A kind of zinc alloy and its manufacturing method

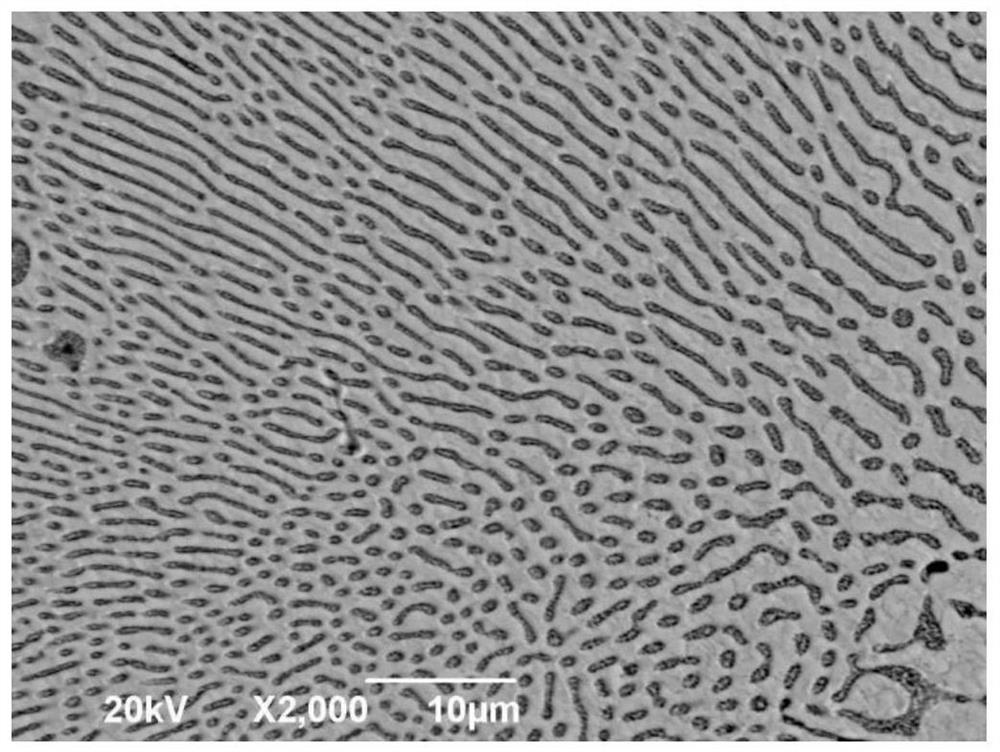

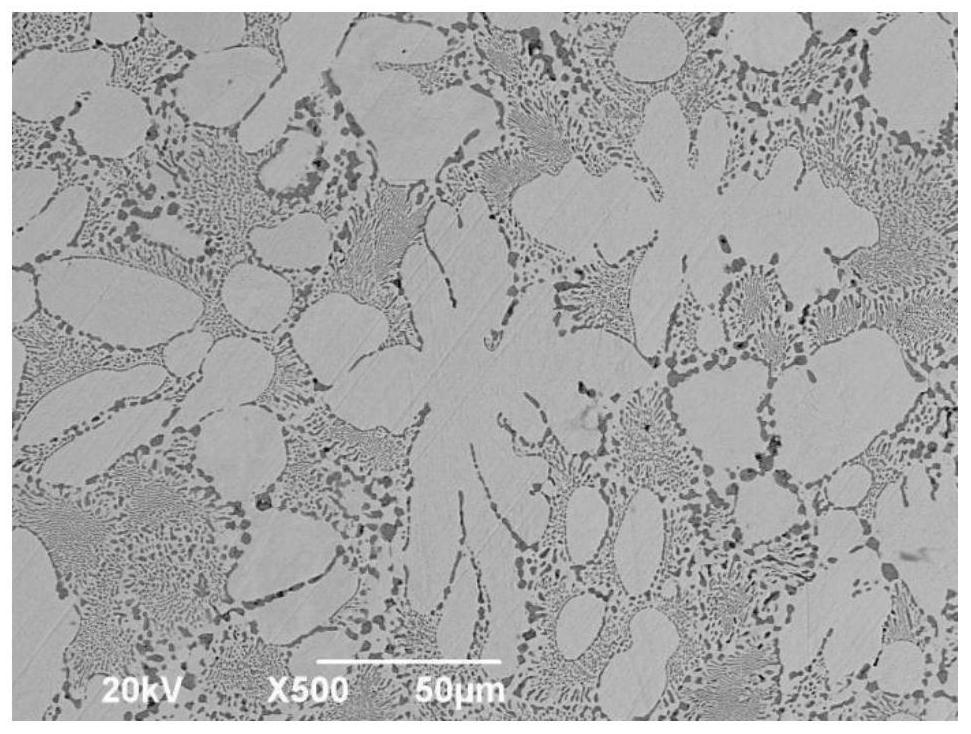

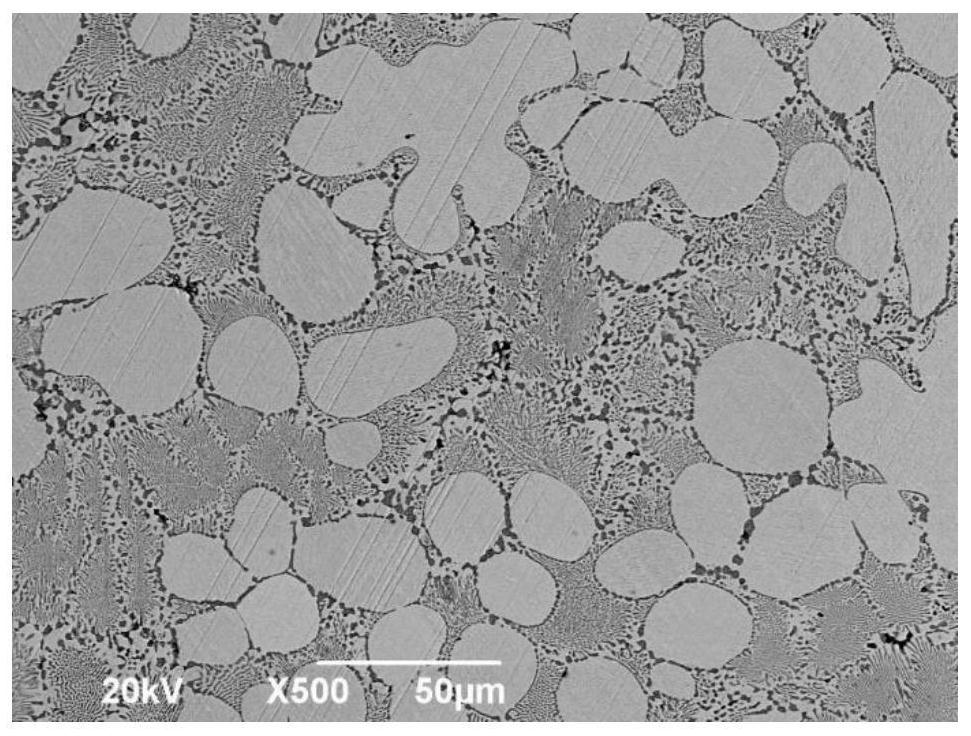

A zinc alloy and modifier technology, applied in the field of zinc alloy smelting, can solve problems such as uneven grain size, size change, and low creep strength, and achieve the elimination of segregation that is not serious in rapid cooling and the reduction of lamellar thickness , The effect of increasing heterogeneous crystal nuclei

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A zinc alloy, the content of each element of the zinc alloy is: Al4%-7%, Cu0.5%-1.5%, Ti0.4%-0.7%, B0.07%-0.1%, Mg0.02%-0.025% , other 0.1%-1%, Zn balance;

[0032] The method of manufacturing the zinc alloy comprises the following stages;

[0033] 1) Preparation before production

[0034] ① Raw material preparation: Prepare Zn-Al4 alloy 99kg-99.35kg, AlTi5B master alloy 0.55kg-0.9kg, ZnCl 2 Refining agent 0.05kg-0.15kg, sufficient amount of pure aluminum, compound salt modifier composed of K2TiF6 and KBF4 with a mass ratio of 4:1 0.7kg-0.8kg;

[0035] ②Equipment and tooling preparation: Prepare graphite crucible with graphite mechanical stirring device, vacuum melting equipment with built-in gas channel and graphite crucible, protective atmosphere furnace, alumina ceramic structural parts, primary coarse screen made of alumina ceramic , A filter structure composed of an online filter screen made of carbon fiber ceramic composite material lined on the outer surface o...

Embodiment 2

[0044] The whole is consistent with Example 1, the difference is:

[0045] The modificator is TiCl4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com