Graphene production raw material mixing device

A mixing device and graphene technology, applied in the directions of mixers, mixing methods, mixed material pretreatment, etc., can solve problems such as poor mixing efficiency and uneven mixing of raw materials, so as to improve efficiency, improve convenience and speed of cleaning, and improve uniformity. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

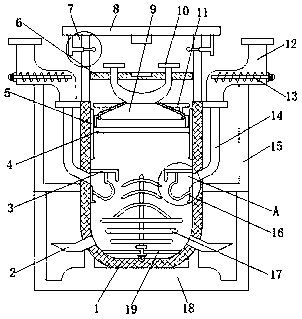

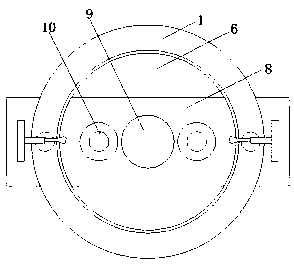

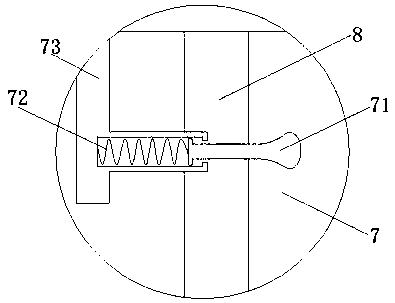

[0026] Example: refer to Figure 1-4 , a mixing device for graphene production raw materials, when graphene production is started, the raw materials for graphene production need to be fully mixed, before the various raw materials start to mix, the cover plate 6 is placed on the upper end of the mixing chamber 1 , so that the mixing chamber 1 is in a sealed state, then the liquid material to be mixed can be injected into the mixing chamber 1 through the liquid inlet pipe 10 at the upper end of the cover plate 6, and when the liquid is injected into the mixing chamber 1 through the liquid inlet pipe 10, first It needs to pass through the liquid outlet channel 9, and then fall on the upper end of the filter screen 4. Under the action of the evenly distributed through holes on the filter screen 4, the liquid falling on the filter screen 4 can be evenly distributed, so that the liquid can be evenly sprinkled. In the mixing chamber 1, the uniformity of mixing and distribution of liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com