Preparation method of phenolic resin base carbon aerogel

A technology of carbon airgel and phenolic resin, applied in chemical instruments and methods, colloid chemistry, colloid chemistry, etc., can solve the problems of long gel time and aging time, high raw material price, slow reaction rate, etc., and shorten aging The effect of time, low price, and shortened production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] This embodiment includes the following steps:

[0021] (1) Preparation of phenolic resin solution: Mix 100g of phenolic resin (purchased from Beijing Glass Steel Institute Composite Materials Co., Ltd., the aminophenolic resin is an ethanol solution, the original resin concentration is 68wt%) with 100g of methanol to make the phenolic resin in the solution The concentration in is 34wt%, stirs, forms transparent red solution;

[0022] (2) High temperature and high pressure gelation and aging: Pour the phenolic resin solution into a glass beaker, put the beaker into an autoclave, and add methanol equivalent to 15% of the volume of the autoclave into the autoclave (the autoclave in this embodiment The volume is 10L, the volume of methanol added is 1.5L), the mouth of the beaker is higher than the methanol liquid level in the autoclave, so that the phenolic resin solution and methanol are separated; fill nitrogen to the pressure of 2MPa to prevent the organic solvent from v...

Embodiment 2 to Embodiment 23

[0027] In embodiment 2 to embodiment 23, following each step processing parameter is listed in table 1:

[0028] (1) Types of organic solvents and resin concentrations during the preparation of phenolic resin solutions;

[0029] (2) Types of organic solvents, heating rate, holding temperature, and holding time during the high-temperature, high-pressure gelation and aging process;

[0030] (3) The drying temperature in the supercritical drying process;

[0031] (4) Protective gas and cracking temperature during cracking and carbonization.

[0032] Other processing parameters, reagent consumption are identical with embodiment 1.

[0033] The performance parameters of the carbon aerogels obtained in Examples 1 to 23 are listed in Table 2.

