A kind of impregnation method of high-pressure negative electrode power battery

A power battery, high-pressure compaction technology, applied in battery electrodes, secondary battery manufacturing, circuits, etc., can solve the problems of high liquid loss of batteries, low-porosity negative electrode sheet infiltration difficulties, etc., to improve battery life and calendar life The effect of enhancing and avoiding the phenomenon of lithium precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

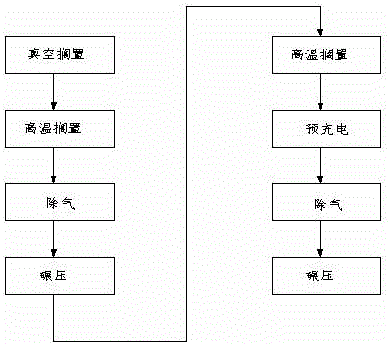

[0024] The flow chart of infiltration method of the present invention sees figure 1 ,Specific steps are as follows:

[0025] A. Vacuum shelving: Place the battery cell that has just been injected with electrolyte but has not been sealed once in a vacuum box. The battery cell is placed at an angle of 60-90 degrees. Time 10 minutes to 15 minutes;

[0026] B. Shelving at high temperature: Aging the battery core after vacuum shelving and sealing once at a temperature of 33°C-38°C, placing the battery cell at an angle of 30-60 degrees, with the air bag of the battery cell upward, and the shelf time is 10 hours to 12 hours;

[0027] C. Degassing: Take out the battery cell after high temperature storage, and perform air extraction and edge sealing on the vacuum pumping equipment. The vacuum degree is -0.092MPa, and the pumping time is 2 seconds to reduce the internal pressure of the cell The liquid loss of the cell after gas is 0.2g~0.8g, while the liquid loss of the normal temper...

Embodiment 2

[0034] The flow chart of infiltration method of the present invention sees figure 1 ,Specific steps are as follows:

[0035] A. Vacuum shelving: Place the battery cell that has just been injected with electrolyte but has not been sealed once in a vacuum box. The battery cell is placed at an angle of 60-90 degrees. Time 10 minutes to 15 minutes;

[0036] B. Shelving at high temperature: Aging the battery core after vacuum shelving and sealing once at a temperature of 33°C-38°C, placing the battery cell at an angle of 30-60 degrees, with the air bag of the battery cell upward, and the shelf time is 10 hours;

[0037] C. Degassing: Take out the battery cell after high temperature storage, and perform air extraction and edge sealing on the vacuum pumping equipment. The vacuum degree is -0.092MPa, and the pumping time is 2 seconds to reduce the internal pressure of the cell The liquid loss of the cell after gas is 0.2g, while the liquid loss of the normal temperature immersion me...

Embodiment 3

[0044] The flow chart of infiltration method of the present invention sees figure 1 ,Specific steps are as follows:

[0045] A. Vacuum shelving: Place the battery cell that has just been injected with electrolyte but has not been sealed once in a vacuum box. The battery cell is placed at an angle of 60-90 degrees. Time 10 minutes to 15 minutes;

[0046] B. Shelving at high temperature: Aging the batteries after vacuum shelving and sealing once at a temperature of 33°C-38°C, placing the batteries at an angle of 30-60 degrees, with the airbag of the batteries facing upwards, and placing them for 12 hours;

[0047] C. Degassing: Take out the battery cell after high temperature storage, and perform air extraction and edge sealing on the vacuum pumping equipment. The vacuum degree is -0.092MPa, and the pumping time is 2 seconds to reduce the internal pressure of the cell The liquid loss of the cell after gas is 0.8g, while the liquid loss of the normal temperature immersion metho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com