Method for testing chemical stability of latex and application of method

A chemical stability and testing method technology, applied in the direction of measuring devices, scientific instruments, instruments, etc., can solve problems such as glue blocking, affecting product quality and cost, gel, etc., to ensure accuracy, prolong heating and stirring time, increase Judging the effect of the difficulty of the gel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

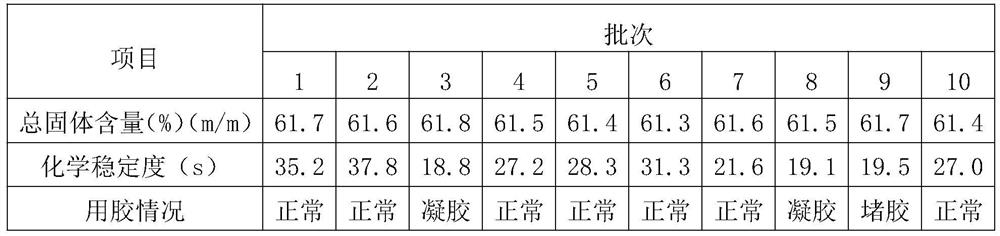

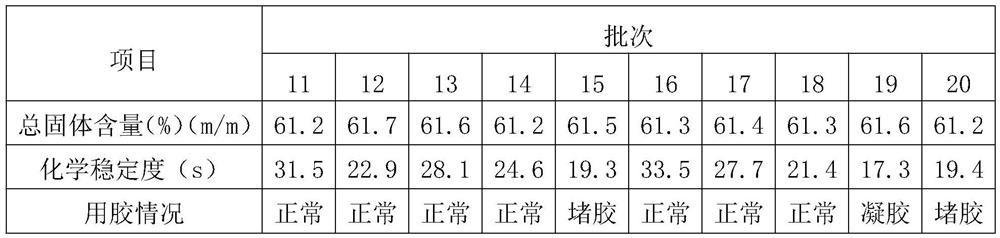

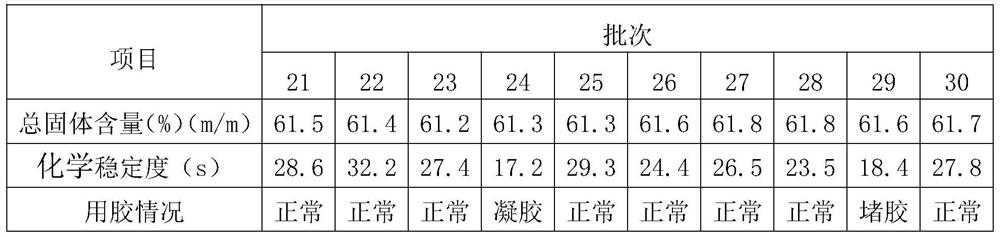

[0026] Example 1. A kind of test method of latex chemical stability, test method is: at 25 ℃ of temperature, under the laboratory environment of relative humidity 75, accurately take by weighing concentration respectively with the beaker of 250mL that concentration is 30% ammonium sulfate (analytical grade) solution 50g and Total alkalinity is 0.70%, total solid content 61.5%, the latex 50g that filters through 60 order stainless steel screens, the method for the ammonium sulfate solution after weighing and latex temperature water bath is adjusted to 25 ℃ respectively. Add the ammonium sulfate solution to the latex, stir with a glass rod at a speed of 3 rpm for 3 seconds, then quickly transfer the beaker containing the latex to an electric heating constant temperature magnetic stirring water bath set at 75°C, and continue stirring , the stirring frequency is 180 rev / min (the constant temperature water surface height is about 1.5 times of the latex liquid level height in the be...

Embodiment 2

[0029] Example 2. A kind of test method of latex chemical stability, test method is: under 24 ℃ of temperature, under the laboratory environment of relative humidity 73.5, be that the ammonium sulfate (analytical grade) solution 49.99g of 30% is accurately weighed respectively with the beaker of 250mL concentration And total alkalinity is 0.70 ± 0.02%, total solid content 61.5 ± 0.3%, latex 49.99g filtered through 60 mesh stainless steel wire mesh, the method for the ammonium sulfate solution after weighing and latex temperature is adjusted to 25 ℃ with water bath . Add the ammonium sulfate solution into the latex, stir with a glass rod at a speed of 3 revolutions per second for 3 seconds, then quickly transfer the beaker containing the latex to an electric heating constant temperature magnetic stirring water bath set at 70°C, and continue stirring , the stirring frequency is 160 rev / min (the height of the constant temperature water surface is about 1.5 times of the latex liq...

Embodiment 3

[0032] Example 3. A kind of test method of latex chemical stability, test method is: under 26 ℃ of temperature, under the laboratory environment of relative humidity 76.5, be that the ammonium sulfate (analytical grade) solution 50.01g of 30% is accurately taken by weighing concentration respectively with the beaker of 250mL And the total alkalinity is 0.70 ± 0.02%, the total solid content is 61.5 ± 0.3%, and the latex 50.01g filtered through 60 mesh stainless steel wire mesh is adjusted to 25 ℃ by the method of water bath of ammonium sulfate solution after weighing and latex temperature . Add the ammonium sulfate solution into the latex, stir with a glass rod at a speed of 3 revolutions per second for 3 seconds, then quickly transfer the beaker containing the latex to an electric heating constant temperature magnetic stirring water bath set at 80°C, and continue stirring , the stirring frequency is 200 rev / min (the constant temperature water surface height is about 1.5 times...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com