A kind of coated paper applied to food packaging and production process of the paper

A food packaging and production technology technology, applied in the field of coated paper, can solve the problems of poor bonding ability between the film layer and the substrate layer of the coated paper, unable to ensure uniform dispersion of raw materials, unable to meet the requirements of use, etc., and to accelerate the upward movement. Speed, ease of removal, improved binding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

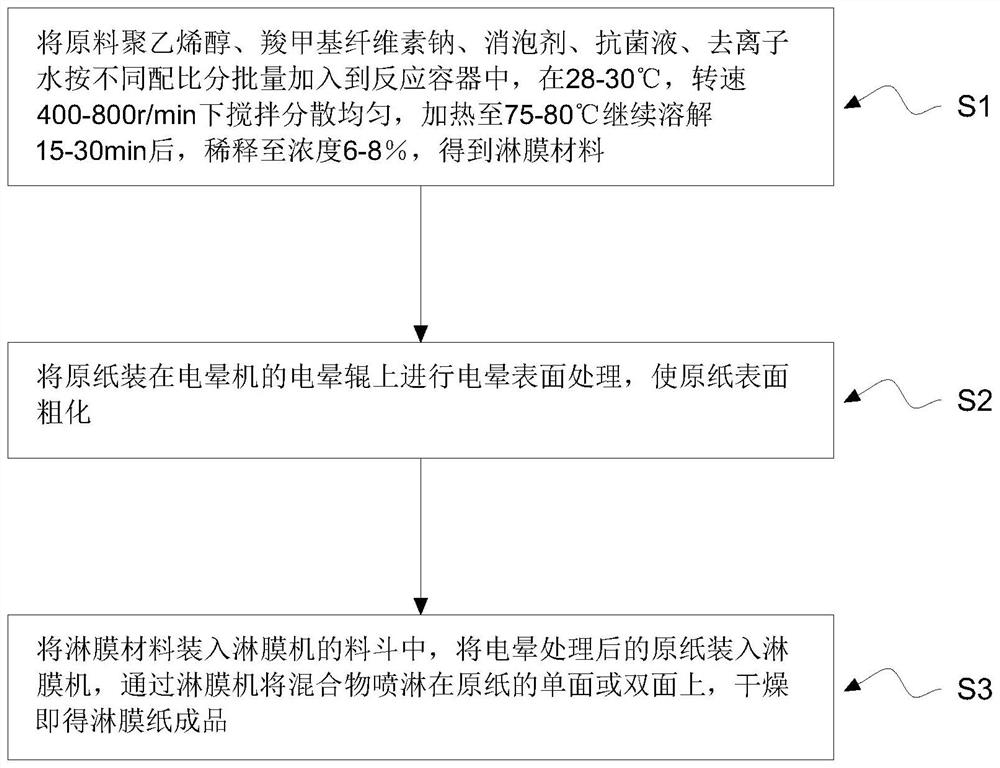

[0044] see Figure 1-7 A production process of coated paper applied to food packaging, which comprises the following steps:

[0045] S1. Add the raw materials polyvinyl alcohol, sodium carboxymethyl cellulose, defoaming agent, antibacterial liquid, and deionized water into the reaction vessel 1 in batches according to different proportions, at 28-30 ° C, and the rotating speed is 400-800 r / min. Stir and disperse evenly, heat to 75-80°C and continue to dissolve for 15-30min, then dilute to a concentration of 6-8% to obtain a coating material;

[0046] S2. Mount the base paper on the corona roller of the corona machine for corona surface treatment to roughen the surface of the base paper; it can increase the surface tension of the base paper, and then make the coating material better bond to the treated base paper surface;

[0047] S3. Load the laminating material into the hopper of the laminating machine, put the corona-treated base paper into the laminating machine, and spray...

