RH bottom blowing argon vacuum circulating degasser

A technology of vacuum cycle degassing and bottom blowing argon, applied in the field of metallurgy, can solve the problem that the diameter of the rising pipe cannot be infinite, and achieve the effect of shortening the mixing time, speeding up the removal, and improving the degassing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

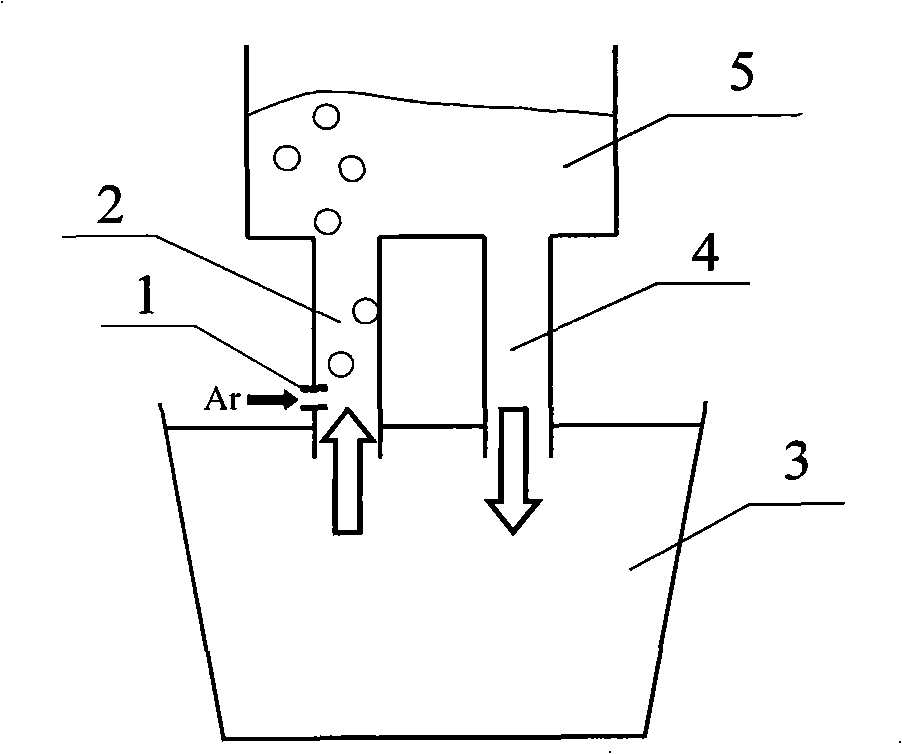

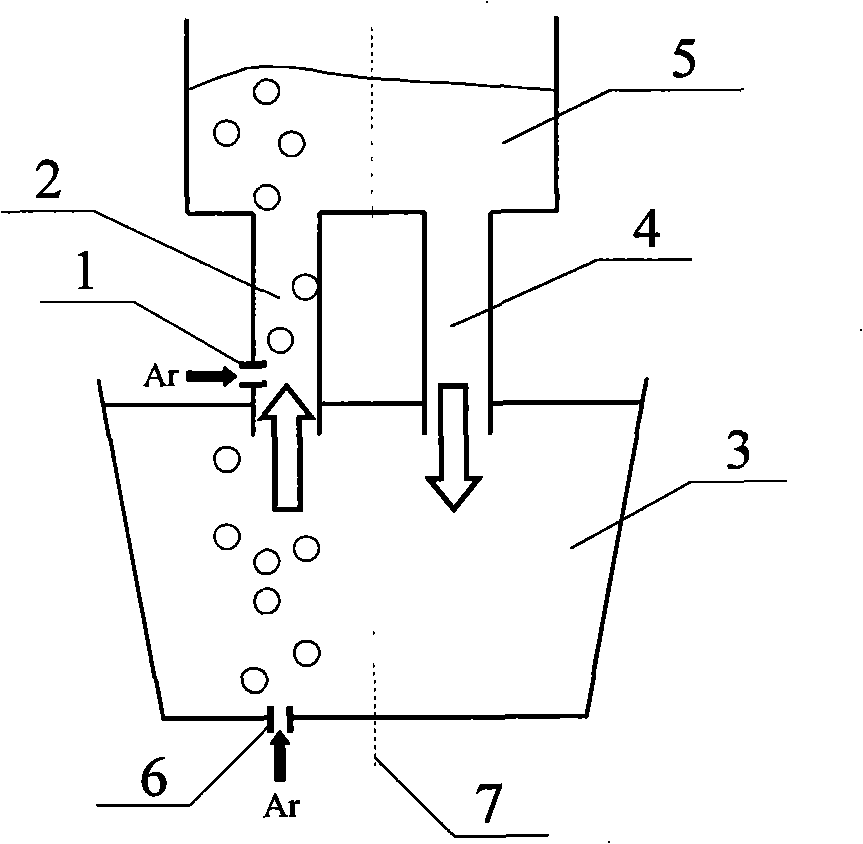

[0023] The structure of the RH bottom blowing argon vacuum cycle degassing device is as follows: figure 2 As shown, it includes a ladle 3 and a vacuum chamber 5 , the bottom of the vacuum chamber 5 is provided with an ascending pipe 2 and a descending pipe 4 , and the ascending pipe 2 is connected to the side argon blowing device 1 . Wherein, the bottom wall of the ladle 3 is provided with a nozzle 6, and the nozzle 6 is connected with an argon blowing device at the bottom. The straight line passing through the center of the bottom wall of the ladle and parallel to the centerline of the riser and the centerline of the downcomer is the centerline 7 of the ladle.

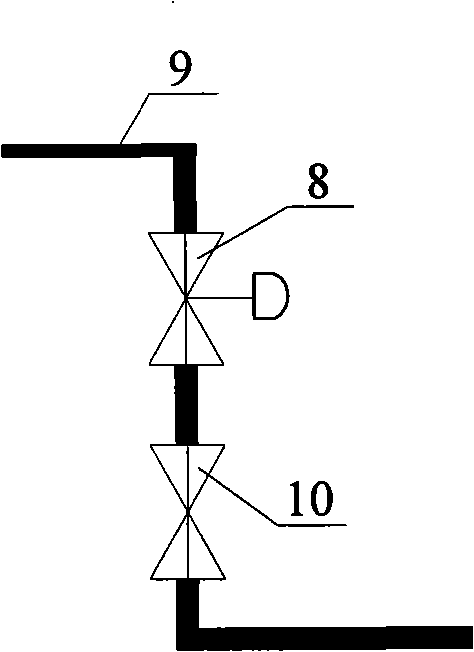

[0024] Argon blowing device at the bottom of the ladle such as image 3 shown. The bottom argon blowing device includes a regulating valve 8 , an argon blowing pipe 9 and a shut-off valve 10 . The nozzle 6 communicates with the argon blowing pipe 9 , and the argon blowing pipe 9 is provided with a shut-off valve 1...

Embodiment 2

[0034] The structure of the RH bottom blowing argon vacuum cycle degassing device is as follows: Figure 4 As shown, the bottom wall of the ladle 3 is provided with a ventilating brick 11, and the ventilating brick 6 is connected with an argon blowing device, and the other parts are the same as in the first embodiment.

