Nanometer modified rapid prototyping polymer insulating material and preparation method thereof

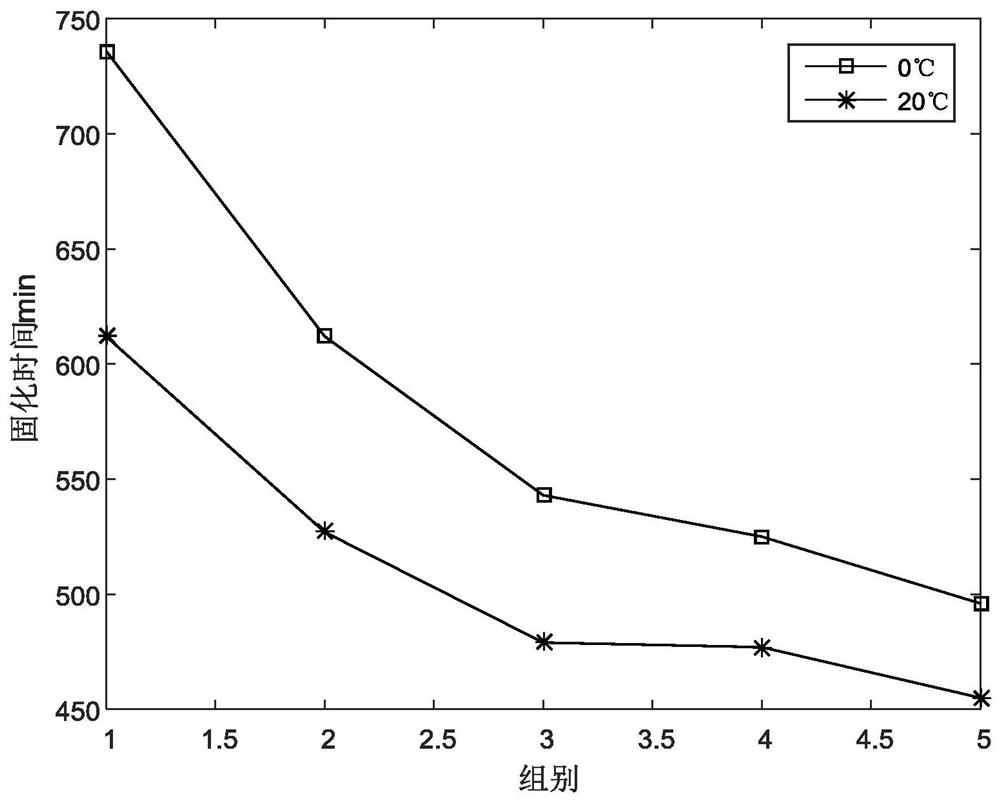

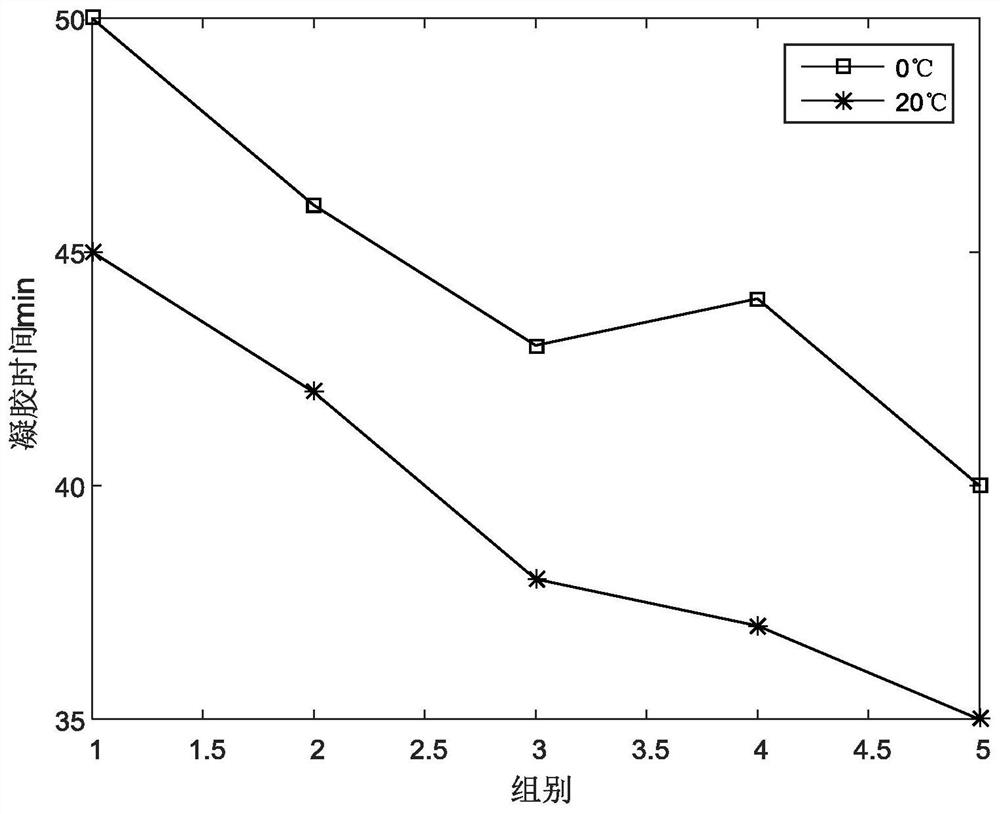

A nano-modified and insulating material technology, applied in coatings and other directions, can solve the problems of high cost of insulated wires, unsatisfactory thermal conductivity and aging resistance, and inability to operate in winter, so as to improve thermal conductivity and aging resistance. The effect of improving gel conditions and curing conditions, shortening gel time and curing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

