Method for operating a filter rod machine and filter rod machine

A technology of filter tips and bundles, which is applied in applications, e-liquid filter elements, tobacco, etc., can solve the problem that it is impossible to identify tow twists, etc., and achieve the effect of reliable identification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

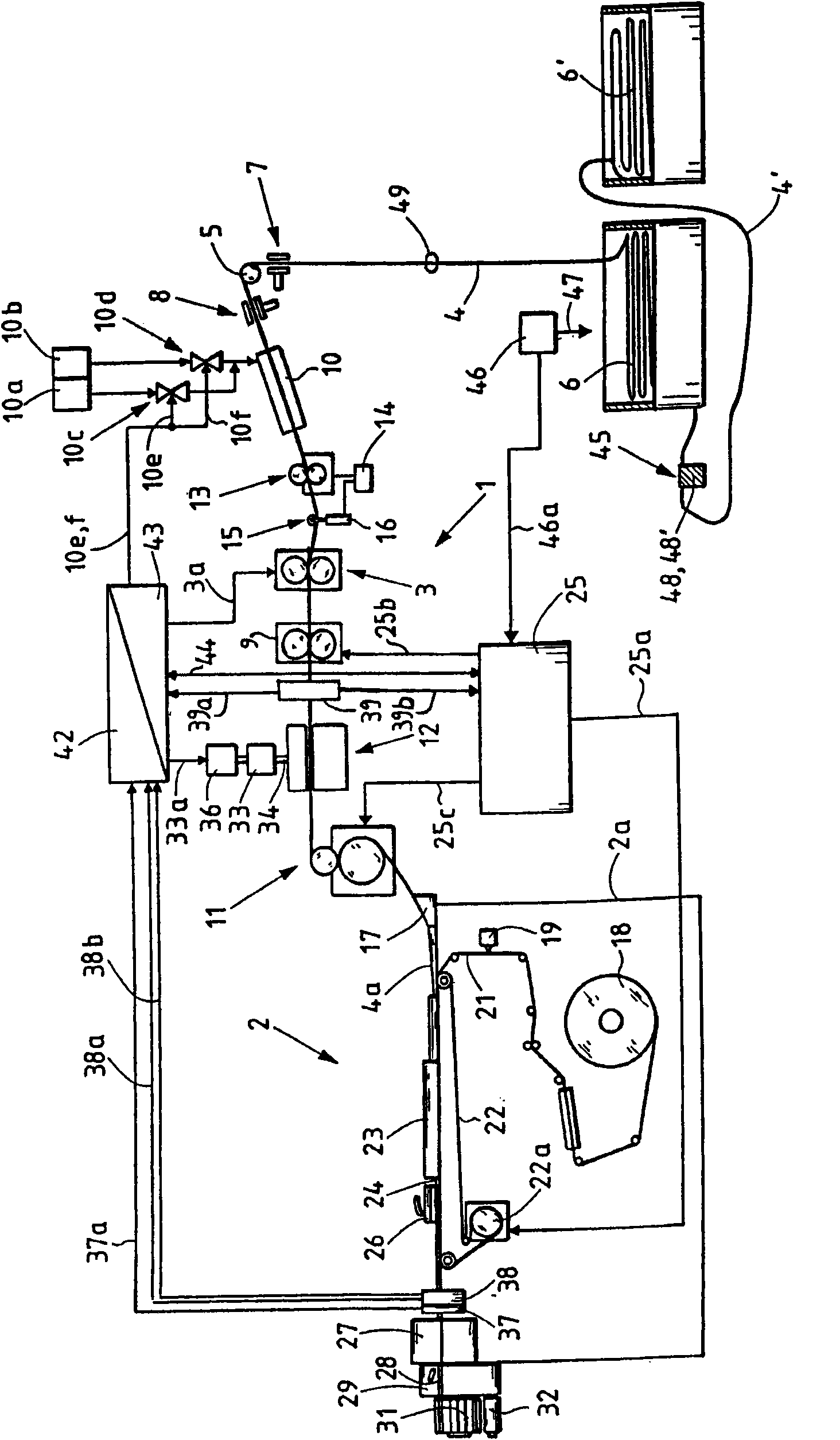

[0119] figure 1 A schematic side view of an embodiment according to the invention of a filter sliver machine is shown, which comprises a preparation device 1 and a processing device 2 . With the filter rod machine, filter rods 24 are produced, which are used, for example, to manufacture filter rods 28 for cigarettes and other smokeable articles. The shown equipment for the manufacture of filter rods 28 may for example be of the type marketed by the applicant of the product line KDF. The plant comprises two main components (Hauptbaugruppe): a preparation plant 1 for filter tow supplied in the form of endless (endlosen) filter material strip 4 and a processing plant for the manufacture of wrapped filter rods 28 2.