Embodiment 2

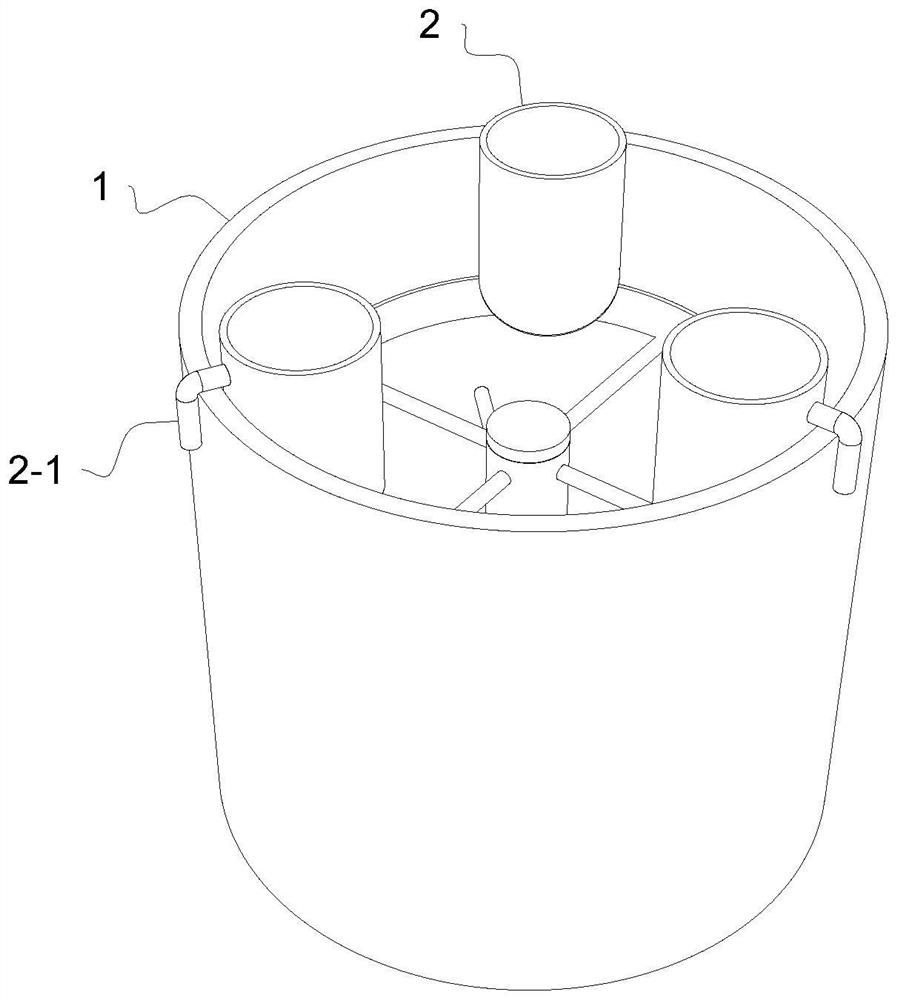

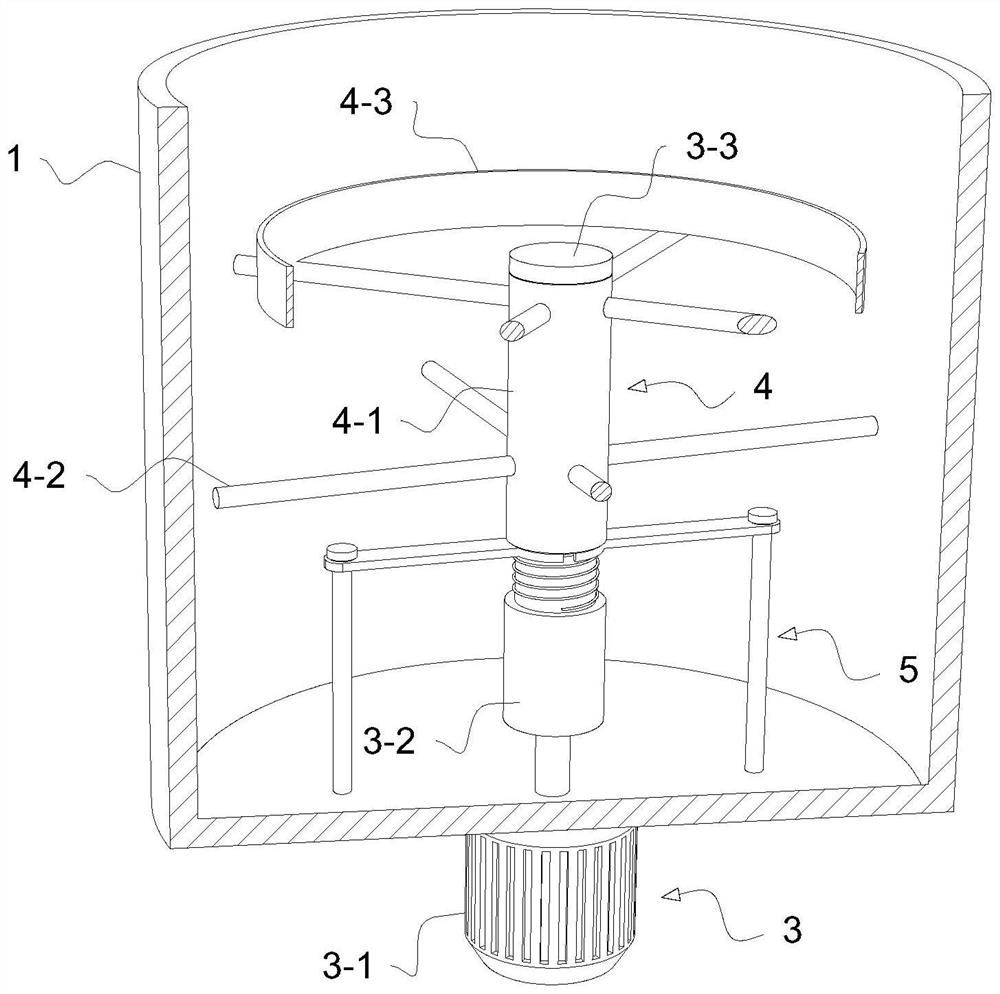

[0060] The side end surface of the material box 2 is fixedly connected with a hanging lug 2-1. The material box 2 is suspended at the upper edge of the reaction container 1 through the hanging lug 2-1 to realize a detachable connection with the reaction container 1. The material box 2 is connected to the inner wall of the reaction container 1. Fittingly, through the use of the hanging lugs 2-1, on the one hand, it is convenient to place the material box 2 at any position on the reaction vessel 1, and it is not necessary to find a specific position for installation, and it is easy to remove, on the other hand, it is convenient to use according to the needs of use. (When the reaction container 1 is applied to other material mixing environments) a plurality of material boxes 2 are arranged, and the easy disassembly operation mode between the material box 2 and the reaction container 1 facilitates the removal of the adjustment structure 4 for cleaning operations.

Embodiment 3

[0062] The bottom end of the material box 2 is set as an inclined structure, and the inclination direction is inclined downward relative to the inner wall of the reaction container 1. The difference between Example 3 and Example 2 is that the shape of the bottom end of the material box 2 is different, and the inclined setting of the material box 2 can not only The unloading of raw materials is convenient, and the surface of the hanging lugs 2-1 located in the material box 2 is less likely to have residual raw materials, and at the same time, the cleaning operation of the material box 2 is convenient.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com