Patents

Literature

82results about How to "Good centering effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

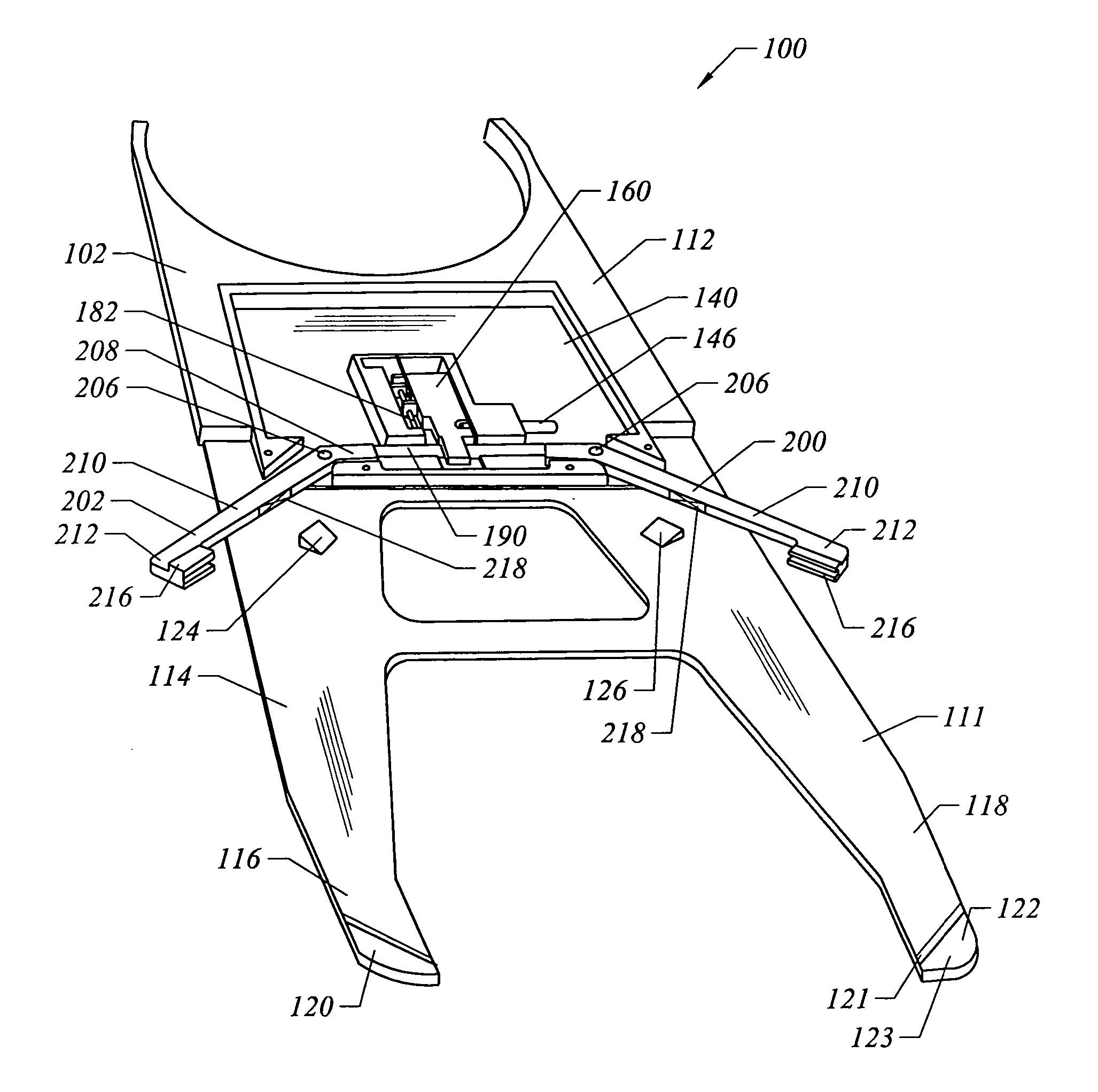

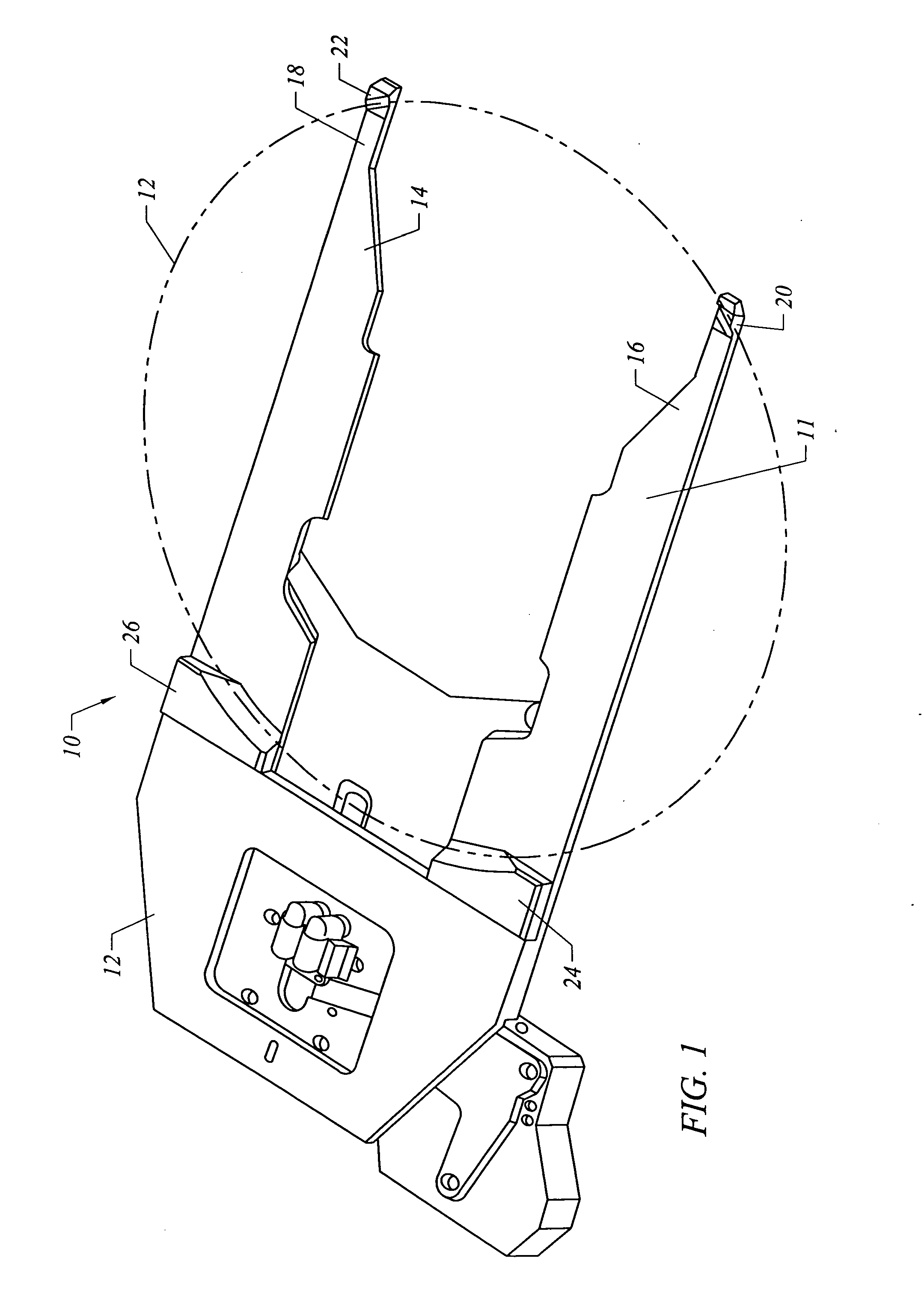

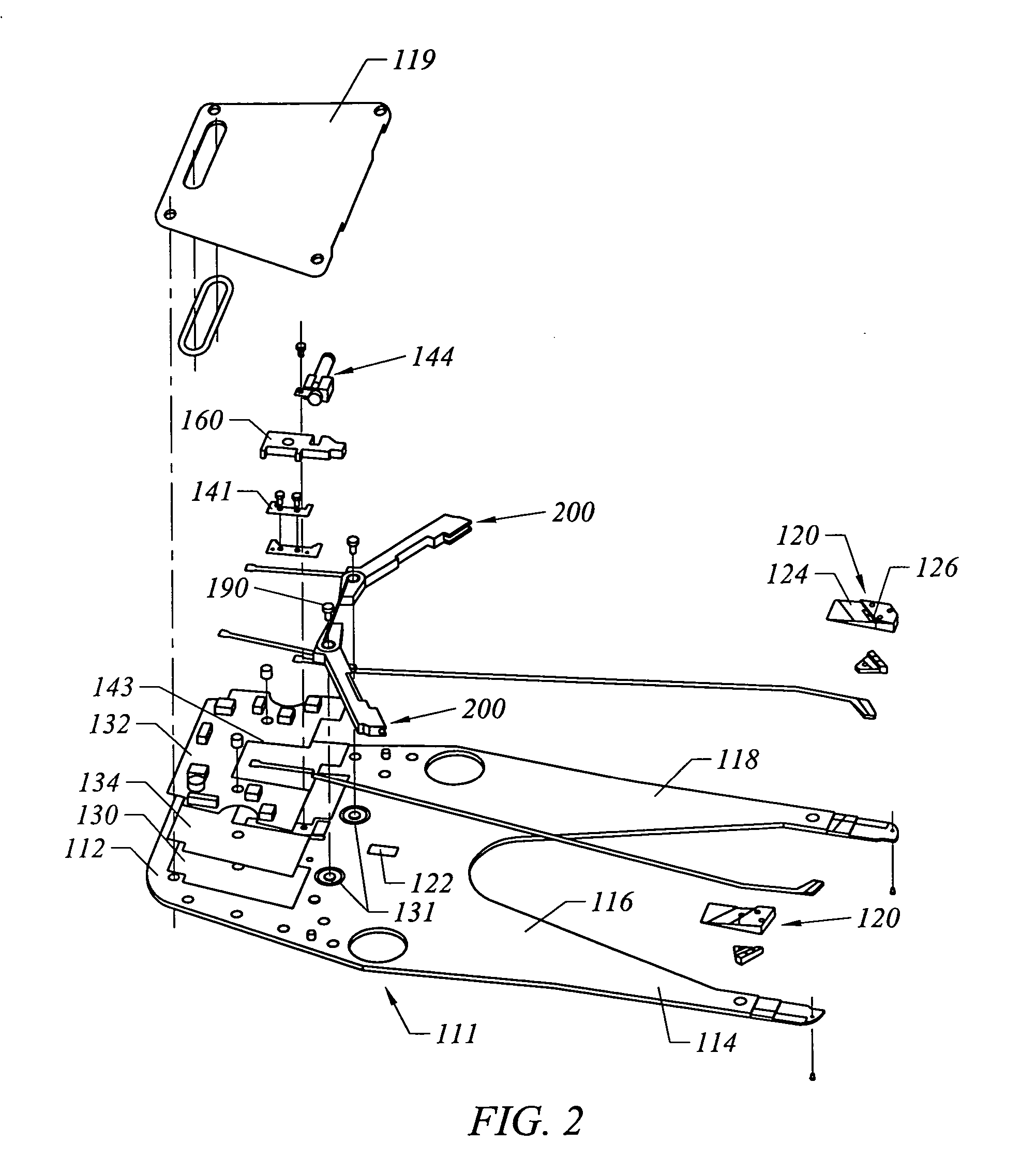

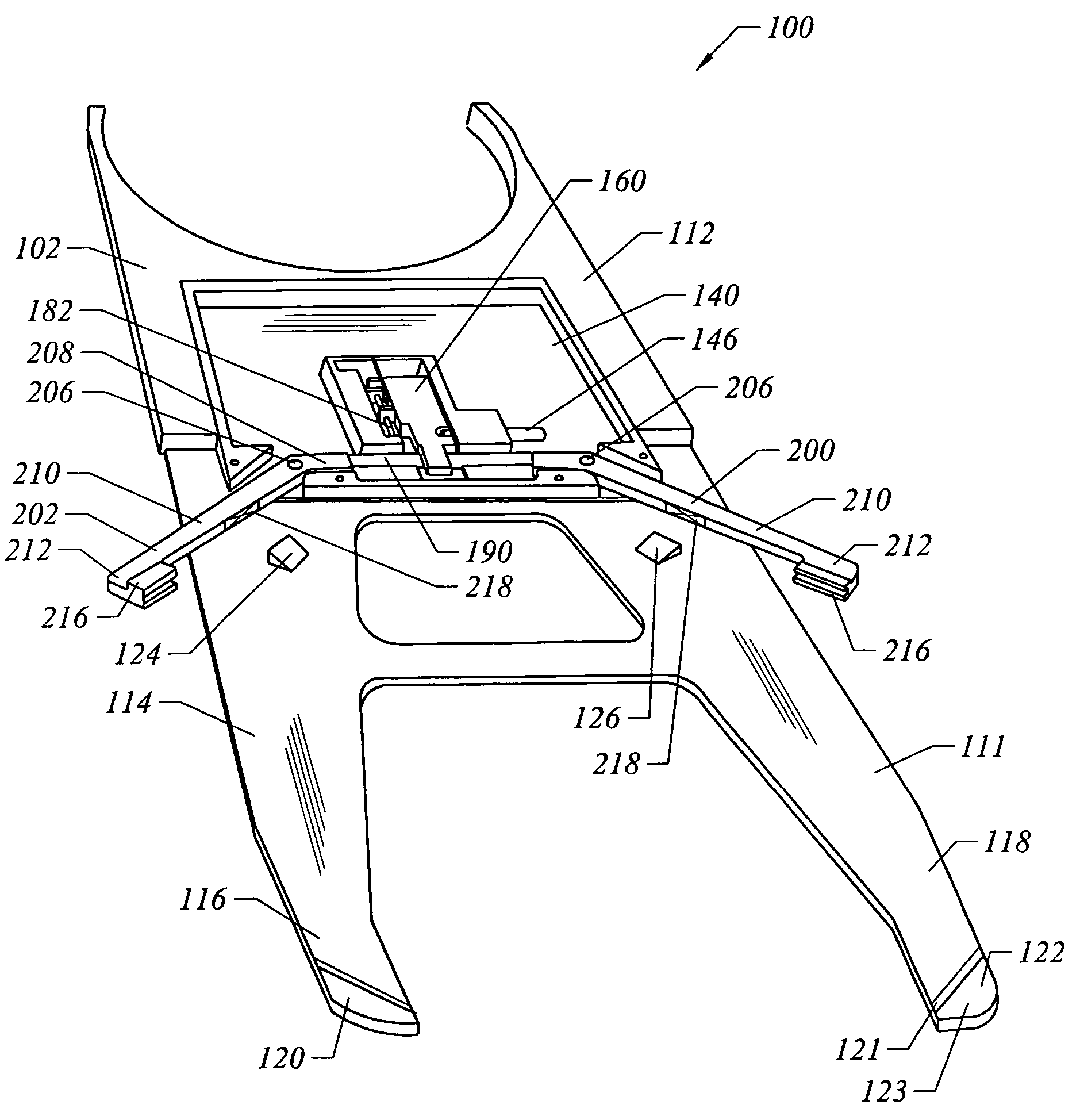

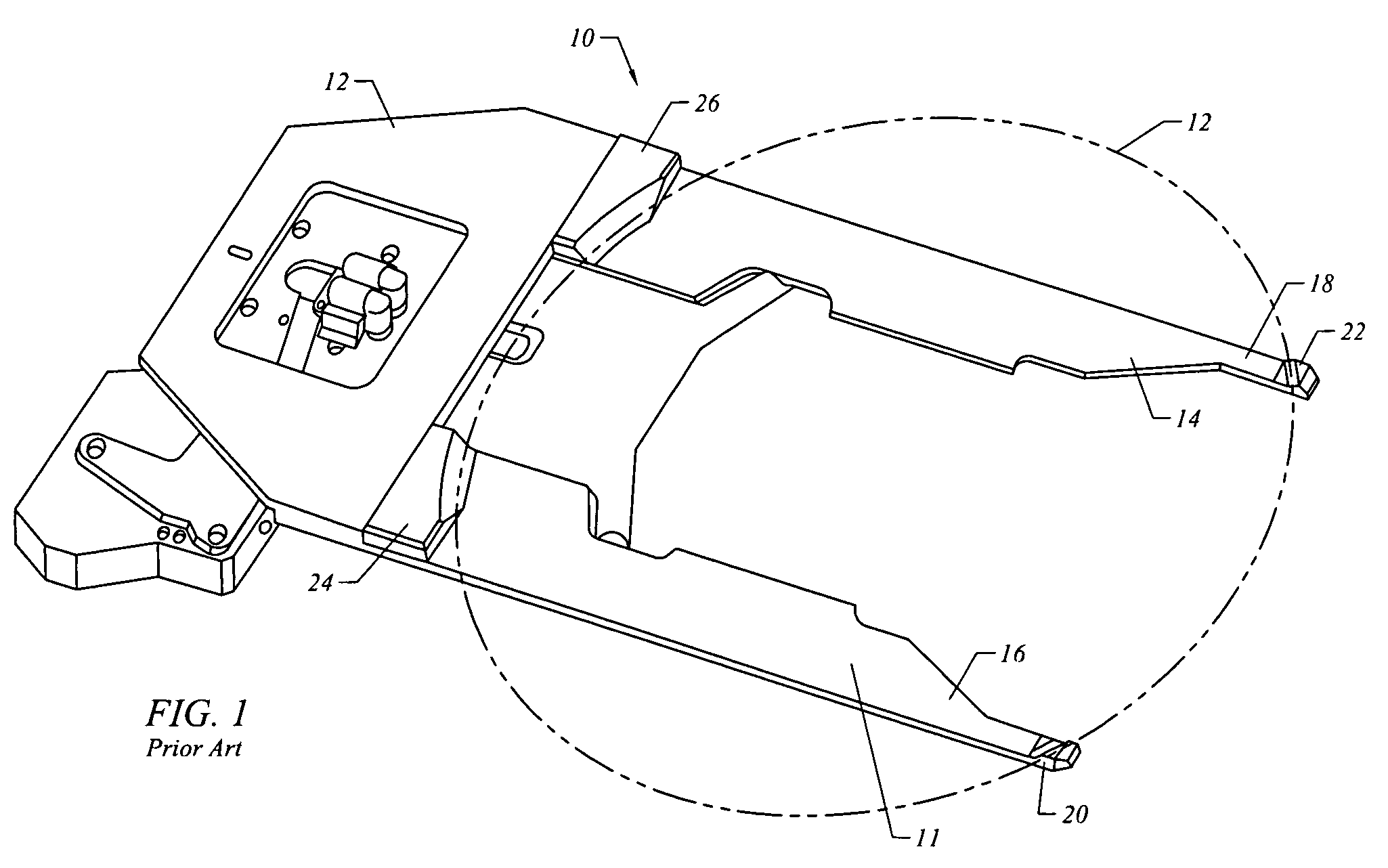

Active edge gripping end effector

ActiveUS20050017529A1Minimize impactReduces large impact forceGripping headsSemiconductor/solid-state device manufacturingActive edgeEngineering

The present invention generally relates to an end effector that utilizes a gripping mechanism to grip a peripheral edge of the wafer and secure the wafer to the end effector. In one embodiment, the gripping mechanism includes a pair of gripper arms that pivot between a wafer-loading position and a wafer-engaging position. In another embodiment, an active plunger moves linearly between the wafer-loading and wafer-engaging positions. Both the gripper arms and the plunger device are driven by a motor assembly. A force feedback system monitors the force the gripping mechanism exerts on the wafer and, based on the amount of force, controls the operation of the motor assembly to dynamically adjust the position of the gripping mechanism.

Owner:BOOKS AUTOMATION US LLC

Active edge gripping and effector

InactiveUS7300082B2Good centering effectMinimize slidingGripping headsSemiconductor/solid-state device manufacturingActive edgeSystem monitor

