Deep desulfurization method for LF furnace

A deep desulfurization and steel type technology, applied in the field of steelmaking and refining, can solve the problems of desulfurization capacity decline, difficulty in achieving low-sulfur smelting goals, and inability to achieve ultra-low-sulfur steel smelting, so as to ensure desulfurization quality and high cleanliness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to deepen the understanding of the present invention, the present invention will be described in further detail below with reference to the embodiments. The embodiments are only used to explain the present invention and do not constitute a limitation on the protection scope of the present invention.

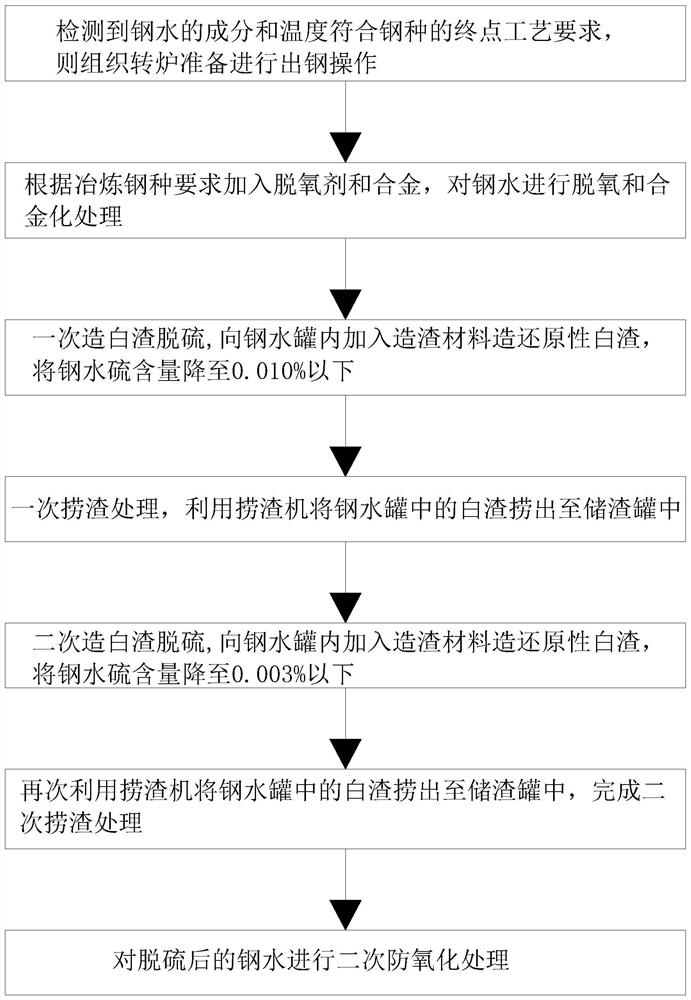

[0025] according to figure 1 As shown, the present embodiment proposes a LF furnace deep desulfurization method, comprising the following steps:

[0026] Step 1: After the end of converter smelting, when it is detected that the composition and temperature of molten steel meet the end-point process requirements of the steel grade, the converter is organized to prepare for the tapping operation;

[0027] Step 2: First calculate the yield of alloying elements, then determine the type and proportion of deoxidizer and alloy added based on the yield of alloying elements, add deoxidizer and alloy according to the requirements of smelting steel before tapping, The molten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com