Battery pole piece and preparation method thereof, battery cell and battery

A battery pole piece and cell technology, which is applied in battery electrodes, electrode manufacturing, electrode collector coating, etc., can solve the negative impact of battery cycle and rate performance, reduce the compaction density of battery pole pieces, and increase the gas permeability of the separator. and other problems, to achieve good electrophilic performance, improve the ability to absorb electrolyte, and eliminate the effect of softening the cell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

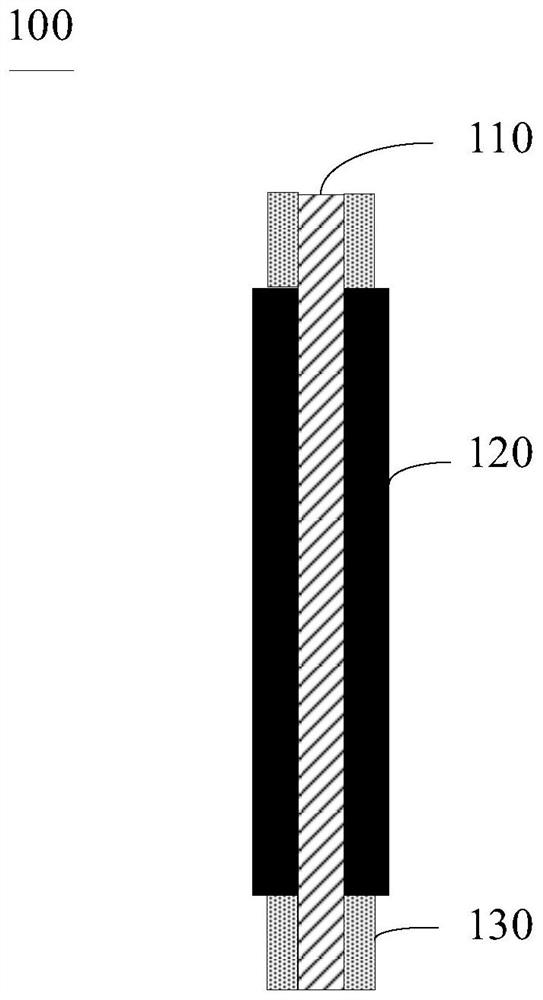

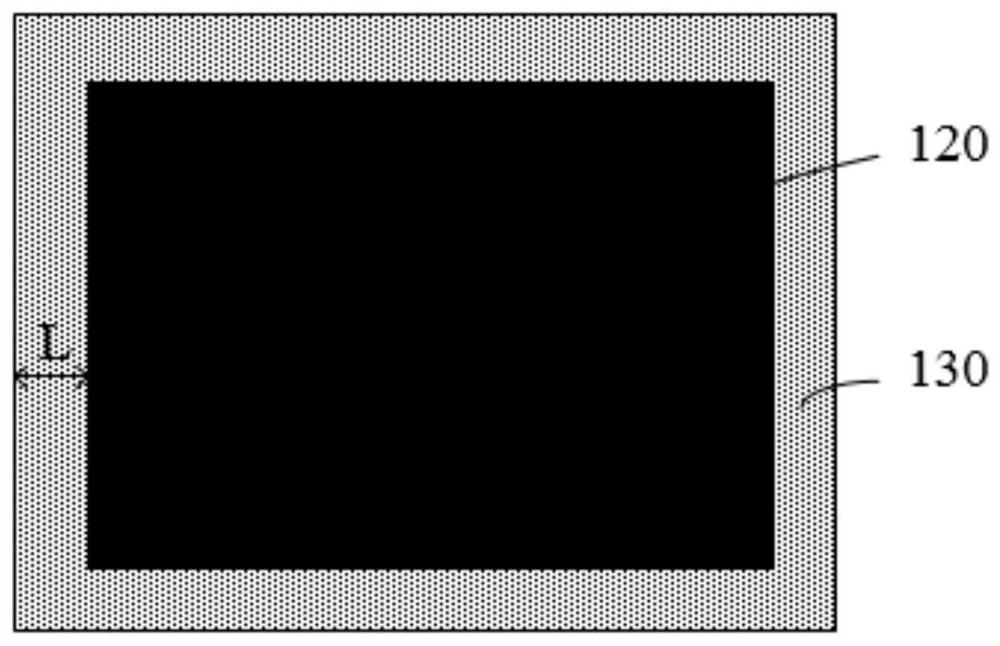

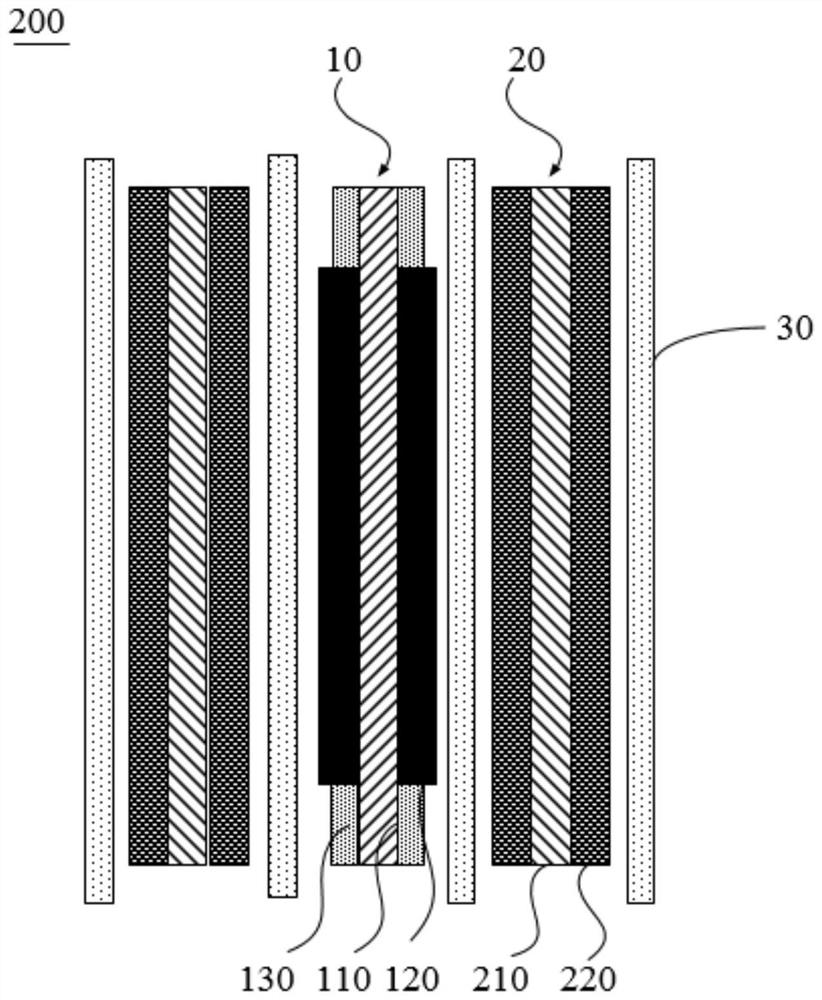

[0049] Another embodiment of the present invention provides a method for preparing a battery pole piece, comprising the following steps:

[0050] A current collector is provided, and the surface of the current collector has a first coating area and a second coating area surrounding the first coating area; the first coating area is coated to form an active material coating, and the second coating area is coated Form a liquid-absorbent coating; wherein, the liquid-absorbent coating contains liquid-retaining additives, and the liquid-retaining additives are selected from the blend powder of nitrile and polyvinyl chloride, polypropylene micropowder, ultra-high molecular weight polyethylene powder and linear crystalline At least one of the polyvinylidene fluoride polymers.

