Modified phenol formaldehyde resin, backing plate and preparation method thereof

A phenolic resin and modification technology, which is applied in chemical instruments and methods, synthetic resin layered products, and other household appliances, can solve the problems of inability to drill holes with small apertures, large holes, and low drilling accuracy. Solve the high rate of broken needles in drilling, improve production efficiency, and improve the effect of hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

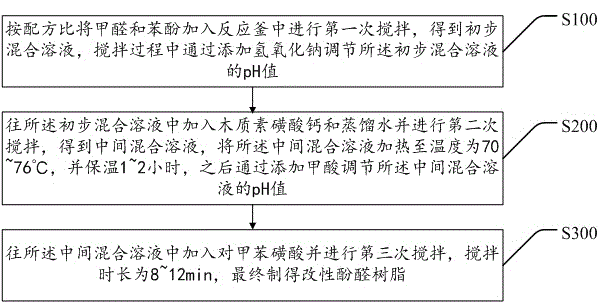

[0052] 1. Preparation of modified phenolic resin:

[0053] a. According to the formula ratio, add 28% formaldehyde and 25% phenol into the reactor for the first stirring to obtain a preliminary mixed solution. The first stirring speed is 50 r / min, and the temperature of the preliminary mixed solution during stirring is 15 ℃, during the stirring process, the pH value of the preliminary mixed solution was adjusted to 8.0 by adding 1.8% sodium hydroxide; after adjusting the pH value of the preliminary mixed solution, the air pressure was 1 kg / cm 2 The gas is used to heat up the preliminary mixed solution to 53° C. within 30 minutes;

[0054] b. Add 15% calcium lignosulfonate and 20% distilled water to the preliminary mixed solution and stir for the second time to obtain an intermediate mixed solution. The second stirring speed is 50 r / min, and the intermediate The mixed solution was heated to a temperature of 70° C. and kept for 1 hour, and then the pH value of the intermediat...

Embodiment 2

[0061] 1. Preparation of modified phenolic resin:

[0062] a. According to the formula ratio, add 30% formaldehyde and 27% phenol into the reactor for the first stirring to obtain a preliminary mixed solution. The first stirring speed is 75 r / min, and the temperature of the preliminary mixed solution during stirring is 20 ℃, during the stirring process, the pH value of the preliminary mixed solution was adjusted to 8.0 by adding 2.0% sodium hydroxide; after adjusting the pH value of the preliminary mixed solution, the air pressure was 1.2 kg / cm 2 The gas is used to heat up the preliminary mixed solution to 55°C within 30 minutes;

[0063] b. Add 17% calcium lignosulfonate and 23% distilled water to the preliminary mixed solution and stir for the second time to obtain an intermediate mixed solution. The second stirring speed is 60 r / min, and the intermediate The mixed solution was heated to a temperature of 74° C. and kept for 1.5 hours, and then the pH value of the intermed...

Embodiment 3

[0070] 1. Preparation of modified phenolic resin:

[0071] a. According to the formula ratio, add 32% formaldehyde and 29% phenol into the reactor for the first stirring to obtain a preliminary mixed solution. The first stirring speed is 100 r / min, and the temperature of the preliminary mixed solution during stirring is 25 ℃, during the stirring process, the pH value of the preliminary mixed solution was adjusted to 8.0 by adding 2.2% sodium hydroxide; after adjusting the pH value of the preliminary mixed solution, the air pressure was 1.5 kg / cm 2 The gas is used to heat up the preliminary mixed solution to 57°C within 30min;

[0072] b. Add 19% calcium lignosulfonate and 26% distilled water to the preliminary mixed solution and stir for the second time to obtain an intermediate mixed solution. The second stirring speed is 70 r / min, and the intermediate The mixed solution was heated to a temperature of 76° C. and kept for 2 hours, and then the pH value of the intermediate m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com