Method for generating electromagnetic force with temporal and spatial variation in conducting liquid by adopting fluid driving

A conductive liquid, space-time change technology, applied in the field of electromagnetic force, semiconductor material preparation, electromagnetic metallurgy, can solve the problems of increased concentration segregation, poor spatial distribution adjustability, poor solute redistribution effect, etc., to expand the scope of application fields, Improved macro segregation, flexible and diverse designs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In the following, the method of using fluid to drive the electromagnetic force that generates spatiotemporal changes in the conductive liquid proposed by the present invention will be described in detail with reference to the accompanying drawings.

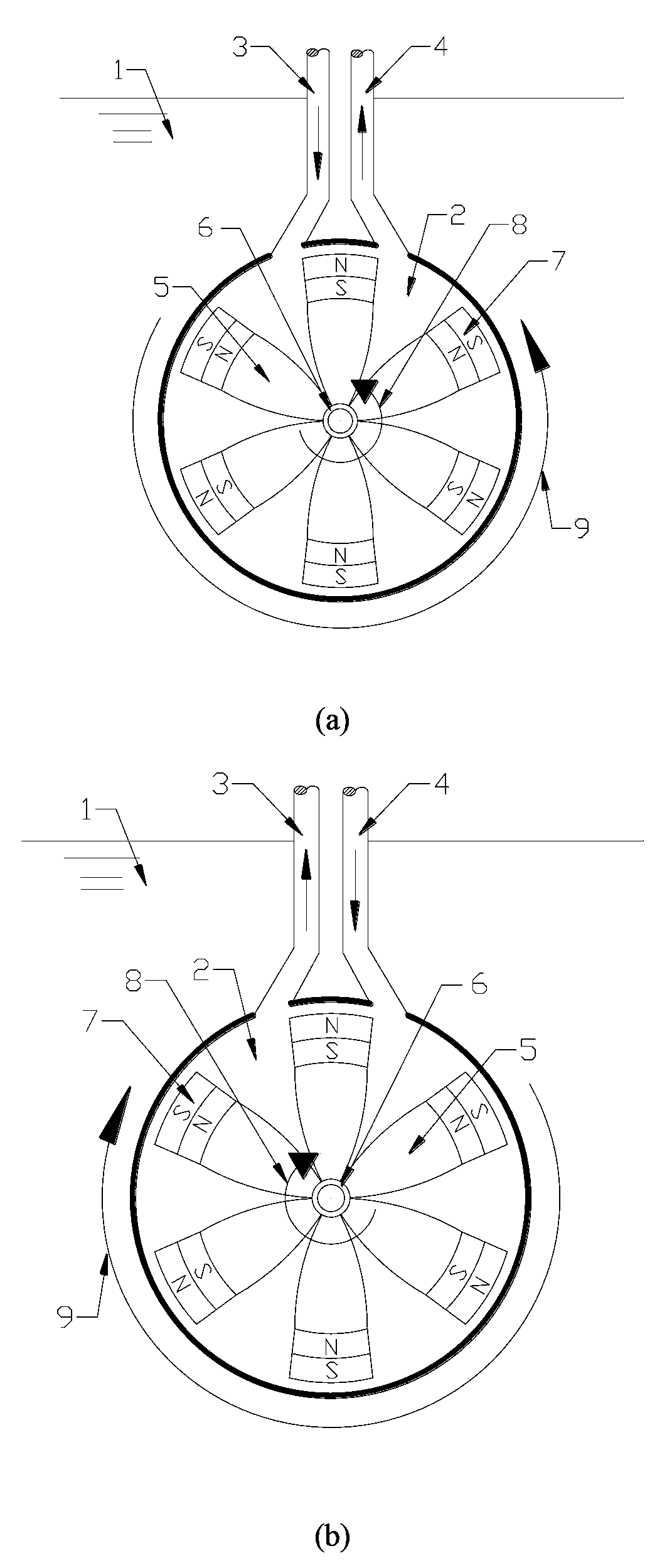

[0041] The inventive method has multiple different schemes, wherein the structure of the magnetic driver designed by the first scheme is as follows: figure 1 shown, including the following steps:

[0042] (1) A cylindrical cavity 2 is formed in the conductive liquid 1, and the cavity is provided with a first channel port 3 and a second channel port 4 for driving fluid;

[0043] (2) Place the turbine blade 5 in the cylindrical cavity 1, install the turbine blade 5 on the bearing 6, and install the bearing 6 coaxially with the cylindrical cavity 2;

[0044] (3) Relatively fixing the permanent magnet 7 and the turbine blade 5;

[0045] (4) Make the driving fluid enter or flow out from the first channel port 3 or the second c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com