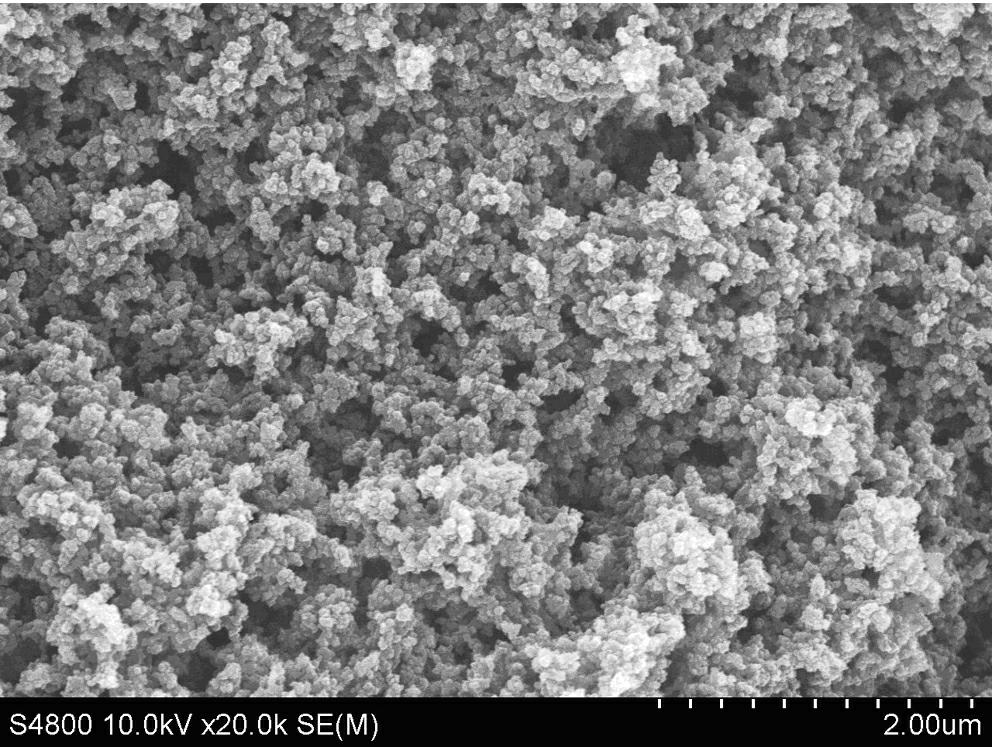

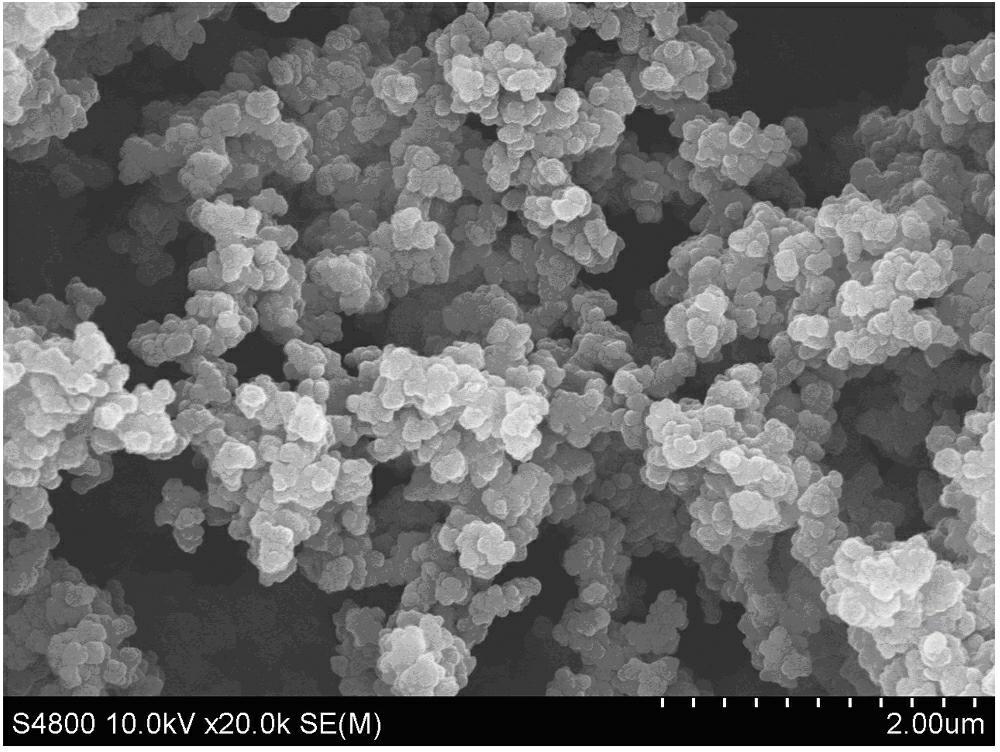

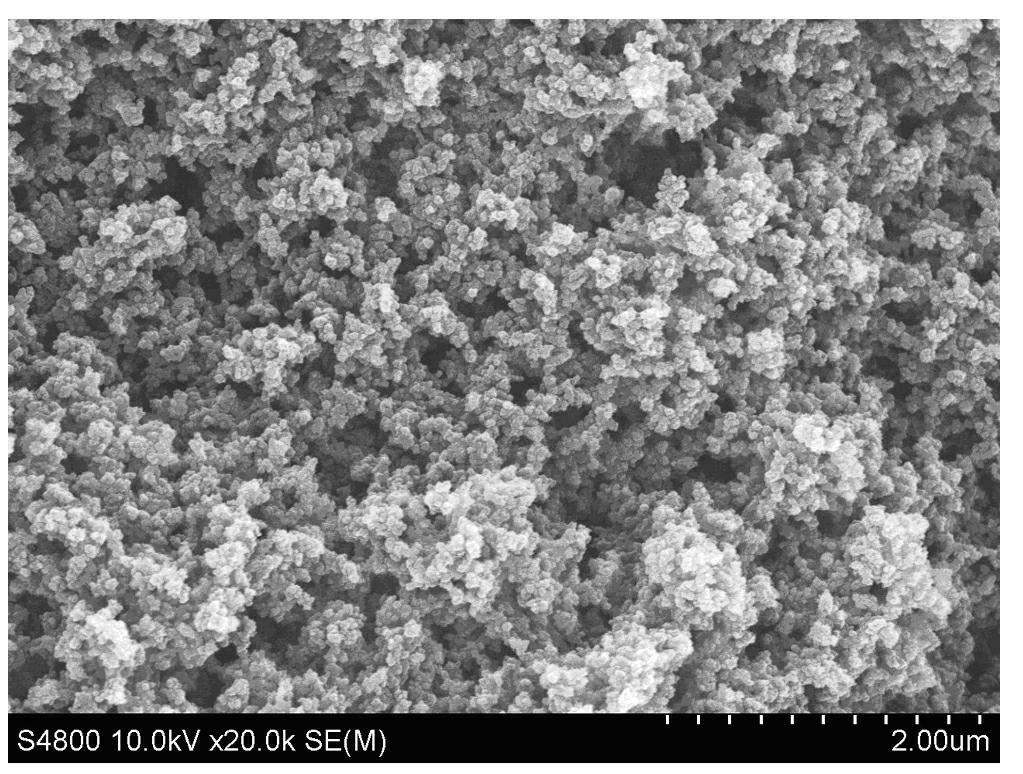

[0034] figure 2 It is a scanning electron micrograph of the carbon airgel obtained in Example 21. It can be seen from the figure that the particle size of the carbon airgel in Example 21 is relatively large, in the range of 50-150 nm. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com