Owner:BOOKS AUTOMATION US LLC

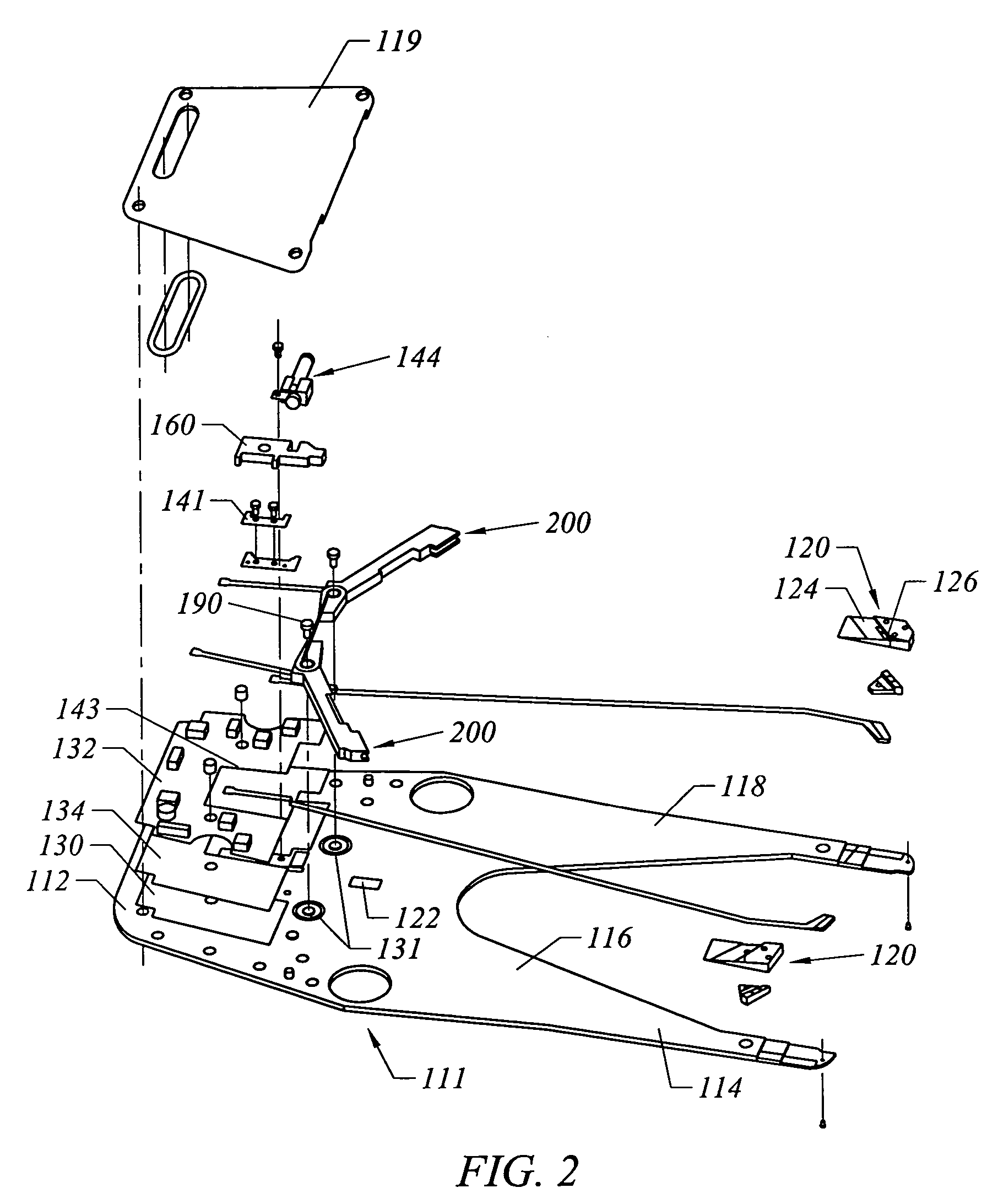

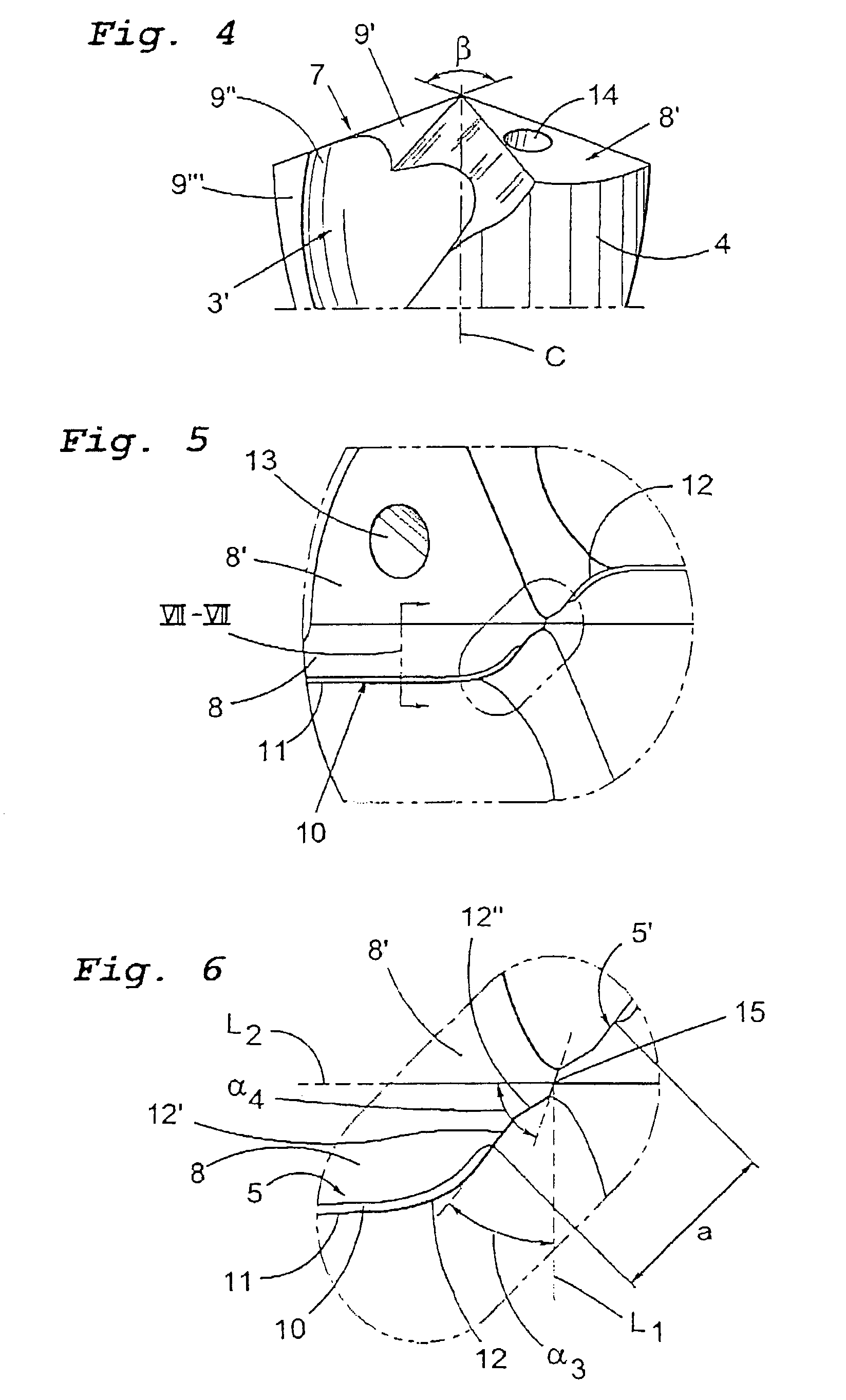

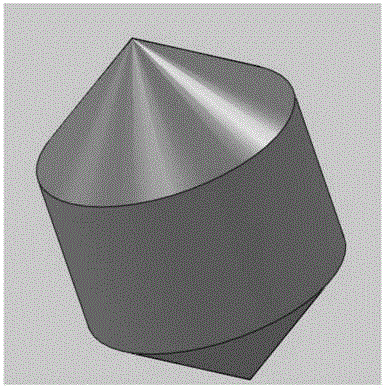

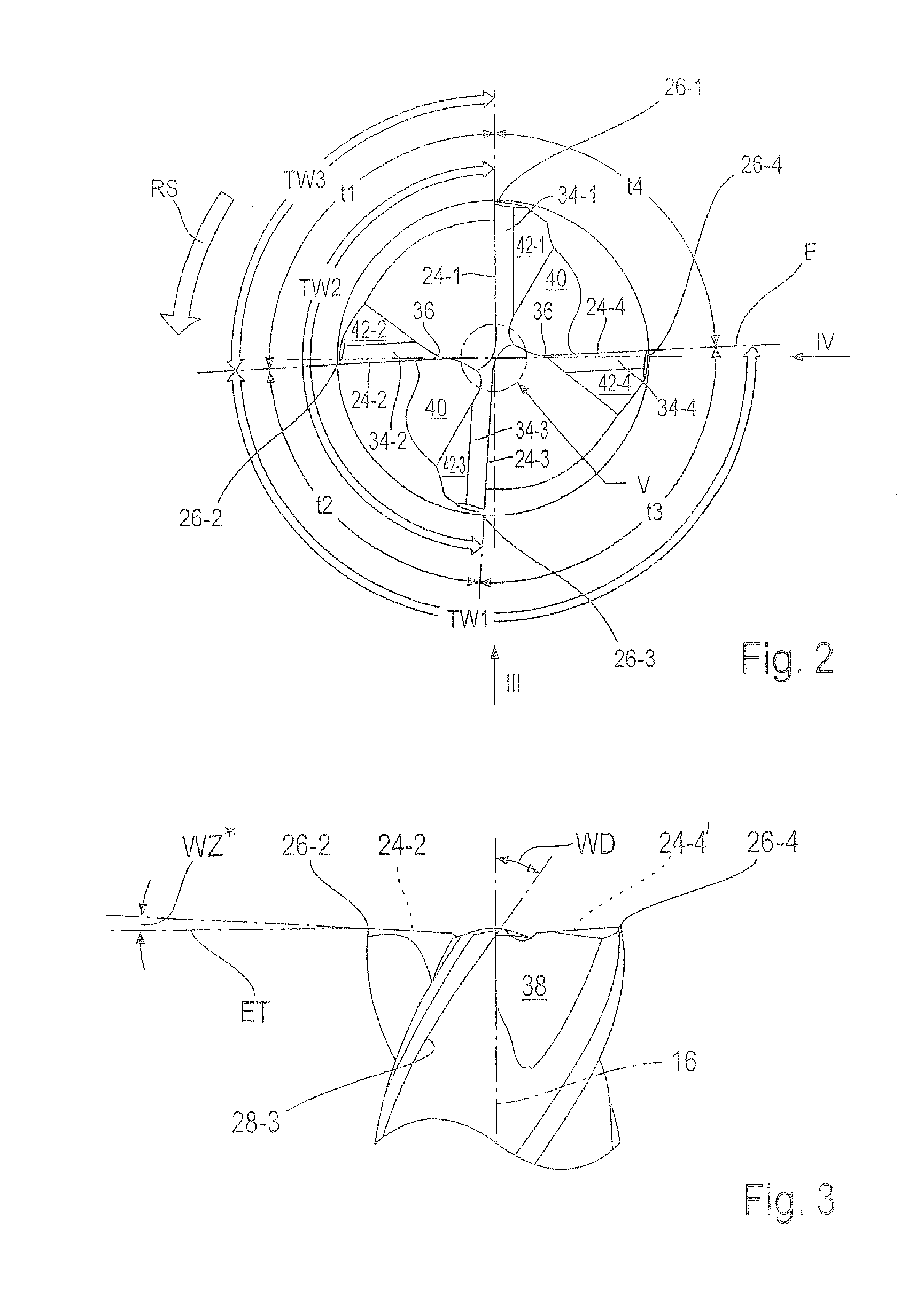

Drilling tool for holemaking in metallic workpieces

ActiveUS7241085B2Improve centering abilityGood centering abilityWood turning toolsTransportation and packagingFluteLevel line

A drill comprises a shaft with chip conveying flutes and a drill head at its forward end with at least two cutting inserts. Each cutting insert is provided with at least one cutting edge which is delimited between a chipbreaking surface and first relief surface and which includes an outer straight edge. In the proximity of the center axis of the shaft, a curved cutting edge section is provided, to which there is connected an adjacent enforcement bevel. The cutting edge is in direct proximity to a center axis, and is terminated by a chisel edge between the cutting inserts to serve as a centering core portion. The curved cutting edge section is inwardly followed by a primary straight portion without an adjacent enforcement bevel in a direction that is oriented at an angle of between approximately 40–50° in relation to a horizontal line that extends through the center axis of the drill.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