[0051] In one embodiment, the raw materials of the paint forming the liquid-absorbing coating include 85-100.8 parts by weight of liquid-retaining additives, 65-89 parts by weight of ceramic microsphere powder,...

Embodiment 1

[0077] 1. Preparation of absorbent coating:

[0078] Boehmite microsphere powder, N-methylpyrrolidone, sodium carboxymethyl cellulose, linear crystalline polyvinylidene fluoride polymer and γ-methacryloxypropyltrimethoxysilane were mixed in a mass ratio of 7.7 : 5.8: 0.8: 9.3: 0.03 into the homogenizer mixer, the order of addition is to first add N-methylpyrrolidone, sodium carboxymethyl cellulose and linear crystalline polyvinylidene fluoride polymer into the mixer, with a revolution of 10r / Min, rotate at 150r / min and stir for 50min, then add boehmite microsphere powder and γ-methacryloxypropyltrimethoxysilane to the mixer, vacuumize to -90KPa, continue stirring at the same speed for 210min, After the uniformly dispersed high liquid absorption coating is obtained, the coating is placed in a transfer tank and stirred at a low speed of 15r / min for later use.

[0079] 2. Preparation of positive pole piece and negative pole piece

[0080] Apply the positive electrode active ma...

Embodiment 2

[0085]Example 2 is basically the same as Example 1, except that in the liquid-absorbing coating of Example 2, boehmite microsphere powder, N-methylpyrrolidone, sodium carboxymethylcellulose, and linear crystalline polyvinylidene fluoride The mass ratio of polymer to γ-methacryloxypropyltrimethoxysilane is 8.9:7.7:1.3:8.5:0.05.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com