Application of organic coatings, pole pieces for lithium-ion batteries and their applications, lithium-ion batteries and their applications

A lithium-ion battery, organic technology, applied in non-aqueous electrolyte battery electrodes, coatings, secondary batteries, etc., can solve the problems of increased cost, increased complexity, limited volume energy density of lithium-ion batteries, etc., and achieves good infiltration. The effect of improving the electrochemical performance and reducing the internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0091] 1. Application of organic coatings as separators in the preparation of lithium-ion batteries

[0092] The organic coating is formed by curing the paint, which includes 20g of vinylidene fluoride-hexafluoropropylene copolymer, 210g of acetone and 34.4g of ethanol.

[0093] 2. Preparation of coating

[0094] Add 20 g of vinylidene fluoride-hexafluoropropylene copolymer powder into 210 g of acetone solution, dissolve the copolymer powder and heat at 50° C. for 1.2 hours to obtain a transparent and uniform mixed solution. Further, 34.4 g of ethanol was added to the mixed solution to form a blended solution, and the formed blended solution was heated at 50° C. for 0.8 hours to obtain a coating for coating.

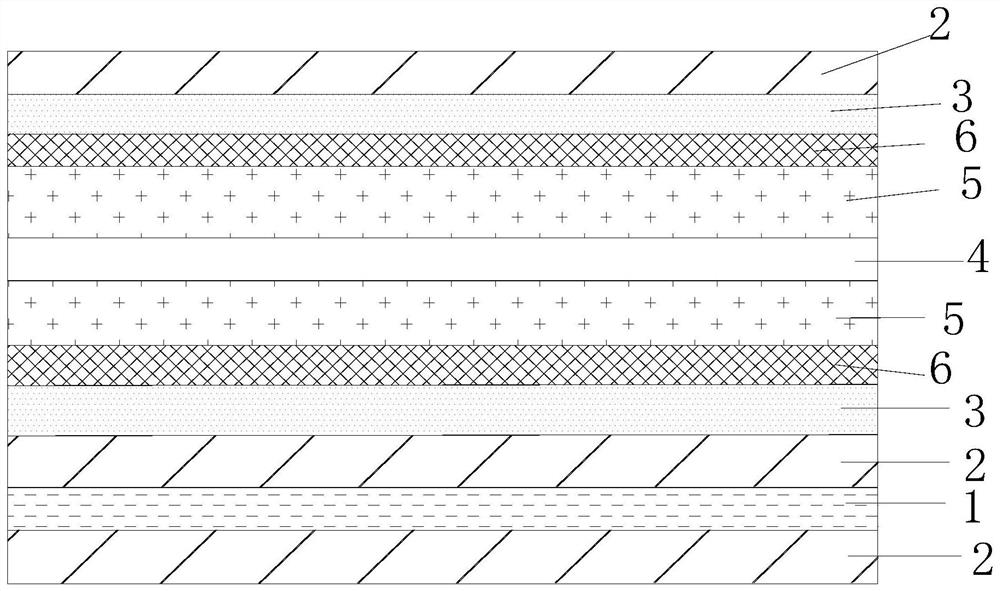

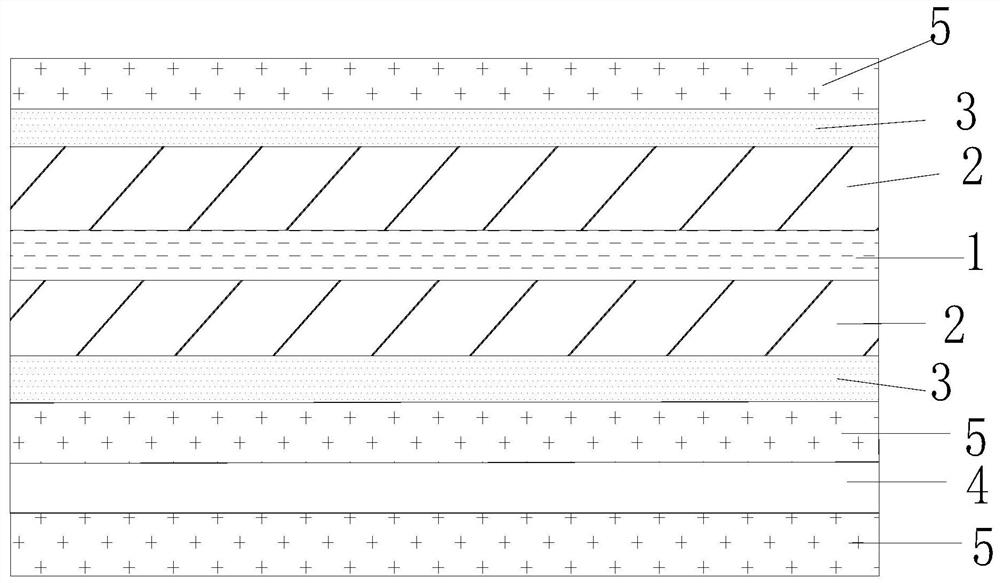

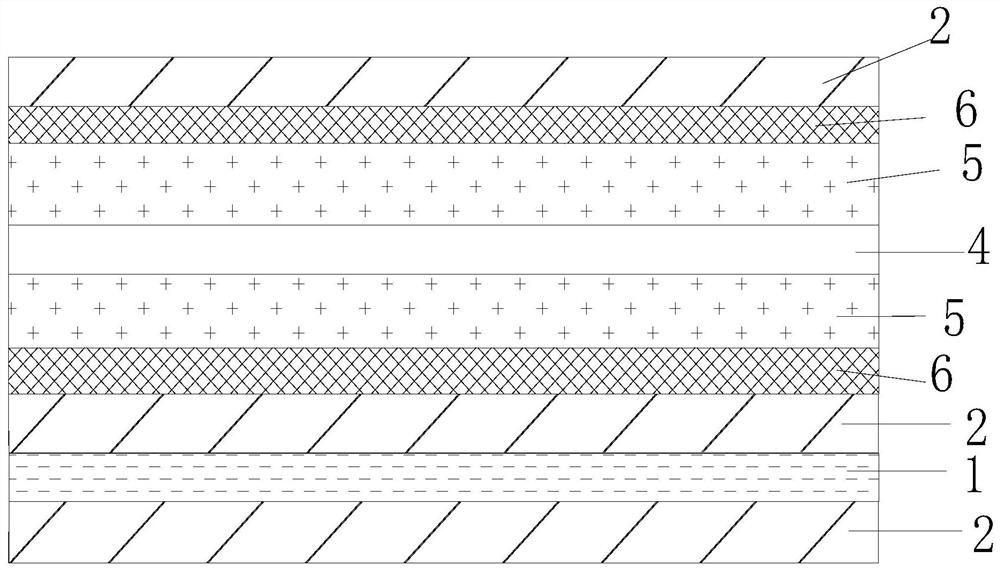

[0095] 3. Pole pieces for lithium-ion batteries

[0096] ① Coating the negative electrode active material layer on the surface of the negative electrode sheet

[0097] The preparation of negative electrode slurry: mix according to the weight ratio of negative electrod...

Embodiment 2

[0107] 1. Application of organic coatings as separators in the preparation of lithium-ion batteries