[0035] Argon blowing device at the bottom of the ladle such as image 3 shown. The bottom argon blowing device includes a regulating valve 8 , an argon blowing pipe 9 and a shut-off valve 10 . The ventilation brick 6 communicates with the argon blowing pipe 9, and the argon blowing pipe 9 is provided with a shut-off valve 10 and a regulating valve 8.

[0036] The bottom wall of the ladle is provided with a breathable brick 11, and the breathable brick 11 is connected to the bottom argon blowing device; the breathable brick 11 is located on the side where the rising pipe 2 projects on the bottom wall of the steel ladle 3, that is, the left side of the center ...

Embodiment 3

[0042] The RH bottom blowing argon vacuum circulation degassing device is the same as that of Example 1, the difference is that: the bottom wall of the ladle is provided with two nozzles, and the inner diameter of the gas outlet of the nozzles is 5mm; each nozzle is connected to a bottom argon blowing device; two nozzles It is located on the side of the projection of the riser on the bottom wall of the ladle, that is, on the left side of the center line 7 of the ladle; the centers of the inner holes of the two nozzles and the center of the bottom wall are on the same straight line.

[0043] The size and structure of the RH bottom blowing argon vacuum circulation degassing device are as follows: Image 6 shown, where S no1 is the distance from the argon blowing position at the bottom of the first ladle (the center of the position where the nozzle is located) to the center of the ladle, and S no1 =535mm; S no2 is the distance from the argon blowing position at the bottom of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com