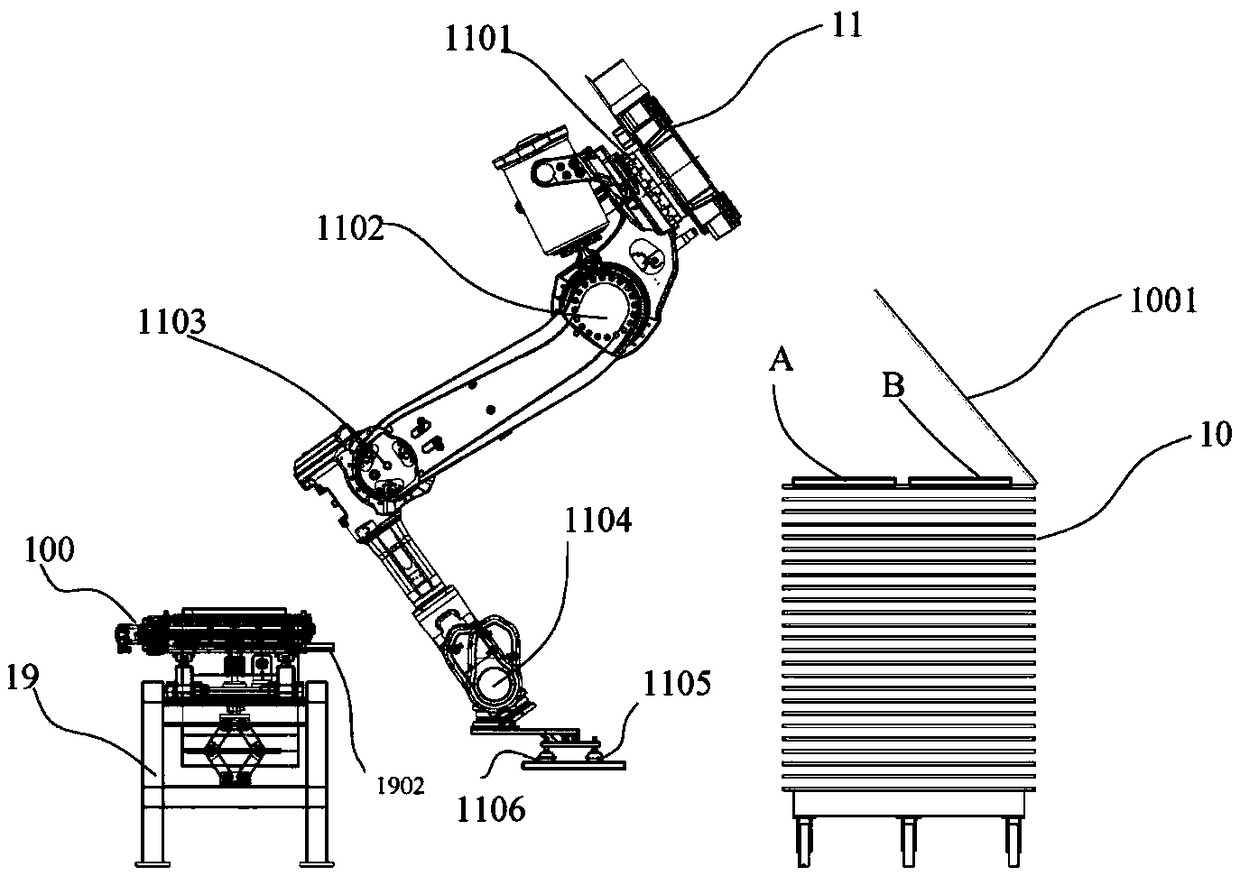

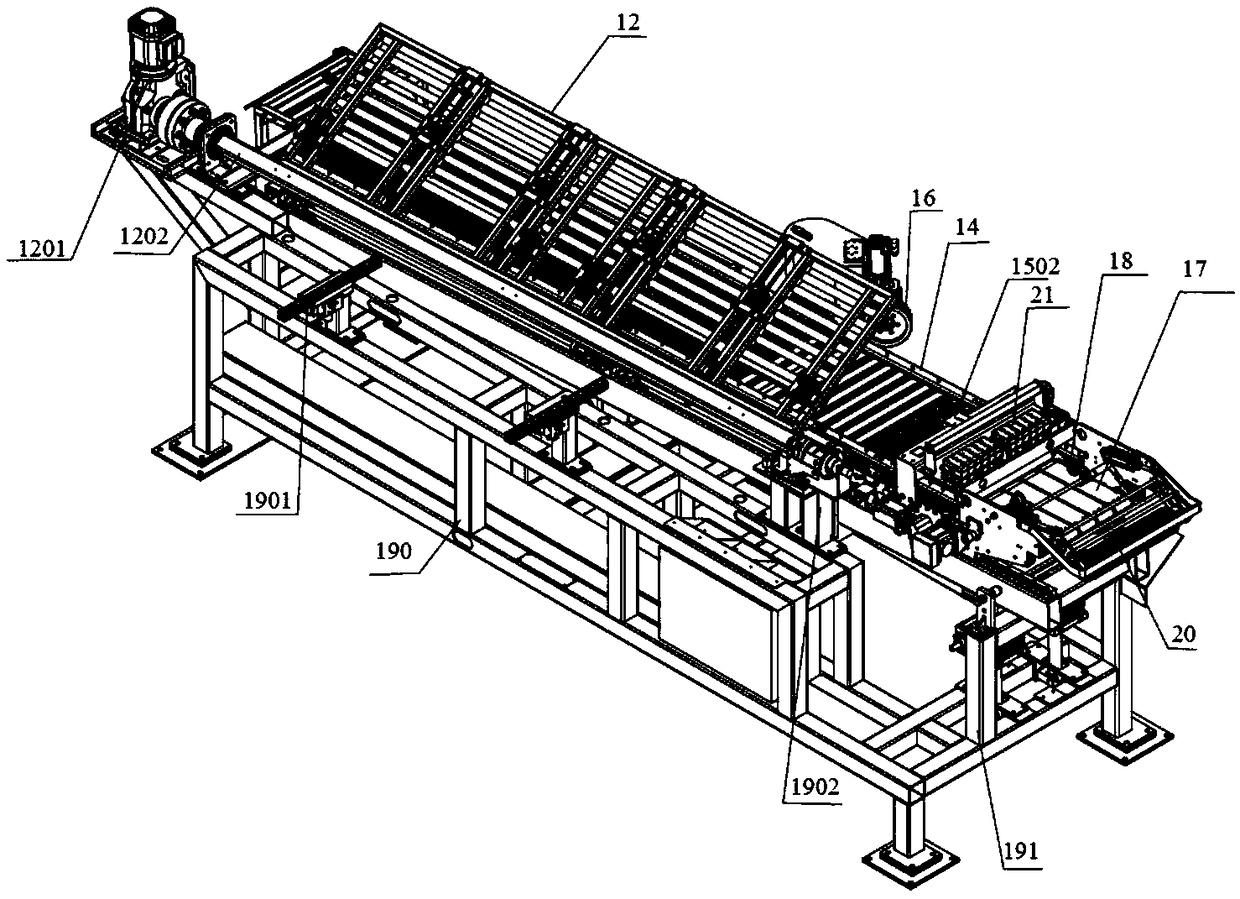

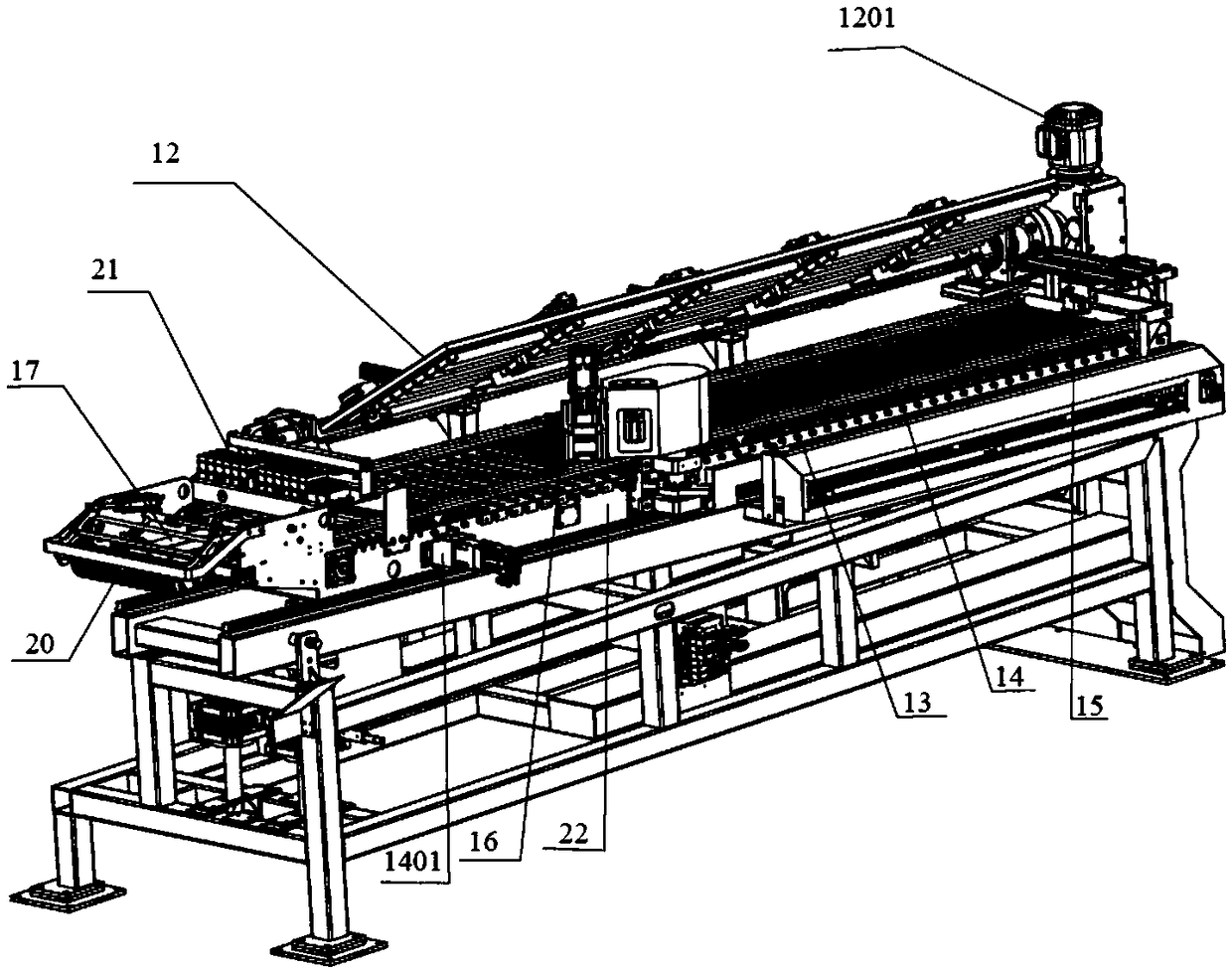

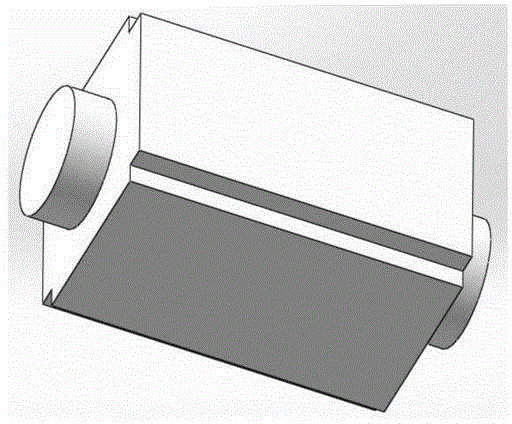

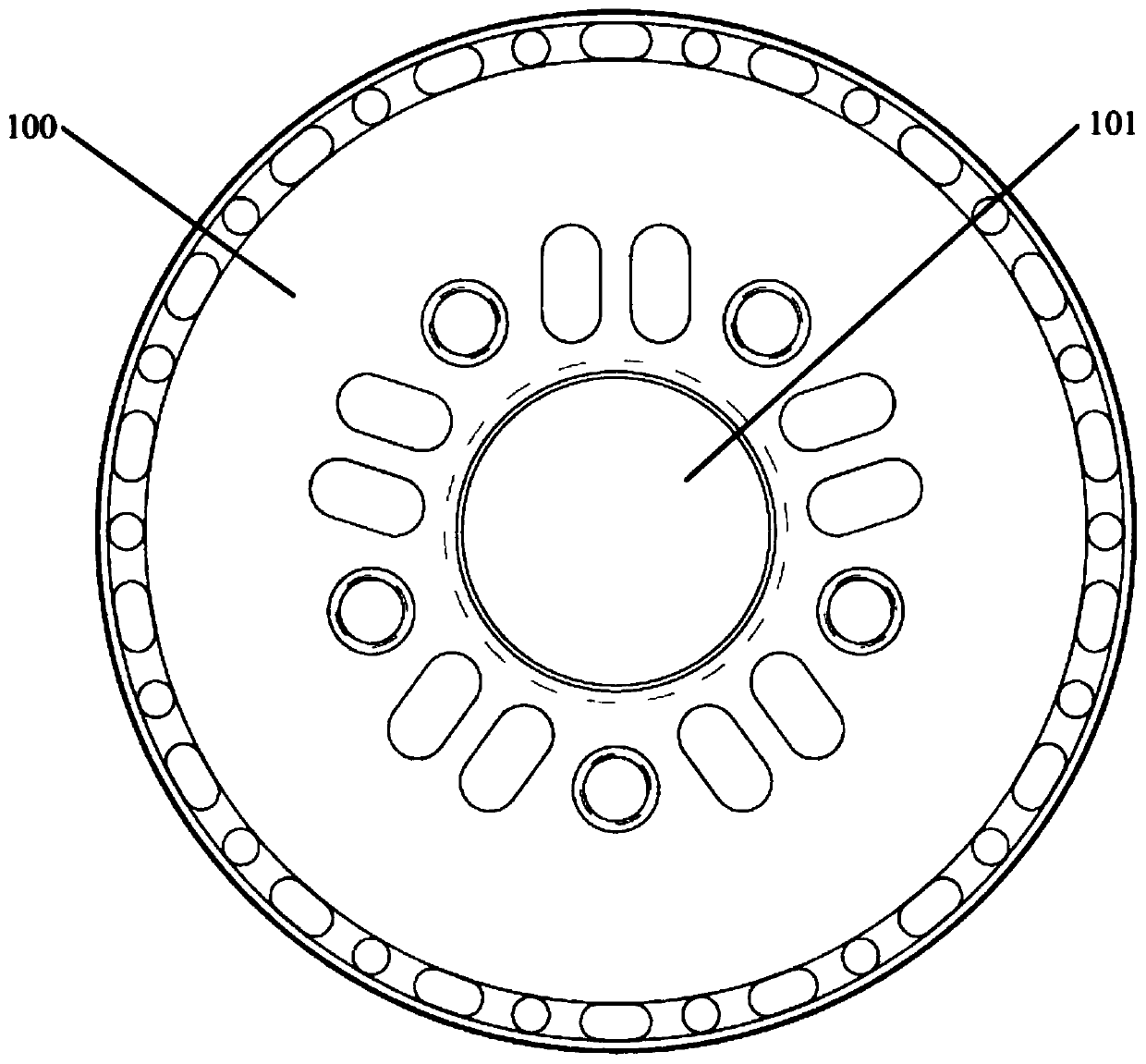

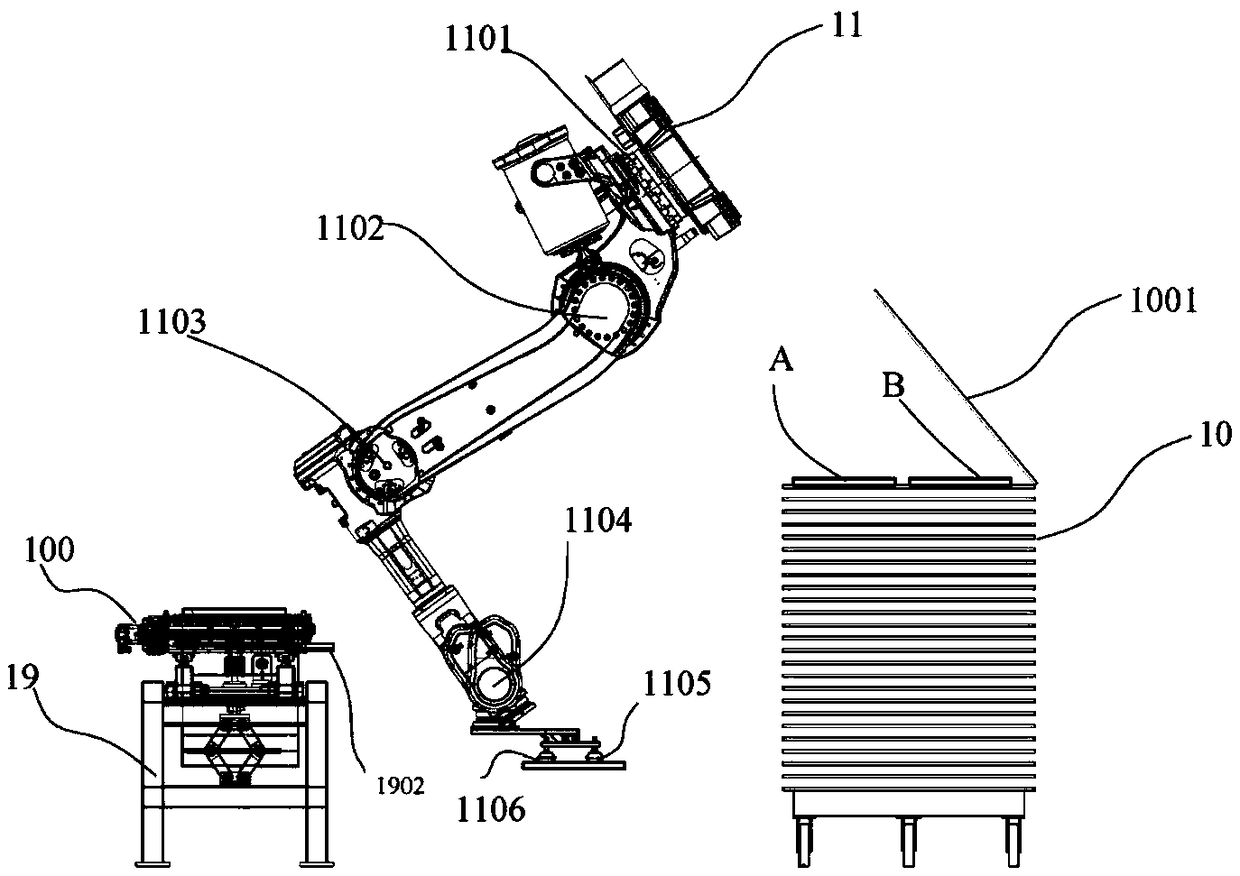

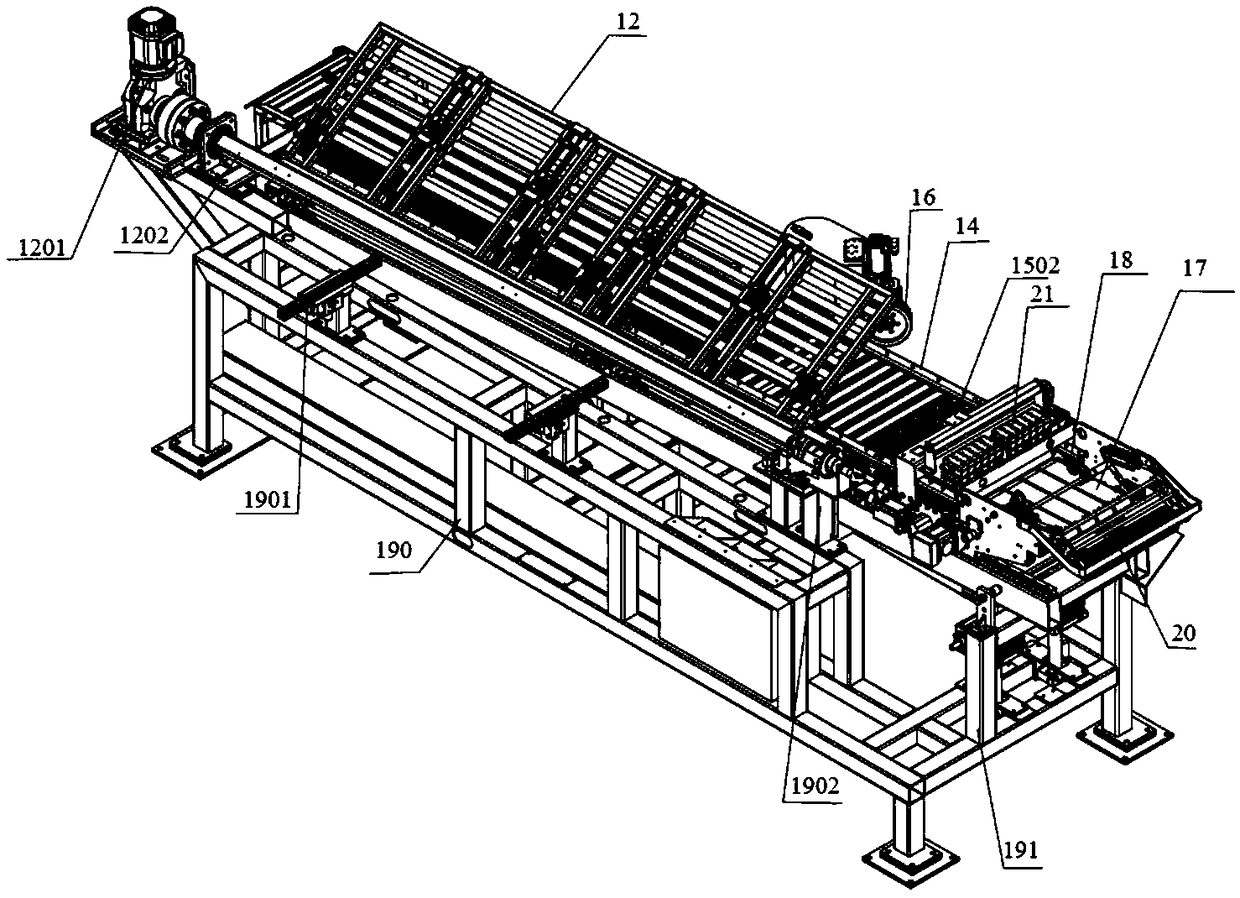

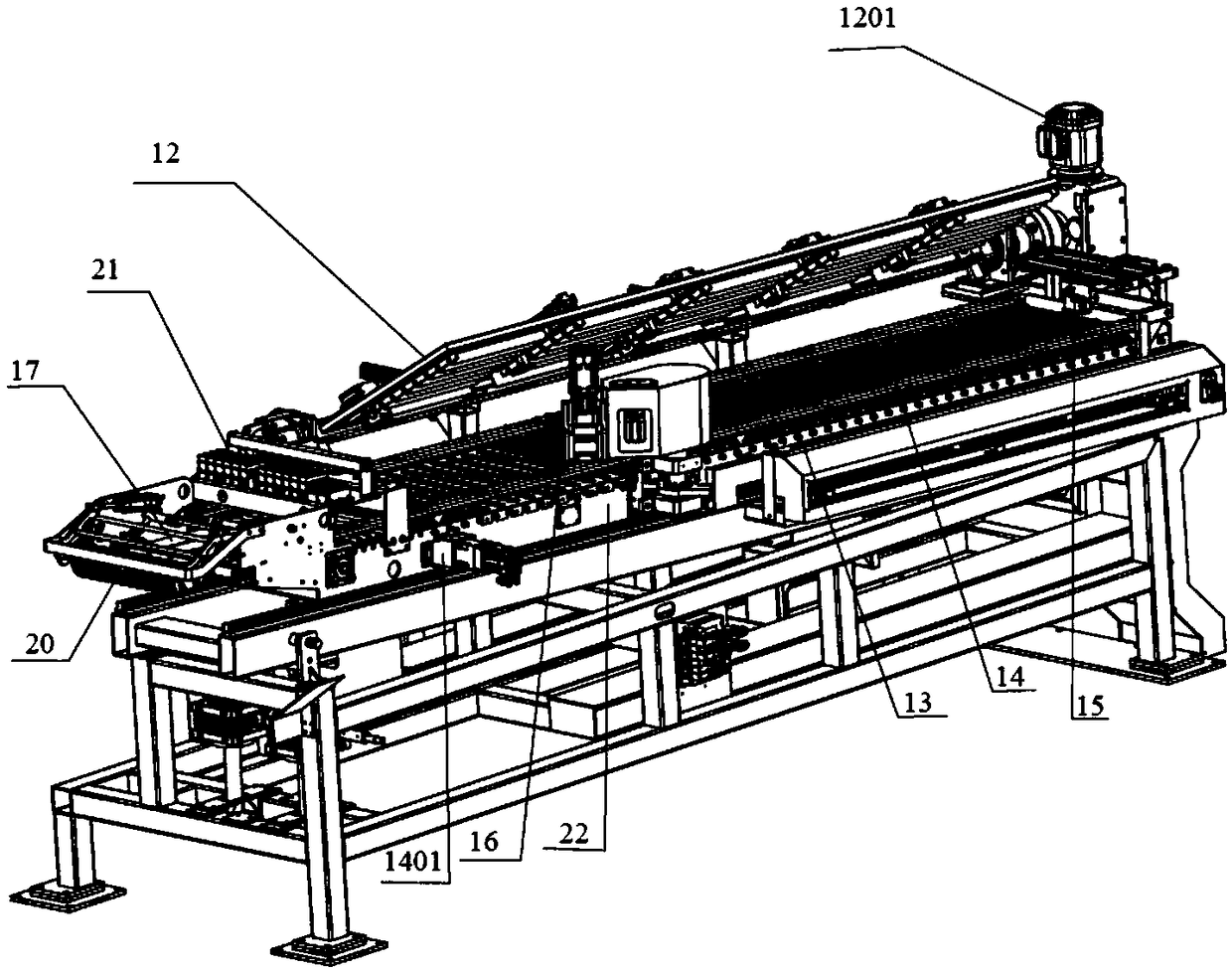

Automatic tire tread supply system

ActiveCN108790229AGood centering effectThe test result is accuratePlastic recyclingTyresTreadAutomotive engineering

The invention provides an automatic tire tread supply system. The automatic tire tread supply system comprises a shutter trolley, a grabbing device, a supply device and a PLC. Tire treads on the shutter trolley are transferred to the supply device through the grabbing device and then attached to a belt bundle drum, and the shutter trolley, the grabbing device and the supply device are in signal connection with the PLC.

