Preparation equipment and method of modified polyurethane material

A polyurethane material and modification technology, applied in the field of polyurethane materials, can solve the problems of complex equipment structure, inconvenient use, etc., and achieve the effect of accelerating dehydration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

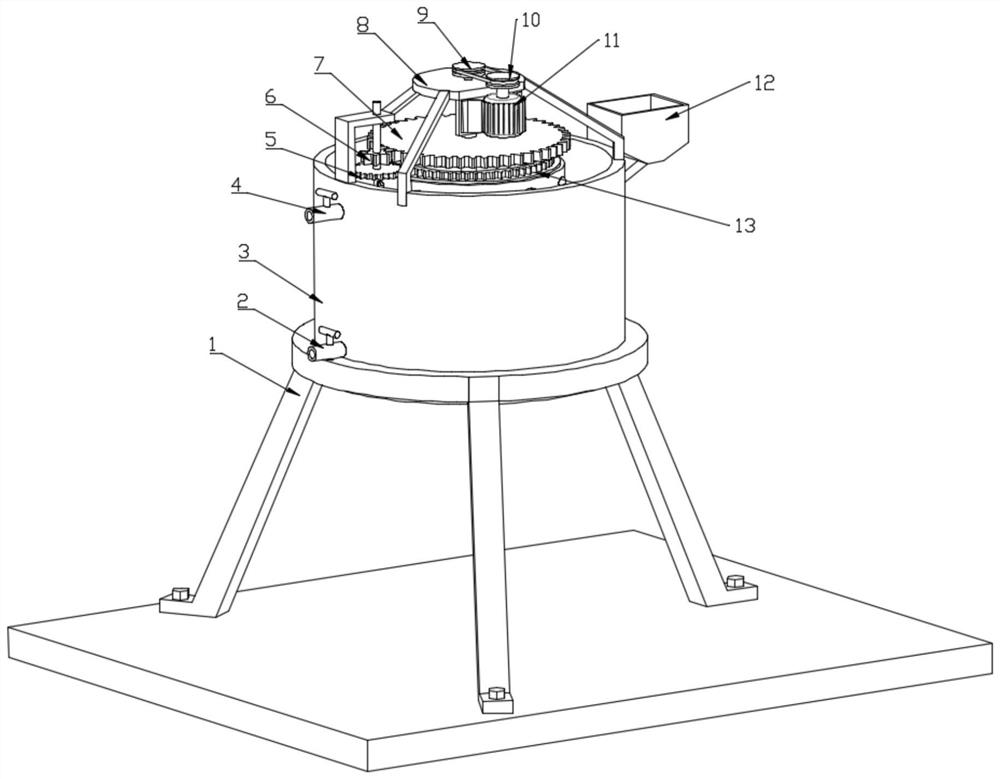

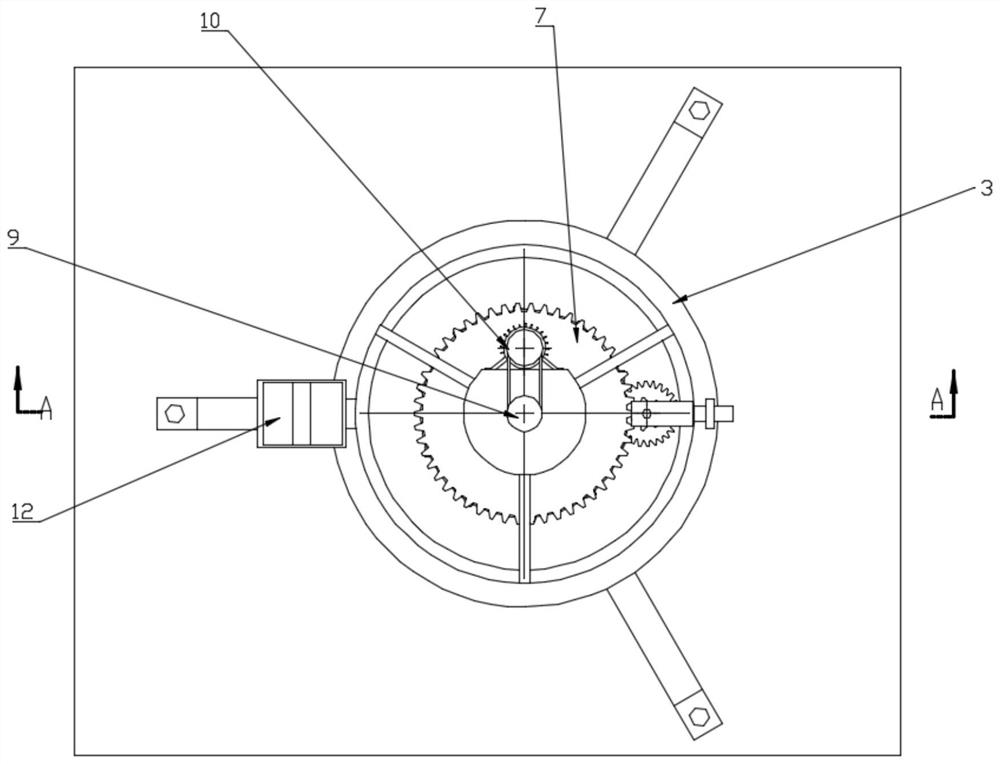

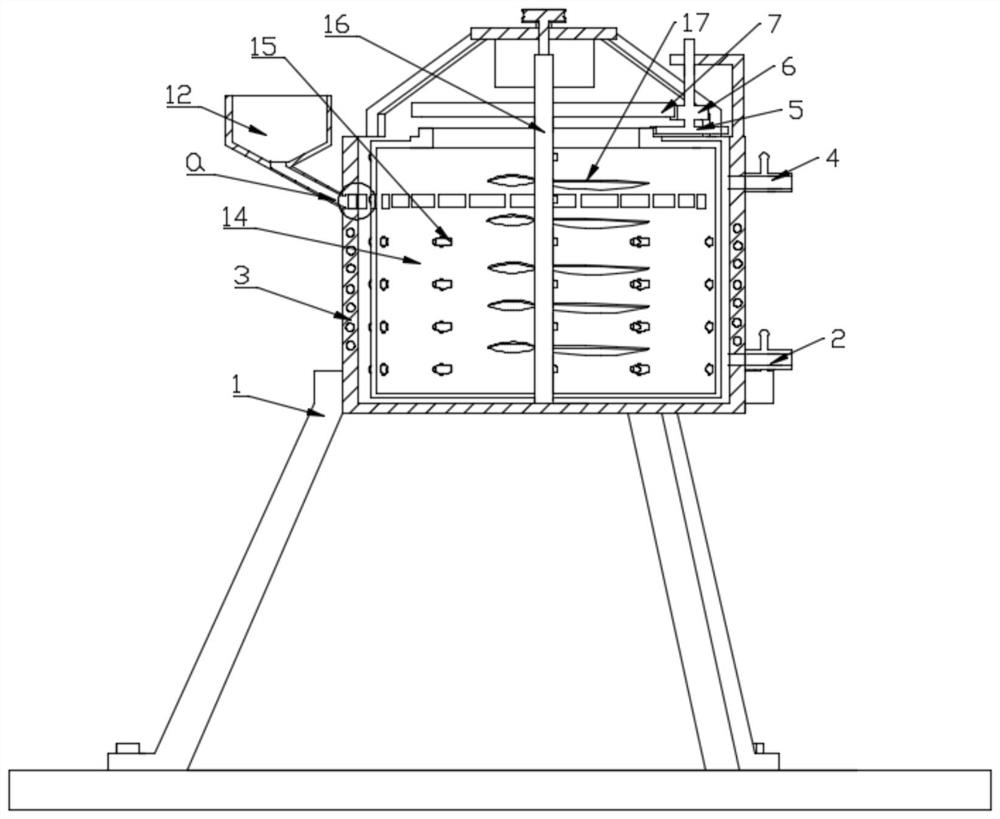

[0044] refer to Figure 1 ~ Figure 3 , In this embodiment, a preparation device for modified polyurethane material is proposed, and the preparation device for modified polyurethane material includes: an outer cylinder 3, an inner barrel 14 and a driving member.

[0045] The outer cylinder 3 may have a barrel-shaped structure, and the outer cylinder 3 may be made of stainless steel, so as to ensure a certain rigidity and avoid deformation of the outer cylinder 3 during operation. The bottom of the outer cylinder 3 can be provided with a support frame 1, the bottom of the support frame 1 is fixedly provided with a backing plate, the backing plate is provided with a through hole, and the bolt passes through the through hole to fix the outer tube 3. Of course, the bottom of the support frame 1 can also be provided with one or a combination of rotating wheels and universal wheels, and the rotating wheels and / or universal wheels are provided with clamps for braking, so as to facilit...

Embodiment 2

