Complete rectifying device for regeneration of waste oil

A technology for regeneration of waste oil and a complete set of devices, which is applied in the field of oil purifiers, can solve the problems of improving quality, single quality, high sulfur and impurities in oil, and achieves the effects of not easy scaling and damage, reducing production costs, and having a scientific and reasonable structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

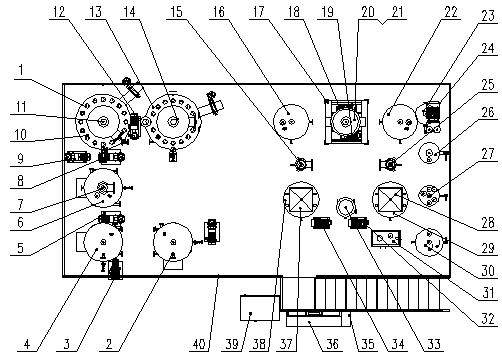

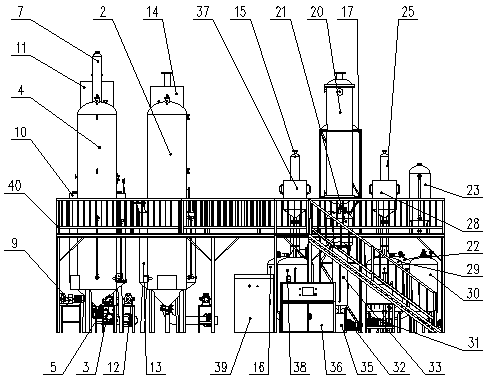

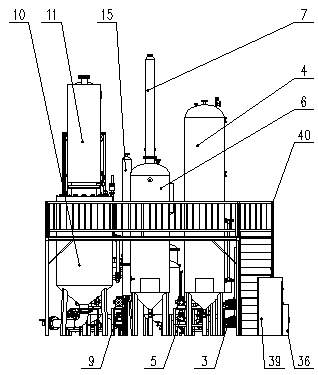

[0033] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , a complete set of waste oil regeneration and rectification equipment, on the ground and on the equipment mounting frame 40, a pretreatment tank, a reaction kettle 6, a fractionation tower 7, a distillation tower 10, a catalytic tower 11, a reboiler tower 13, and a refining tower are installed in an orderly manner. Distillation tower 14, cooling tower 20, gas-liquid separator 21, semi-finished product tank, desulfurization tower, light oil storage tank 23, distillation vacuum pump unit 24, filter vacuum pump unit 31, steam-water separator 26, buffer tank 27, filter tank, isolation Cupping tank 30, oil spill tank 33, pneumatic valve box 35, console 36, power cabinet 39 are connected in order with pipe fittings, oil pump, electric wire, in described reactor 6, distillation tower 10, catalytic tower 11, again The boiling tower 13 and the rectifying tower 14 are provided with a vertical electric heating t...

Embodiment 2

[0035] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , a complete set of waste oil regeneration and rectification equipment, on the ground and on the equipment mounting frame 40, a pretreatment tank, a reaction kettle 6, a fractionation tower 7, a distillation tower 10, a catalytic tower 11, a reboiler tower 13, and a refining tower are installed in an orderly manner. Distillation tower 14, cooling tower 20, gas-liquid separator 21, semi-finished product tank, desulfurization tower, light oil storage tank 23, distillation vacuum pump unit 24, filter vacuum pump unit 31, steam-water separator 26, buffer tank 27, filter tank, isolation Cupping tank 30, oil spill tank 33, pneumatic valve box 35, console 36, power cabinet 39 are connected in order with pipe fittings, oil pump, electric wire, in described reactor 6, distillation tower 10, catalytic tower 11, again The boiling tower 13 and the rectifying tower 14 are provided with a vertical electric heating t...

Embodiment 3

[0037] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , a complete set of waste oil regeneration and rectification equipment, on the ground and on the equipment mounting frame 40, a pretreatment tank, a reaction kettle 6, a fractionation tower 7, a distillation tower 10, a catalytic tower 11, a reboiler tower 13, and a refining tower are installed in an orderly manner. Distillation tower 14, cooling tower 20, gas-liquid separator 21, semi-finished product tank, desulfurization tower, light oil storage tank 23, distillation vacuum pump unit 24, filter vacuum pump unit 31, steam-water separator 26, buffer tank 27, filter tank, isolation Cupping tank 30, oil spill tank 33, pneumatic valve box 35, console 36, power cabinet 39 are connected in order with pipe fittings, oil pump, electric wire, in described reactor 6, distillation tower 10, catalytic tower 11, again The boiling tower 13 and the rectifying tower 14 are provided with a vertical electric heating t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com