Owner:HANGZHOU CHAOYANG RUBBER

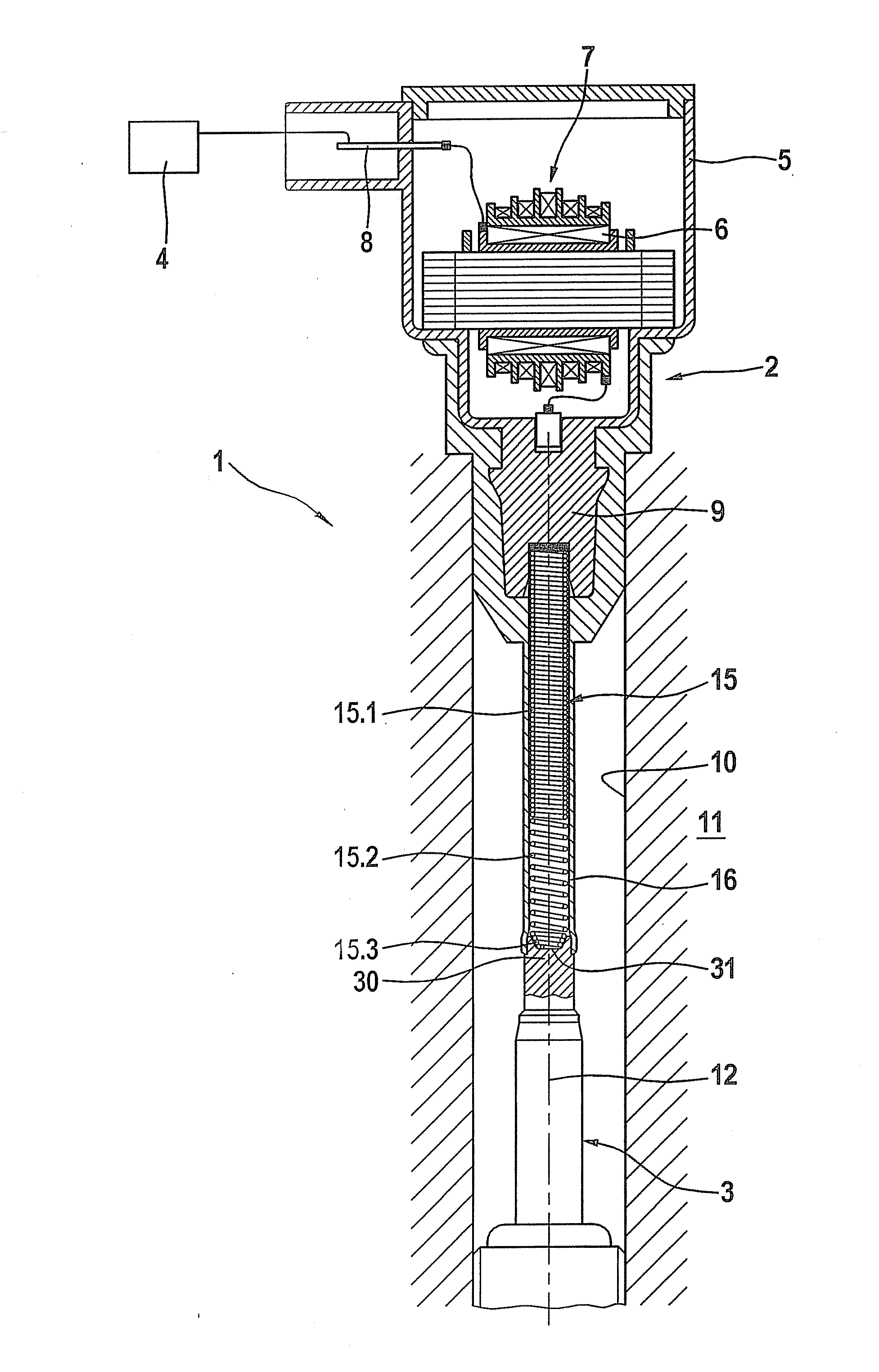

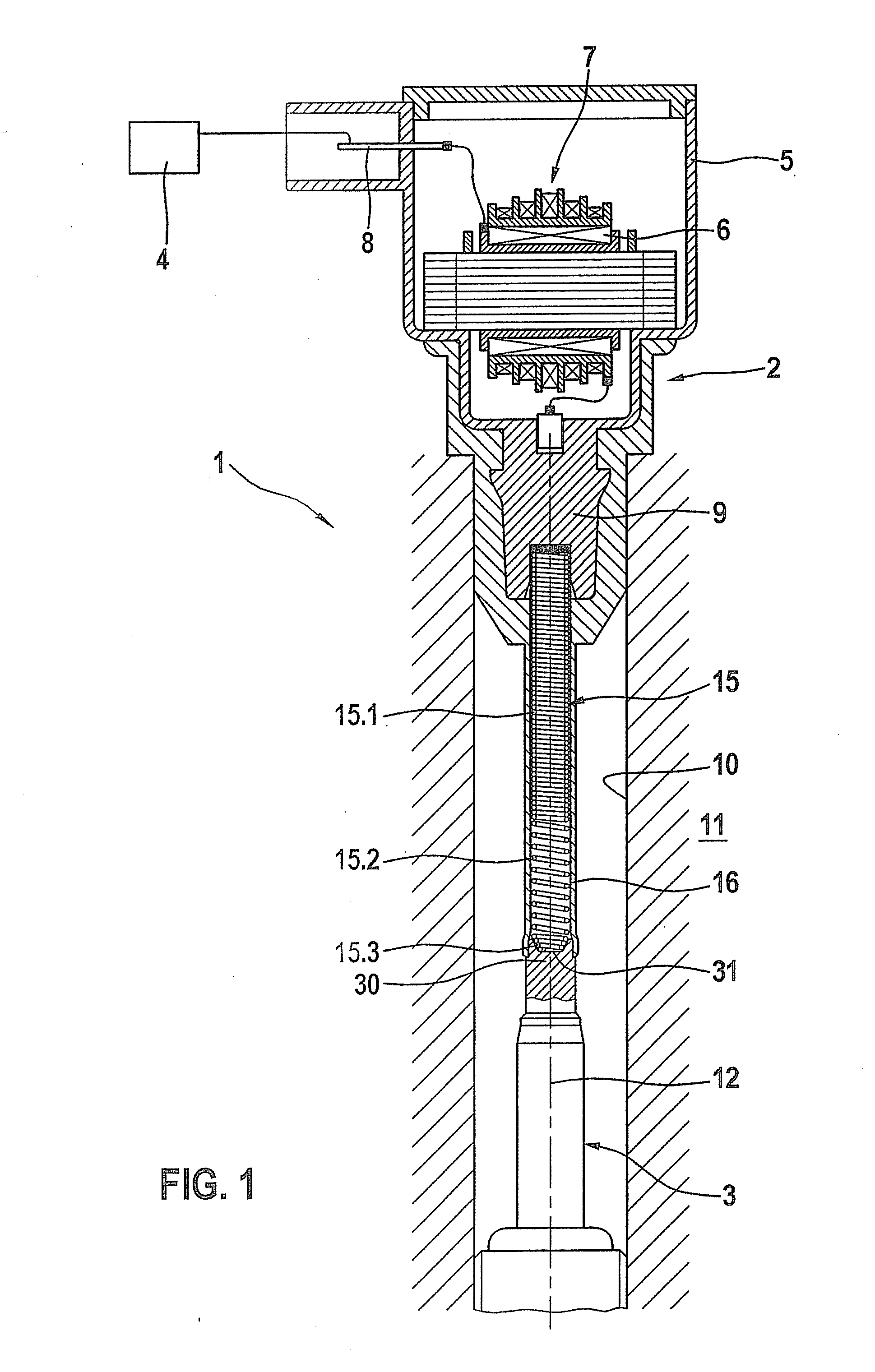

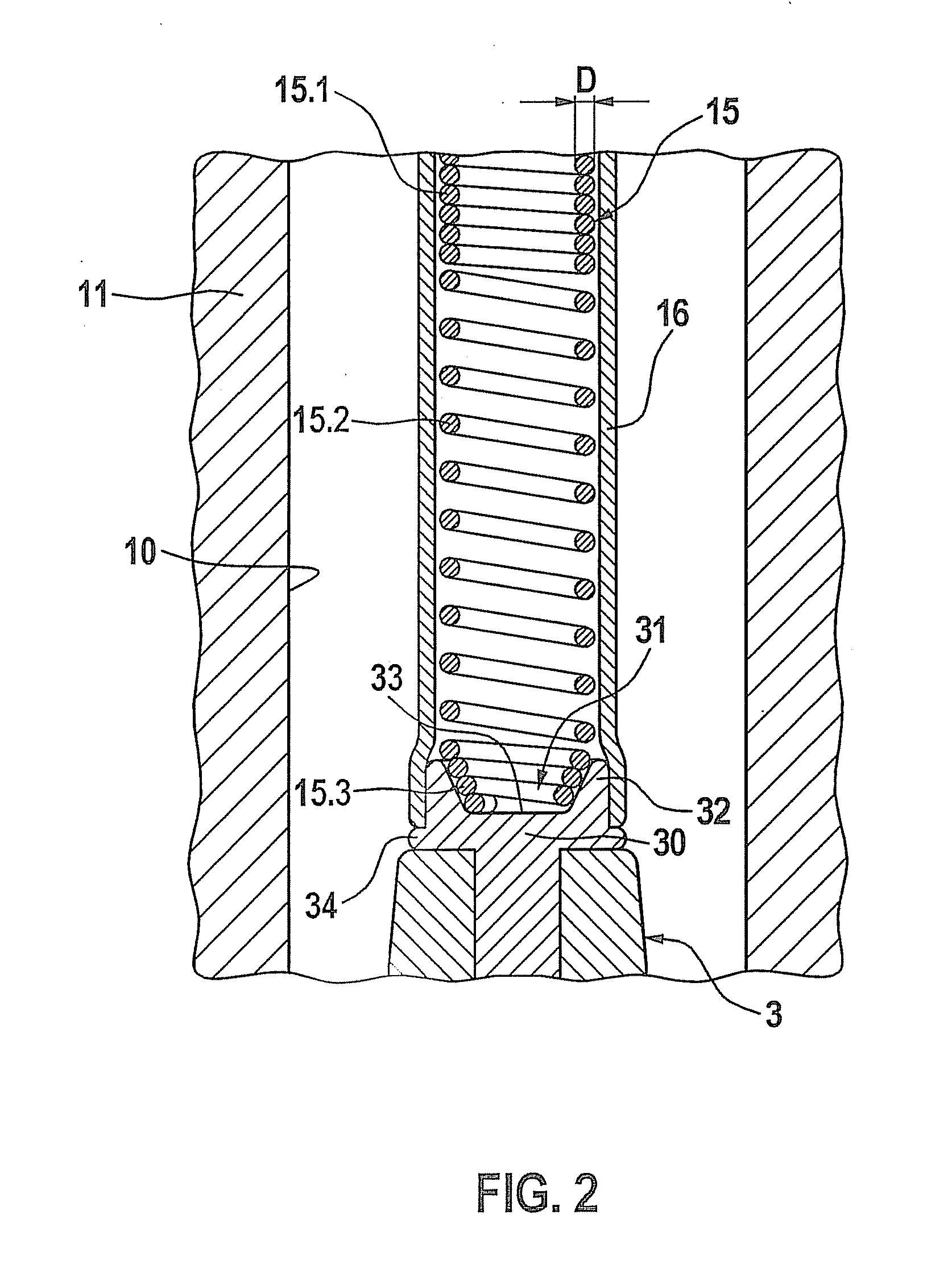

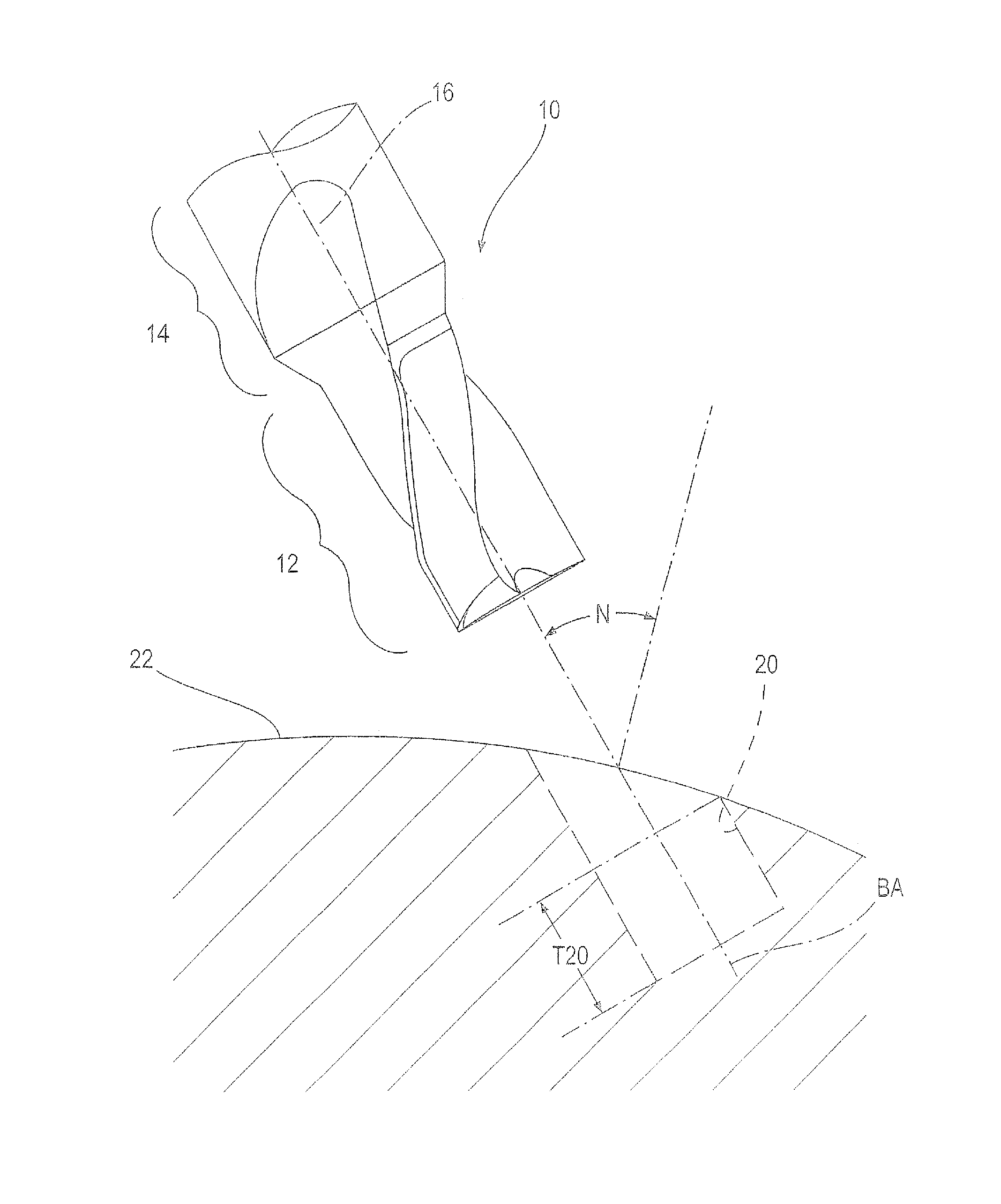

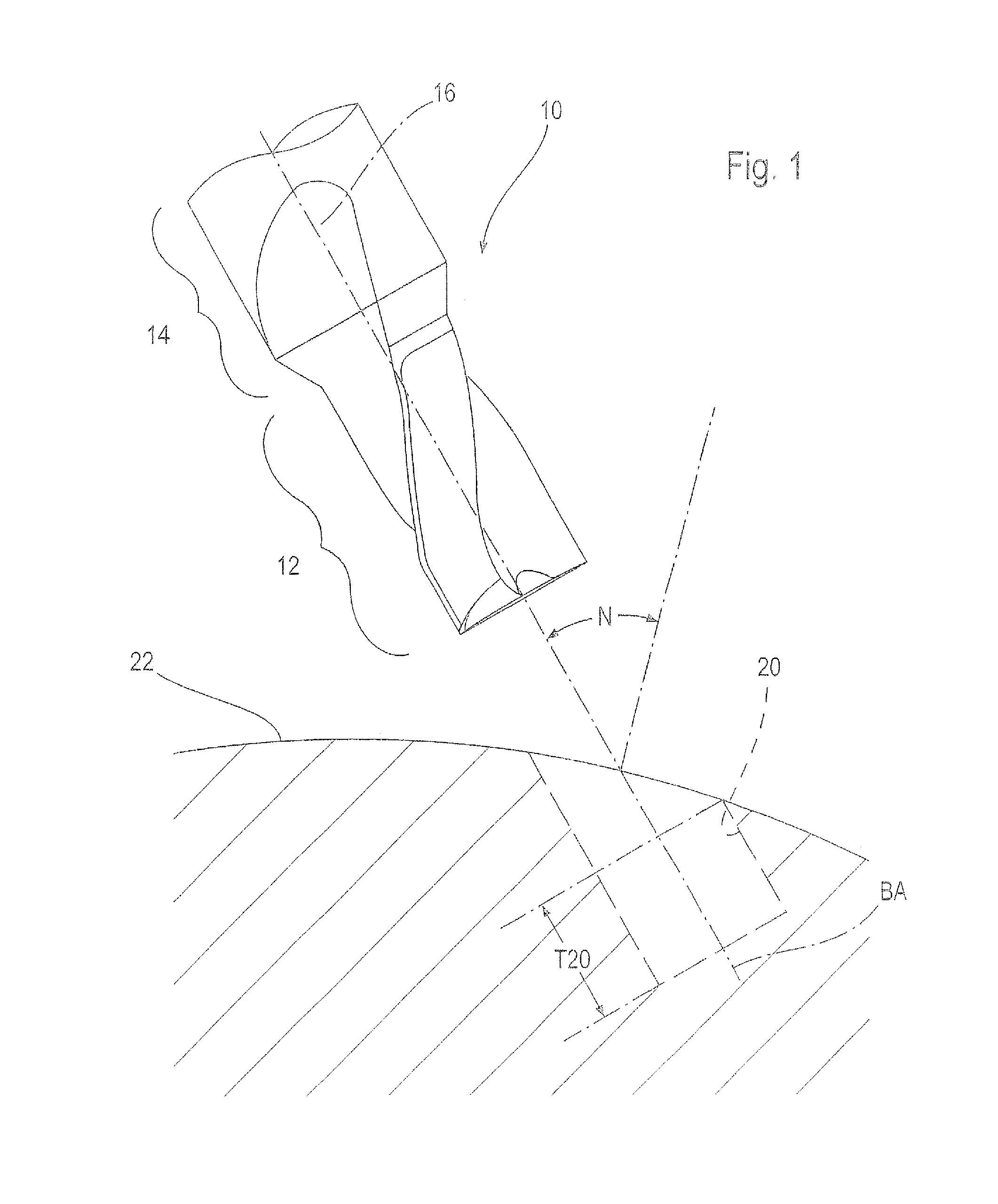