[0057] refer to Image 6 , the inside of the through hole 15 can be provided with a screen 21, the screen 21 has a filtering effect, thereby facilitating the separation of solids and liquids, of course, it can also be directly filtered through the through hole 15, but the processing is difficult and the cleaning is inconvenient. The outer wall of the embedded barrel 14 is fixedly connected with several arc rings 22, the arc rings 22 correspond to the through holes 15 and are arranged on the reverse rotation side of the tangent, the setting of the arc rings 22 can make the embedded barrel 14 forward When rotating, the liquid can be well entered into the inside of the built-in bucket 14, and when reversely rotated, the liquid can be prevented from entering the inside of the built-in bucket 14, and the dehydration can be well completed.

Embodiment 3

[0059] refer to Figure 7 , a preparation method of a modified polyurethane material is proposed in this embodiment, comprising the following steps:

[0060] S1. The first raw material is added into the inner barrel 14 and the outer barrel 3 .

[0061] S2. The driving part drives the rotating shaft 16 and the embedded barrel 14 to rotate forward, the embedded barrel 14 rotates to make the liquid enter the inner barrel 14 through the through hole 15, and the fan blade 17 rotates to make the liquid inside the embedded barrel 14 upward send.

[0062] S3. The heating element heats the reactants inside the outer cylinder 3 to a preset temperature.

[0063] S4. The reaction solution reacts for a preset time period.

[0064] S5. The controller controls the driving part to drive the rotating shaft 16 and the embedded barrel 14 to rotate in reverse, so that the fan blade 17 rotates and squeezes downward for dehydration.

[0065] S6. The driving part drives the rotating shaft 16 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com