A kind of ultrasonic metallurgy device used in rh refining furnace

A technology of ultrasonic and refining furnace, which is applied in the field of refining metallurgy to achieve the effect of improving the circulation efficiency of molten steel and improving degassing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

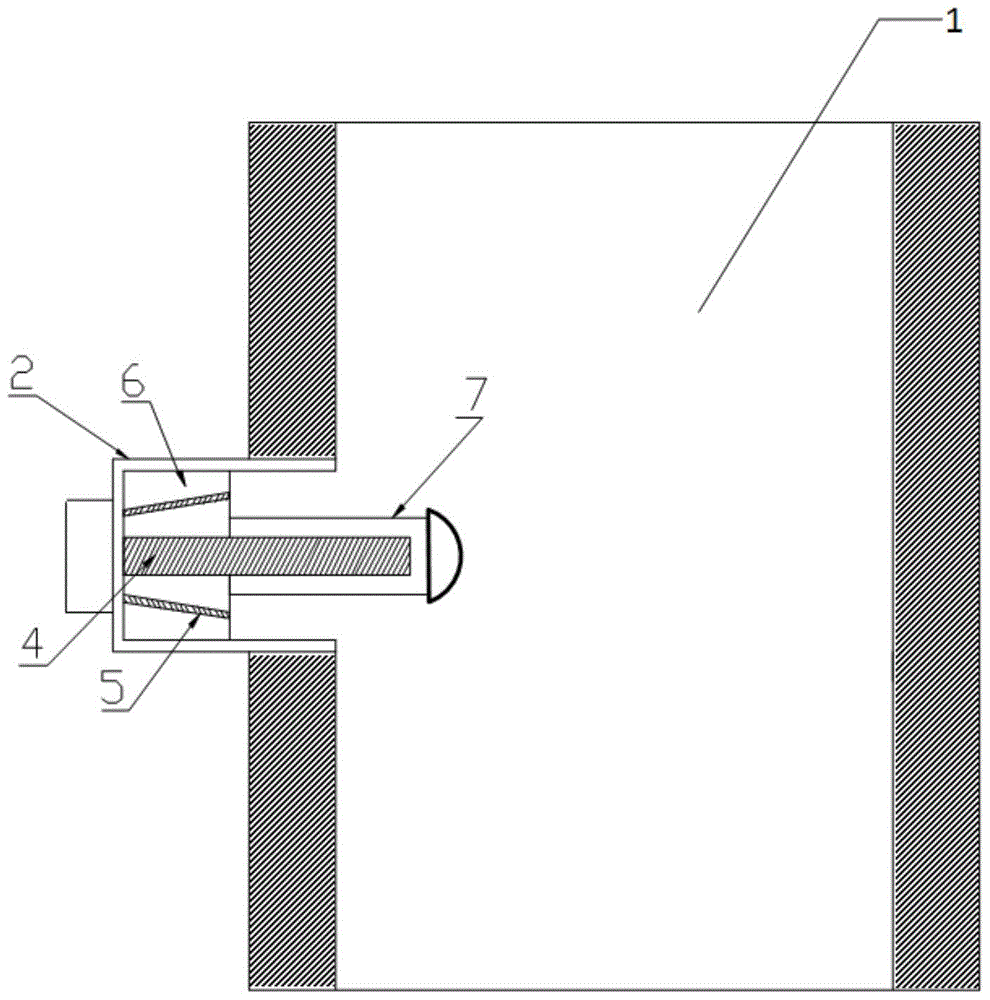

[0024] like figure 1 and figure 2 Shown, a kind of ultrasonic metallurgical device for RH refining furnace, described device comprises the outer frame 2 that is connected with RH refining furnace riser 1, and described outer frame 2 is provided with ultrasonic generator 6 and is used for ultrasonic generator The ultrasonic wave generated by 6 is input to the ultrasonic working head 7 in the riser 1; the outer frame 2 is also provided with an argon blowing pipe 4 communicating with the riser 1 and six argon seals surrounding the argon blowing pipe 4 for air sealing. Tube 5; the argon blowing tube 4 and six argon sealing tubes 5 pass through the outer frame 2 and are connected to the argon gas source.

[0025] One end of the argon blowing pipe 4 extending into the riser 1 is in the shape of a shower head.

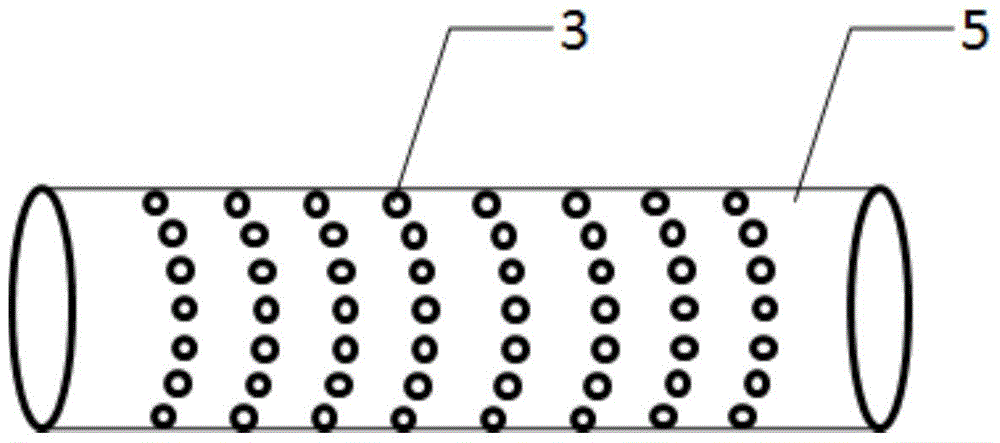

[0026] Eight circles of through holes 3 are provided in a circular shape on the outer surface of the argon-sealed tube 5 .

[0027] The ultrasonic generator 6 is arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com