Sr-contained panel solar aluminum alloy plating layer and preparation method thereof

A flat-panel solar energy and aluminum alloy technology, applied in metal material coating process, coating, fusion spraying, etc., can solve the problems of low-efficiency resource utilization, over-exploitation of resources, etc., to improve high-temperature strength and volume, not easy to fall off, Good corrosion resistance and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

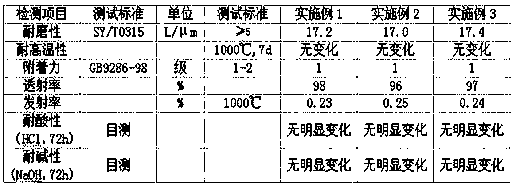

Examples

Embodiment 1

[0019] A Sr-containing flat solar aluminum alloy coating and a preparation method thereof, the aluminum alloy coating material is prepared from raw materials in the following mass proportions: 0.4%Sr, 2.5%Ti, 15%Zn, 9%Si, 0.7%La, 0.3% Ce, 0.25% Zr, and the balance is aluminum.

[0020] The preparation method of aluminum alloy coating comprises the following steps:

[0021] (1) Add aluminum ingots or molten aluminum into the melting furnace, heat it to melt it completely and keep it warm at 750°C;

[0022] (2) Then add Sr, Ti, Zn, Si, La, Ce and Zr according to the proportion of the formula, and stir evenly;

[0023] (3) Then refine the alloy melt in the furnace, add refining agent to the alloy melt, and stir evenly, and the melt refining is completed in a closed environment;

[0024] (4) Slag removal, degassing and modification agent NiC after refining 3 Processed to obtain an aluminum alloy plating solution;

[0025] (5) Clean the surface of the solar panel substrate, spr...

Embodiment 2

[0029] A Sr-containing flat solar aluminum alloy coating and a preparation method thereof. The aluminum alloy coating material is prepared from raw materials in the following mass proportions: 0.3%Sr, 2%Ti, 10%Zn, 8%Si, 0.65%La, 0.1% Ce, 0.2% Zr, and the balance is aluminum.

[0030] The preparation method of aluminum alloy coating comprises the following steps:

[0031] (1) Add aluminum ingots or molten aluminum into the melting furnace, heat it to melt it completely and keep it warm at 700°C;

[0032] (2) Then add Sr, Ti, Zn, Si, La, Ce and Zr according to the proportion of the formula, and stir evenly;

[0033] (3) Then refine the alloy melt in the furnace, add refining agent to the alloy melt, and stir evenly, and the melt refining is completed in a closed environment;

[0034] (4) Slag removal, degassing and modification agent NiC after refining 3 Processed to obtain an aluminum alloy plating solution;

[0035] (5) Clean the surface of the solar panel substrate, spray...

Embodiment 3

[0039] A Sr-containing flat solar aluminum alloy coating and its preparation method, the aluminum alloy coating material is prepared from the following raw materials in mass proportions: 0.5%Sr, 3%Ti, 20%Zn, 10%Si, 0.75%La, 0.6% Ce, 0.3% Zr, and the balance is aluminum.

[0040] The preparation method of aluminum alloy coating comprises the following steps:

[0041] (1) Add aluminum ingots or molten aluminum into the melting furnace, heat it to melt it completely and keep it warm at 800°C;

[0042] (2) Then add Sr, Ti, Zn, Si, La, Ce and Zr according to the proportion of the formula, and stir evenly;

[0043] (3) Then refine the alloy melt in the furnace, add refining agent to the alloy melt, and stir evenly, and the melt refining is completed in a closed environment;

[0044] (4) Slag removal, degassing and modification agent NiC after refining 3 Processed to obtain an aluminum alloy plating solution;

[0045] (5) Clean the surface of the solar panel substrate, spray even...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com