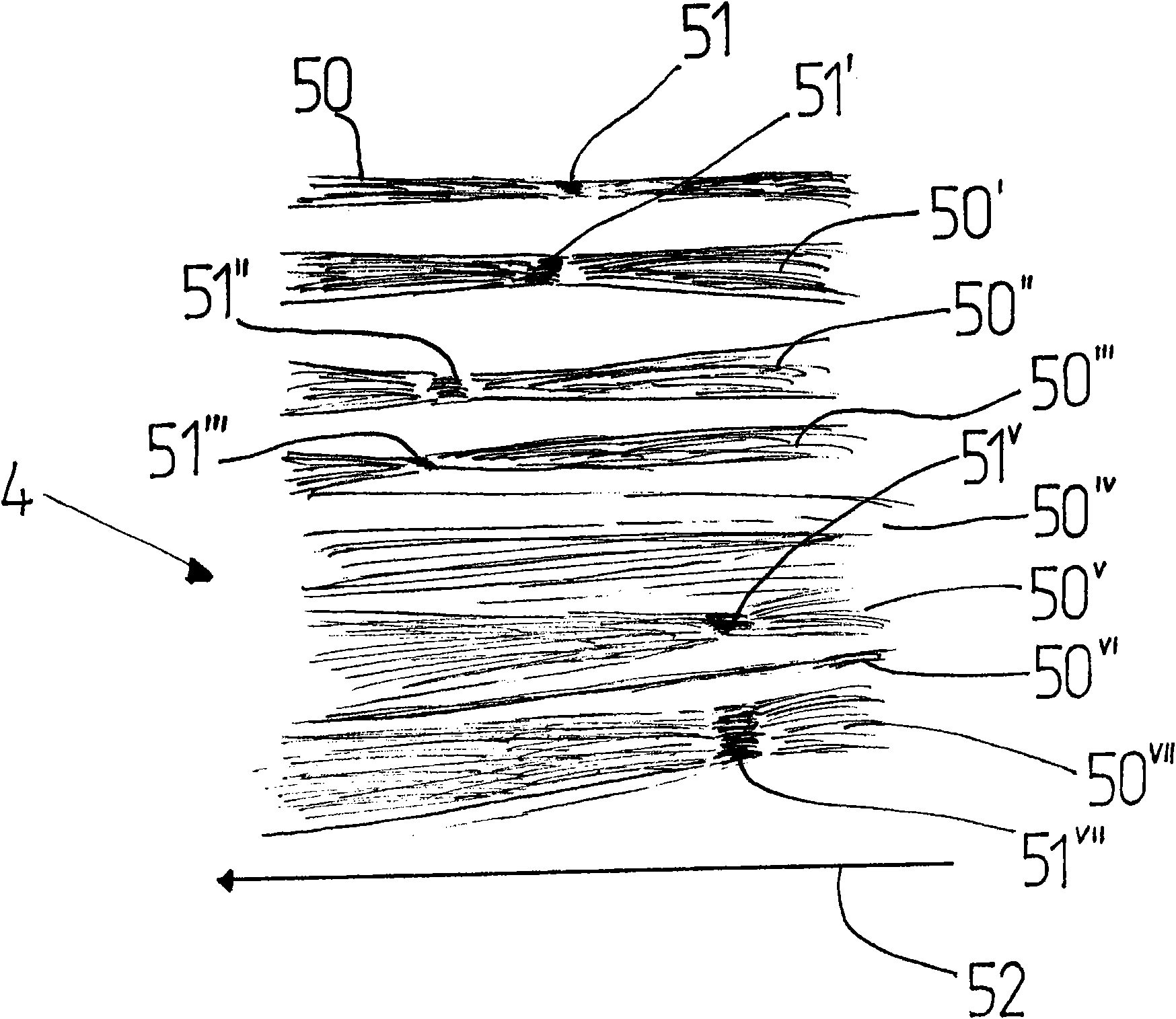

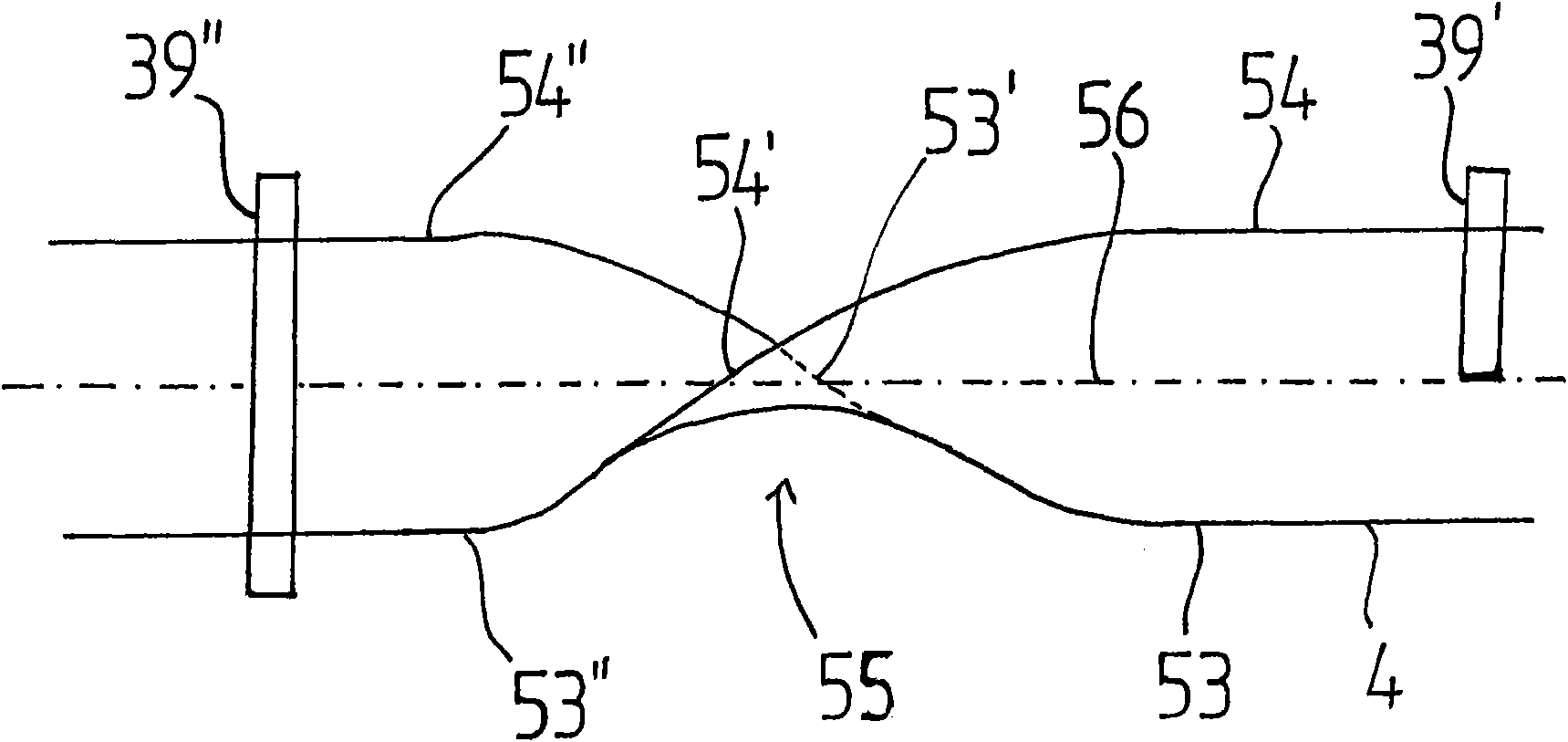

[0120] The preparation device 1 has a pair of rollers 3 for continuously withdrawing an endless web of filter tip material 4 from a package 6 . After being removed from the bale 6, the filter tow band 4 follows its up to 20 m long path to the pair of rolls 3 (on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com