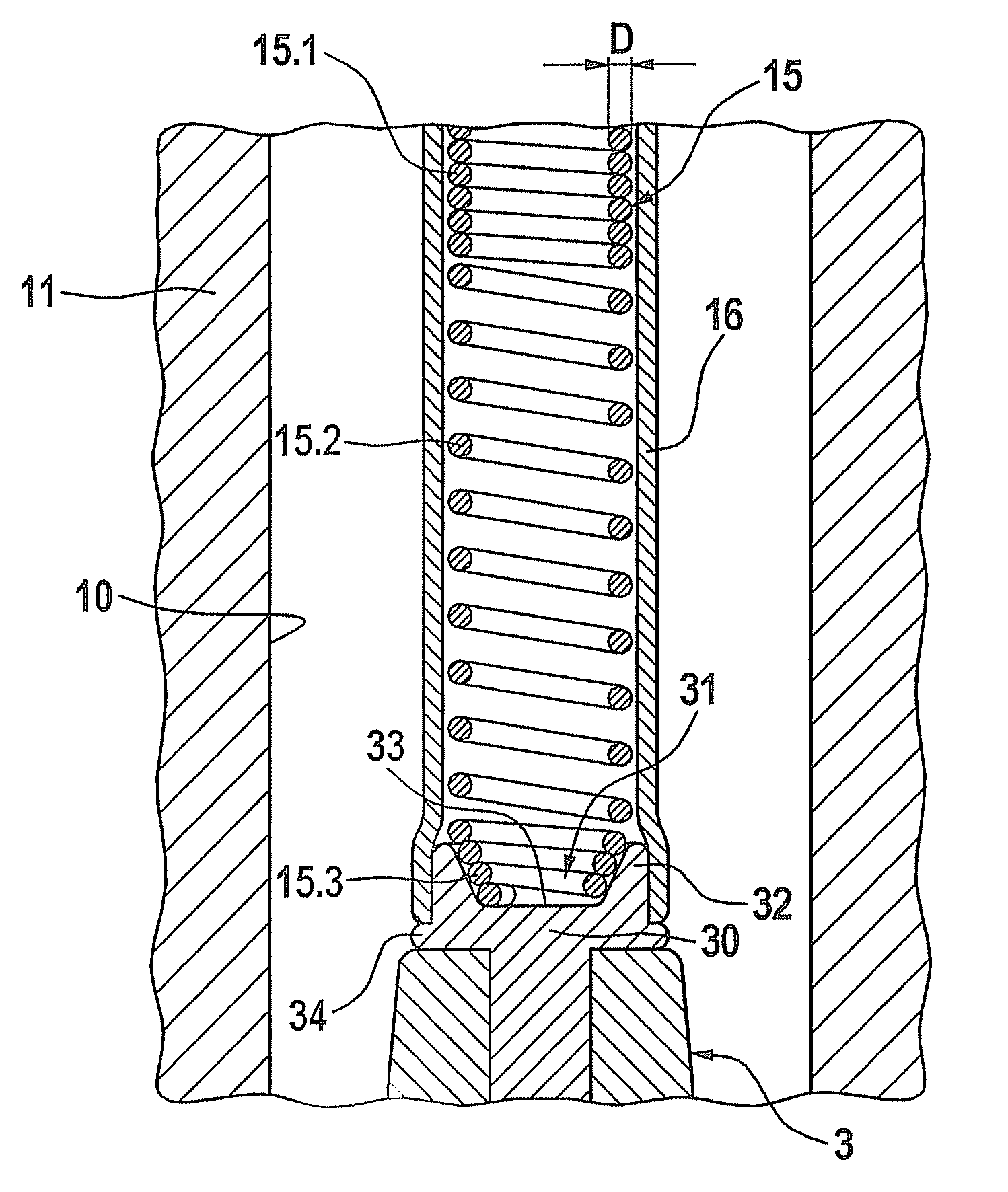

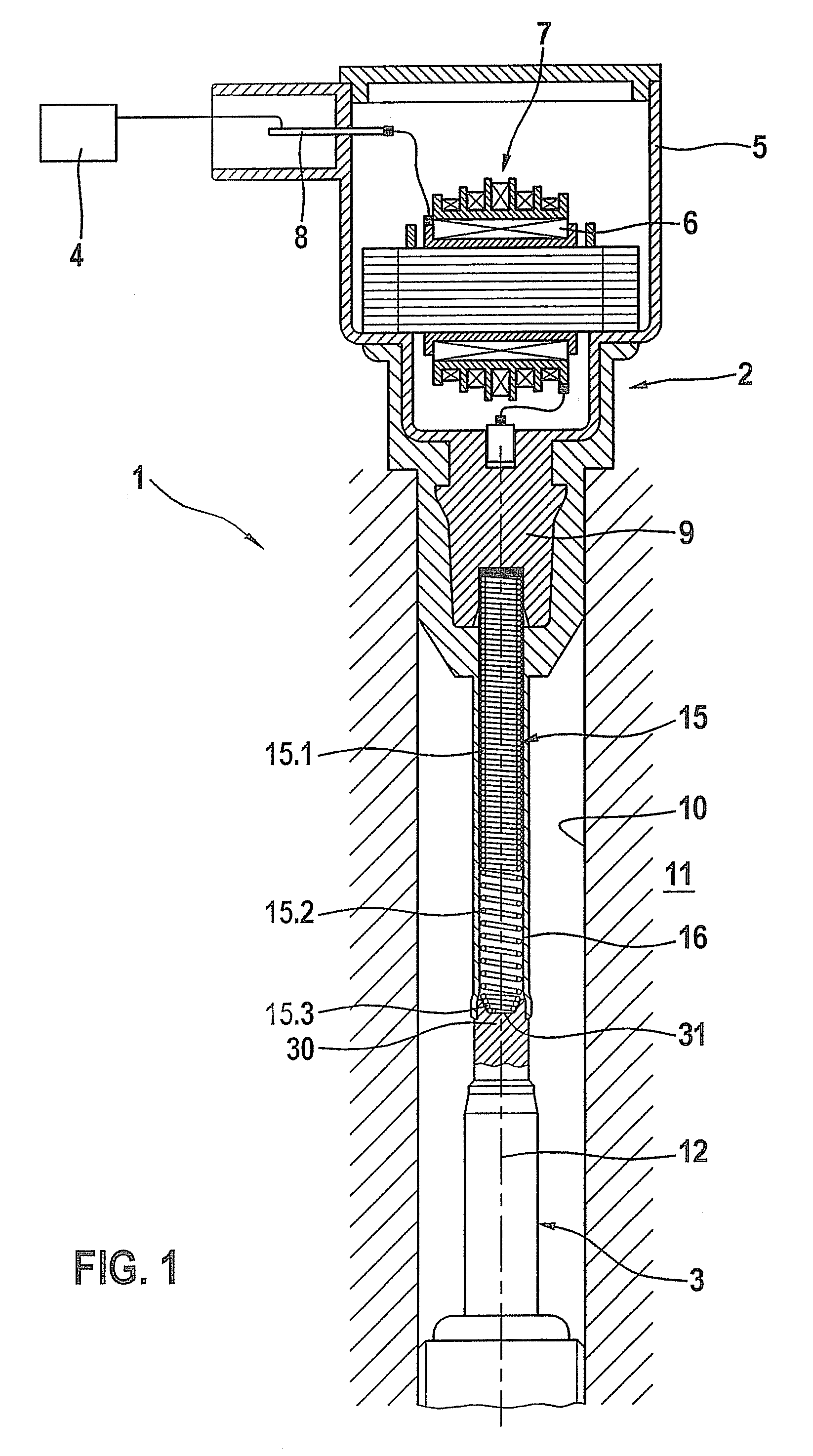

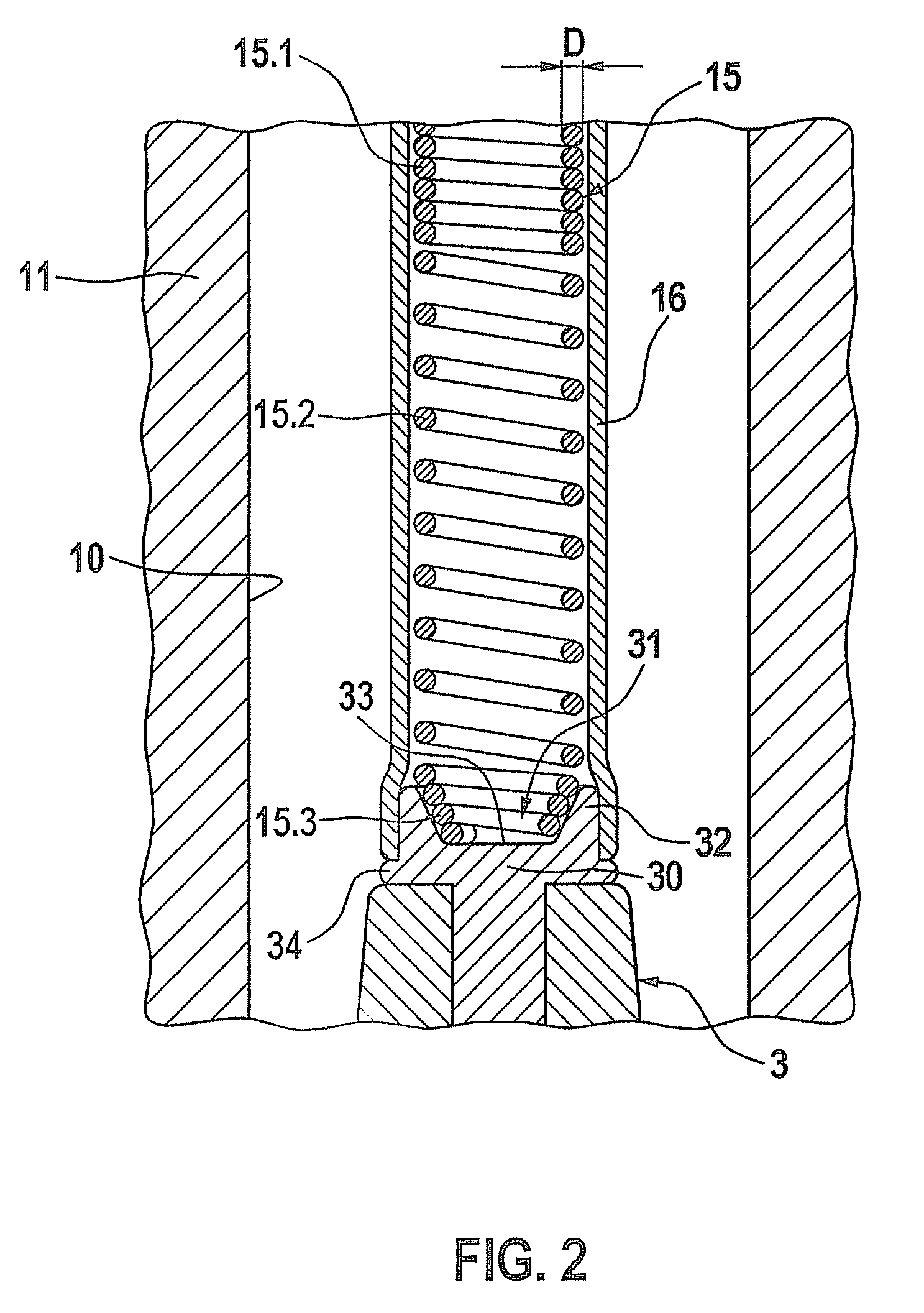

Ignition coil, spark plug, and ignition set-up including an ignition coil and spark plug,