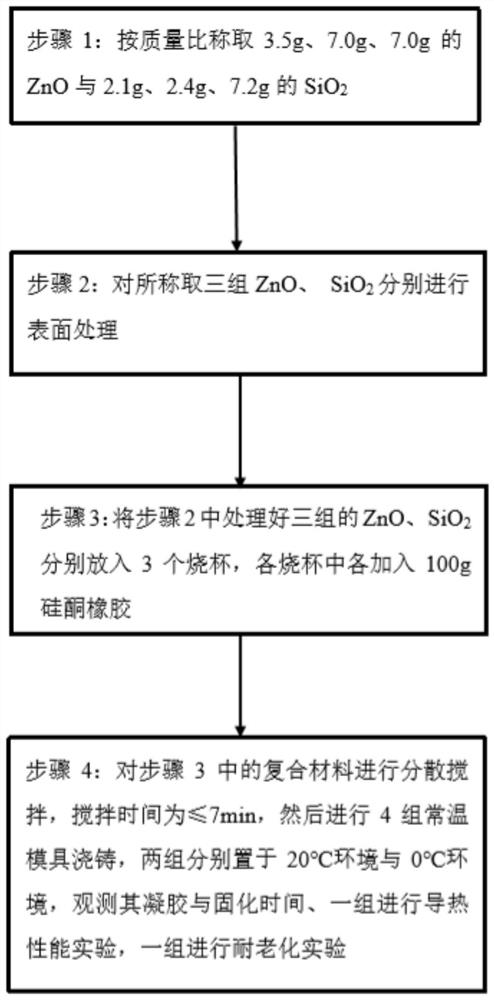

[0048] A method for preparing a nano-modified rapid prototyping polymer insulating material, specifically implemented according to the following steps:

[0049] Step 1, take by weight 3.5g nano-zinc oxide, 2.1g nano-silicon dioxide; Nano-zinc oxide particle diameter is 70nm; Powder particle diameter is the nano-silicon dioxide of 70nm;

[0050] Step 2, surface treatment is carried out to the nano-zinc oxide and nano-silicon dioxide weighed in step 1:

[0051] Step 2.1, put the weighed ZnO powder in a beaker, add 400% by mass absolute ethanol to fully dilute, mechanically and ultrasonically stir evenly (time ≥ 20min, speed 225r / min);

[0052] Step 2.2, prepare KH550 solution, weigh KH550 with 10% weight of ZnO powder and place it in a small beaker, add purified water half of the mass of KH550, then add absolute ethanol 3.5 times the mass of KH550, mix well and set aside;

[0053] Step 2.3, after step 2.1 is stirred, add the solution prepared in step 2.2, mechanically and ultra...

Embodiment 2

[0066] A method for preparing a nano-modified rapid prototyping polymer insulating material, specifically implemented according to the following steps:

[0067] Step 1, take by weight 7.0g nano-zinc oxide, 2.4g nano-silicon dioxide, the powder particle diameter is the nano-silicon dioxide of 50nm, the nano-zinc oxide particle diameter is 50nm;

[0068] Step 2, surface treatment is carried out to the nano-zinc oxide and nano-silicon dioxide weighed in step 1:

[0069] Step 2.1, put the weighed ZnO powder in a beaker, add 400% by mass absolute ethanol to fully dilute, mechanically and ultrasonically stir evenly (time ≥ 20min, speed 225r / min);

[0070] Step 2.2, prepare KH550 solution, weigh KH550 with 10% weight of ZnO powder and place it in a small beaker, add purified water half of the mass of KH550, then add absolute ethanol 3.5 times the mass of KH550, mix well and set aside;

[0071] Step 2.3, after step 2.1 is stirred, add the solution prepared in step 2.2, mechanically a...

Embodiment 3

[0081] A method for preparing a nano-modified rapid prototyping polymer insulating material, specifically implemented according to the following steps:

[0082] Step 1, take by weight 7g nano-zinc oxide, 7.2g nano-silicon dioxide; The nano-zinc oxide particle diameter is 40nm, and the powder particle diameter is the nano-silicon dioxide of 40nm;

[0083] Step 2, surface treatment is carried out to the nano-zinc oxide and nano-silicon dioxide weighed in step 1:

[0084] Step 2.1, put the weighed ZnO powder in a beaker, add 400% by mass absolute ethanol to fully dilute, mechanically and ultrasonically stir evenly (time ≥ 20min, speed 225r / min);

[0085] Step 2.2, prepare KH550 solution, weigh KH550 with 10% weight of ZnO powder and place it in a small beaker, add purified water half of the mass of KH550, then add absolute ethanol 3.5 times the mass of KH550, mix well and set aside;

[0086] Step 2.3, after step 2.1 is stirred, add the solution prepared in step 2.2, mechanically...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com