A process control method for pbo fiber production

A process control and fiber technology, which is applied in the control field of poly-p-phenylenebenzobisoxazole (PBO) fiber polymerization process production, can solve the problems of TPA solubility and high solution viscosity, etc., and achieve easy and feasible stirring , the effect of reducing solid content and shortening the process time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

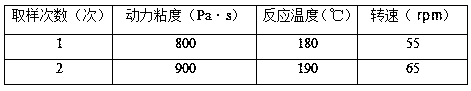

Embodiment 1

[0033] The present embodiment proposes a process control method for PBO fiber production, the steps of the process control method are as follows:

[0034] A, degassing, after polyphosphoric acid is heated, drop into mixed degassing still, then drop into phosphorus pentoxide, 4,6-diaminoresorcinol hydrochloride and terephthalic acid, carry out degassing;

[0035] B, pre-polymerization, the material obtained by the degassing of step A is pre-polymerized, and terephthalic acid is added in the pre-polymerization process to obtain a prepolymer material;

[0036] C, post-polymerization, the pre-polymer material and terephthalic acid are sent into the screw reactor for post-polymerization to obtain the post-polymer material;

[0037] D. Spinning, the polymer material is spun to obtain PBO fiber.

[0038] In the above-mentioned steps, the ratio of the molar weight of the 4,6-diaminoresorcinol hydrochloride input in step A to the sum of the terephthalic acid molar weight input in step...

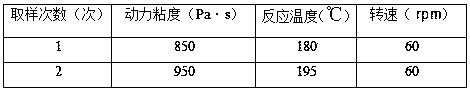

Embodiment 2

[0040] The present embodiment proposes a process control method for PBO fiber production, the steps of the process control method are as follows:

[0041] A, degassing, after polyphosphoric acid is heated, drop into mixed degassing still, then drop into phosphorus pentoxide, 4,6-diaminoresorcinol hydrochloride and terephthalic acid, carry out degassing;

[0042] B, pre-polymerization, the material obtained by the degassing of step A is pre-polymerized, and terephthalic acid is added in the pre-polymerization process to obtain a prepolymer material;

[0043] C, post-polymerization, the pre-polymer material and terephthalic acid are sent into the screw reactor for post-polymerization to obtain the post-polymer material;

[0044] D. Spinning, the polymer material is spun to obtain PBO fiber.

[0045] In the above-mentioned steps, the ratio of the molar weight of the 4,6-diaminoresorcinol hydrochloride input in step A to the sum of the terephthalic acid molar weight input in steps ...

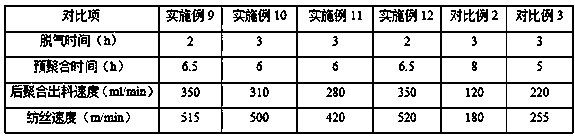

Embodiment 3

[0047] The present embodiment proposes a process control method for PBO fiber production, the steps of the process control method are as follows:

[0048] A, degassing, after polyphosphoric acid is heated, drop into mixed degassing still, then drop into phosphorus pentoxide, 4,6-diaminoresorcinol hydrochloride and terephthalic acid, carry out degassing;

[0049] B, pre-polymerization, the material obtained by the degassing of step A is pre-polymerized, and terephthalic acid is added in the pre-polymerization process to obtain a prepolymer material;

[0050] C, post-polymerization, the pre-polymer material and terephthalic acid are sent into the screw reactor for post-polymerization to obtain the post-polymer material;

[0051] D. Spinning, the polymer material is spun to obtain PBO fiber.

[0052] In the above-mentioned steps, the ratio of the molar weight of the 4,6-diaminoresorcinol hydrochloride input in step A to the sum of the terephthalic acid molar weight input in step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com