[0108] The organic coating is formed by curing the paint, which includes 10g of vinylidene fluoride-hexafluoropropylene copolymer, 105g of acetone and 27g of ethanol.

[0109] 2. Preparation of coating

[0110] Add 10 g of vinylidene fluoride-hexafluoropropylene copolymer powder into 105 g of acetone solution, dissolve the copolymer powder and heat at 50° C. for 1 hour to obtain a transparent and uniform mixed solution. Further, 27 g of ethanol was added to the mixed solution to form a blended solution, and the formed blended solution was heated at 50° C. for 1 hour to obtain a coating material for coating.

[0111] 3. Pole pieces for lithium-ion batteries

[0112] ① Coating the negative electrode active material layer on the surface of the negative electrode sheet

[0113] Preparation of negative electrode slurry: mix according to the weight ratio of negative electrode act...

Embodiment 3

[0123] 1. Application of organic coatings as separators in the preparation of lithium-ion batteries

[0124] The organic coating is formed by curing the paint, which includes 10g of vinylidene fluoride-hexafluoropropylene copolymer, 105g of acetone and 34.4g of ethanol.

[0125] 2. Preparation of coating

[0126] Add 10 g of vinylidene fluoride-hexafluoropropylene copolymer powder into 105 g of acetone solution, dissolve the copolymer powder and heat at 50° C. for 1.5 hours to obtain a transparent and uniform mixed solution. Further, 34.4 g of ethanol was added to the mixed solution to form a blended solution, and the formed blended solution was heated at 50° C. for 0.5 hour to obtain a coating for coating.

[0127] 3. Pole pieces for lithium-ion batteries

[0128] ① Coating the negative electrode active material layer on the surface of the negative electrode sheet

[0129] Preparation of negative electrode slurry: mix according to the weight ratio of negative electrode act...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com