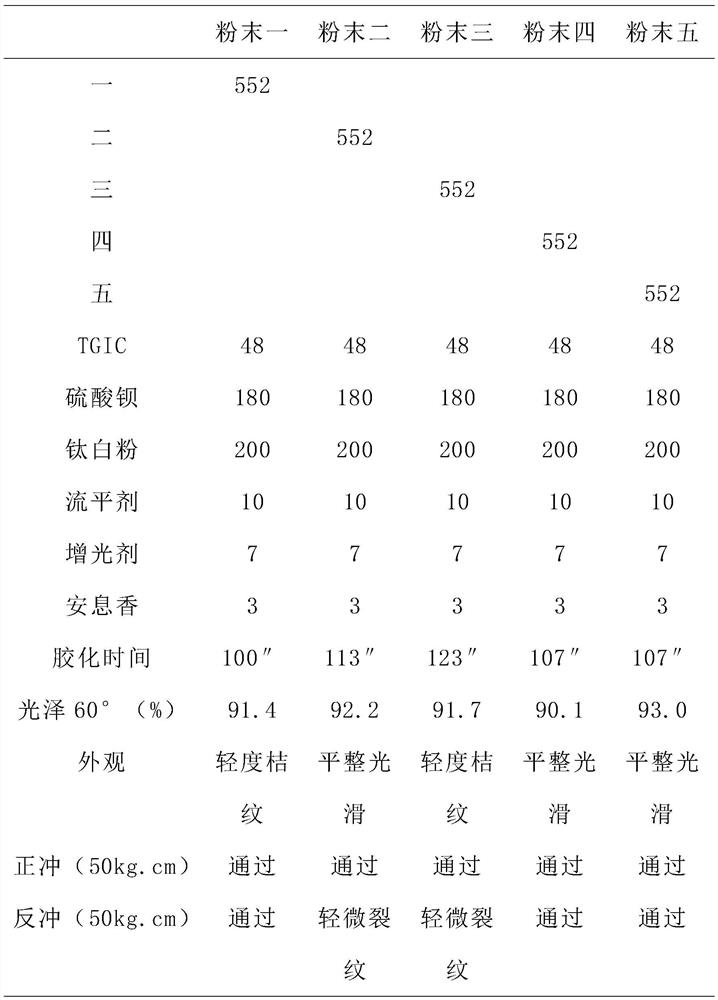

[0034] Example: A high-performance carboxyl-terminated polyester resin for powder coatings, the acid value of the indoor type is 70.7mgKOH / g, the melt viscosity is 3500mPa.s, the softening point is 106°C, the number-average molecular weight of the resin is 3209, and the weight-average The molecular weight is 5425, the molecular weight distribution is 1.53, the glass transition temperature of the resin is 53.52°C, the acid value outdoor type is 35.6mgKOH / g, the melt viscosity is 5500mPa.s, the softening point is 116°C, the number average molecular weight of the resin is 5506, and the weight The average molecular weight is 8356, the molecular weight distribution is 1.48, and the glass transition temperature of the resin is 63.46°C, which is obtained by the melting polycondensation reaction of the following raw materials in parts by weight:

[0035] Polyols include neopentyl glycol, ethylene glycol, and also 2-methyl-1,3-propanediol, 1,6-hexanediol, 1,4-cyclohexanedimethanol, 2-bu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com