Wool dry cleaning and bleaching liquid medicine

A technology of dry cleaning liquid and bleaching liquid, which is applied in the field of wool dry cleaning and bleaching liquid, which can solve the problems of large water consumption, low wool whiteness, and wool damage, etc., to improve the cleaning degree, enhance mixing and dissolution, and reduce costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

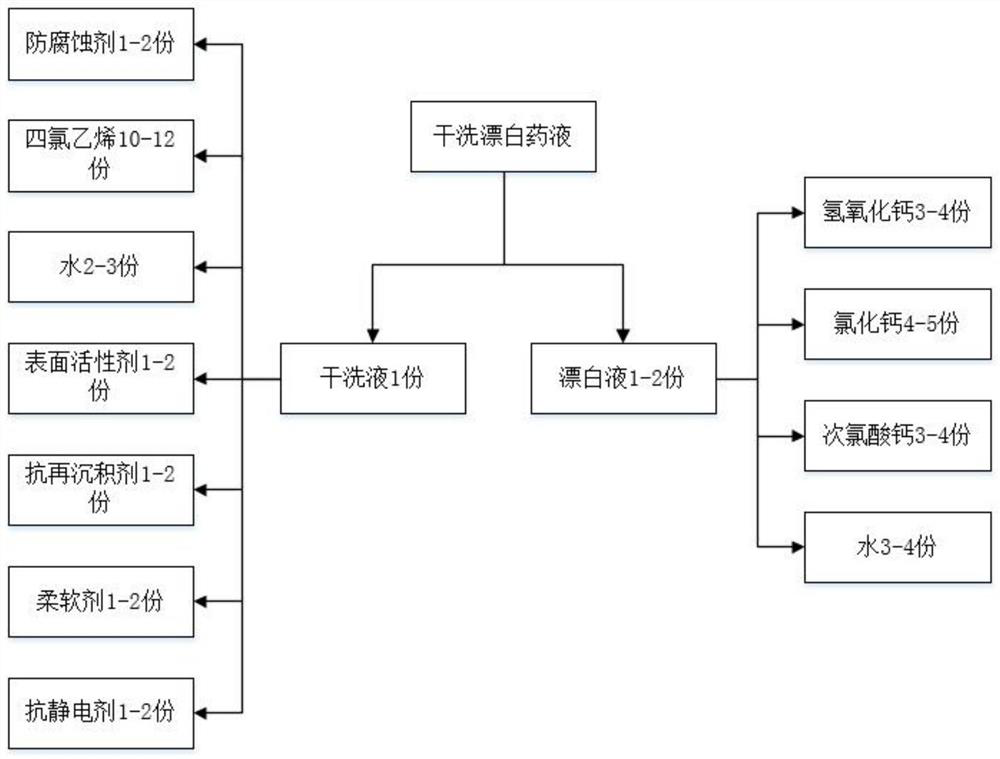

[0018] refer to figure 1 As shown in the figure, a dry-cleaning and bleaching liquid for wool includes dry-cleaning liquid and bleaching liquid, and the dry-cleaning liquid and bleaching liquid are proportioned according to the mass fraction of 1:1. The composition of anti-redeposition agent, softener and anti-static agent, wherein, anti-corrosion agent, tetrachloroethylene, water, surfactant, anti-redeposition agent, softener and anti-static agent are in mass fraction of 1:10:2:1: The ratio of 1:1:1 is carried out. The bleaching solution is composed of calcium hydroxide, calcium chloride, calcium hypochlorite and water. The mass fraction of calcium hydroxide, calcium chloride, calcium hypochlorite and water is 3: 4:3:3 for matching.

[0019] Specifically, the anticorrosion agent is composed of benzotriazole.

[0020] The composition of the surfactant is mixed with tricarboxylate and phospholipid in a mass fraction of 1:1.

[0021] The anti-redeposition agent consists of ci...

Embodiment 2

[0026] refer to figure 1 As shown in the figure, a dry cleaning and bleaching liquid for wool includes dry cleaning liquid and bleaching liquid. The composition of anti-redeposition agent, softener and anti-static agent, wherein, anti-corrosion agent, tetrachloroethylene, water, surfactant, anti-redeposition agent, softener and anti-static agent are in mass fractions of 1.5:11:2.5:1.5: The ratio of 1.5:1.5:1.5 is carried out. The bleaching solution is composed of calcium hydroxide, calcium chloride, calcium hypochlorite and water. The mass fraction of calcium hydroxide, calcium chloride, calcium hypochlorite and water is 3.5: 4.5:3.5:3.5 for matching.

[0027] Specifically, the anticorrosion agent is composed of benzotriazole.

[0028] The composition of the surfactant is mixed with tricarboxylate and phospholipid in a mass fraction of 1:1.

[0029] The anti-redeposition agent consists of citrate.

[0030] The softener is made up of quaternary ammonium salts and imidazolin...

Embodiment 3

[0034] refer to figure 1 As shown in the figure, a dry-cleaning and bleaching liquid for wool includes dry-cleaning liquid and bleaching liquid, and the dry-cleaning liquid and bleaching liquid are proportioned according to the mass fraction of 1:2. The composition of anti-redeposition agent, softener and anti-static agent, wherein, anti-corrosion agent, tetrachloroethylene, water, surfactant, anti-redeposition agent, softener and anti-static agent are in mass fraction of 2:12:3:2: The ratio of 2:2:2 is carried out. The bleaching solution is composed of calcium hydroxide, calcium chloride, calcium hypochlorite and water. The mass fraction of calcium hydroxide, calcium chloride, calcium hypochlorite and water is 4: 5:4:4 for matching.

[0035] Specifically, the anticorrosion agent is composed of benzotriazole.

[0036] The composition of the surfactant is mixed with tricarboxylate and phospholipid in a mass fraction of 1:1.

[0037] The anti-redeposition agent consists of ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com