In an ignition coil having a high-voltage terminal and a spring for electrically connecting the high-voltage terminal to a spark plug, a contact segment of the spring, which is directed towards the spark plug, has an outer circumference that is reduced in comparison with an outer circumference of further segments of the spring. The spark plug has a contact region for contacting with the spring of the ignition coil, which contact region has a recess surrounded by a closed, annular wall region for receiving the contact segment of the spring of the ignition coil.

Owner:ROBERT BOSCH GMBH

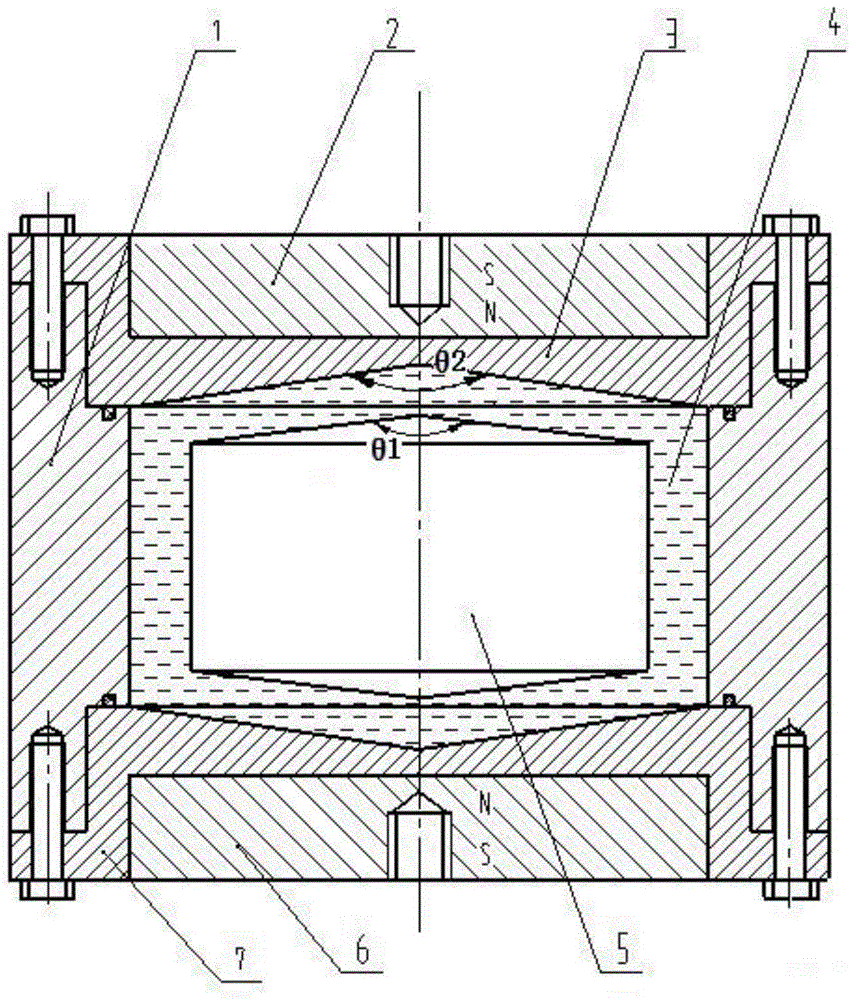

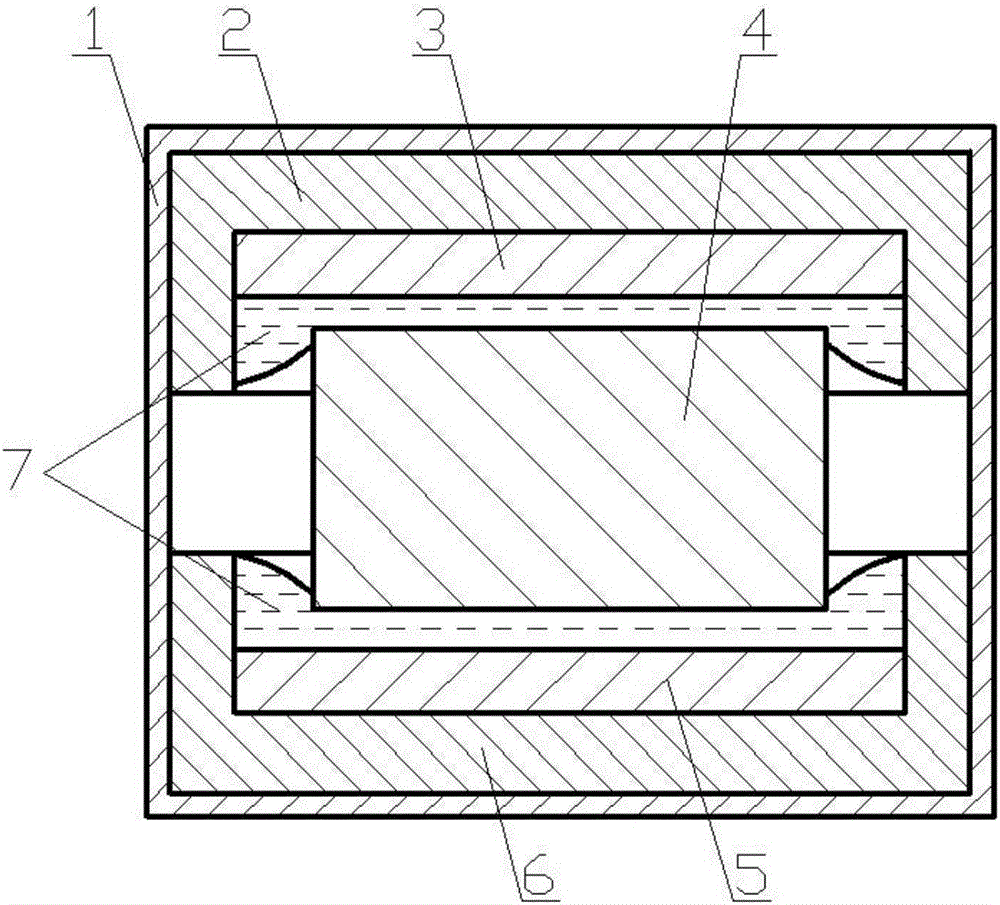

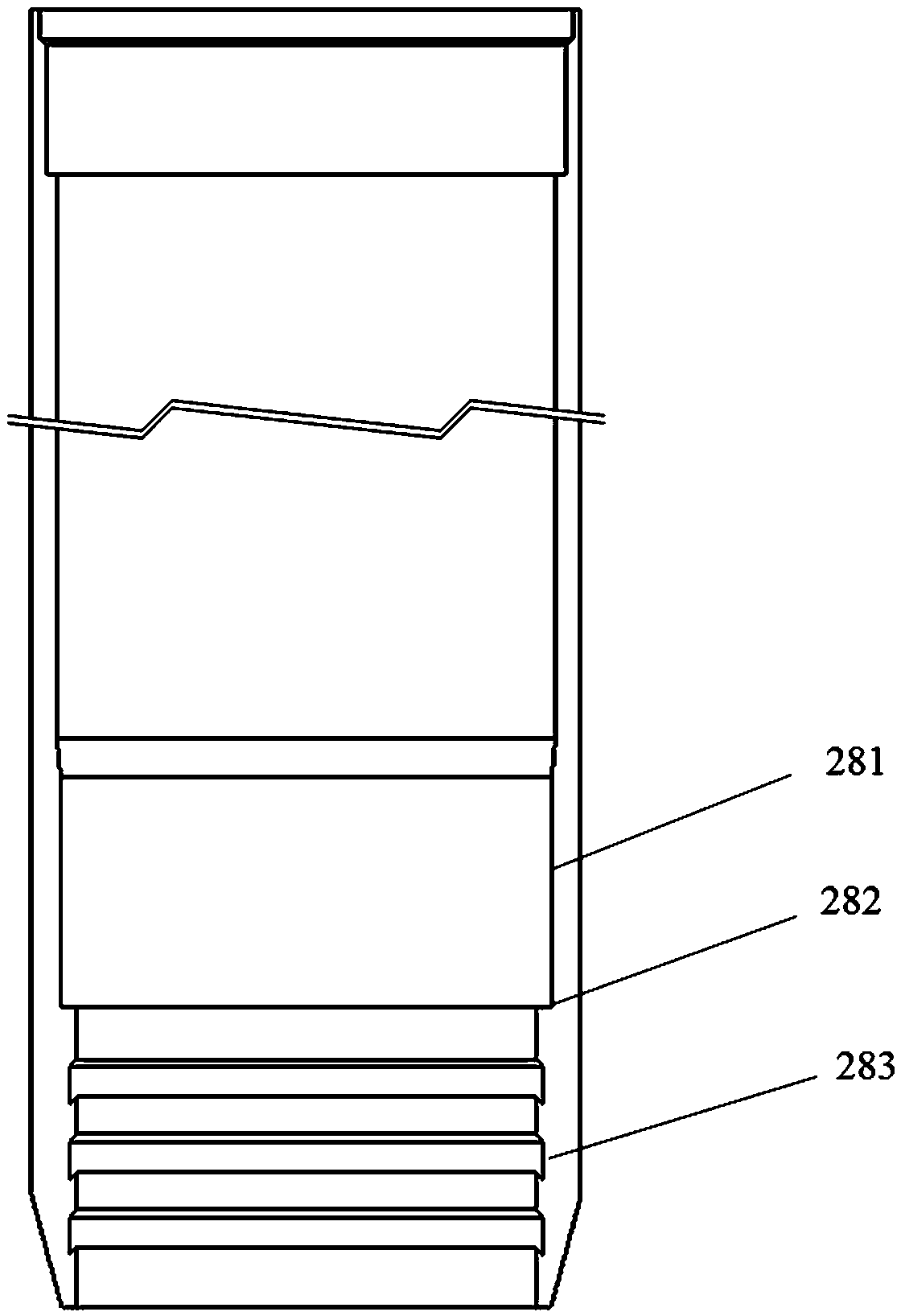

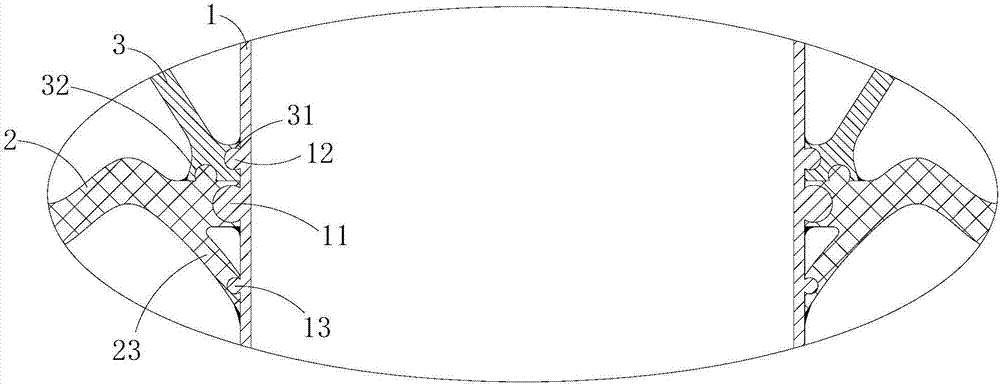

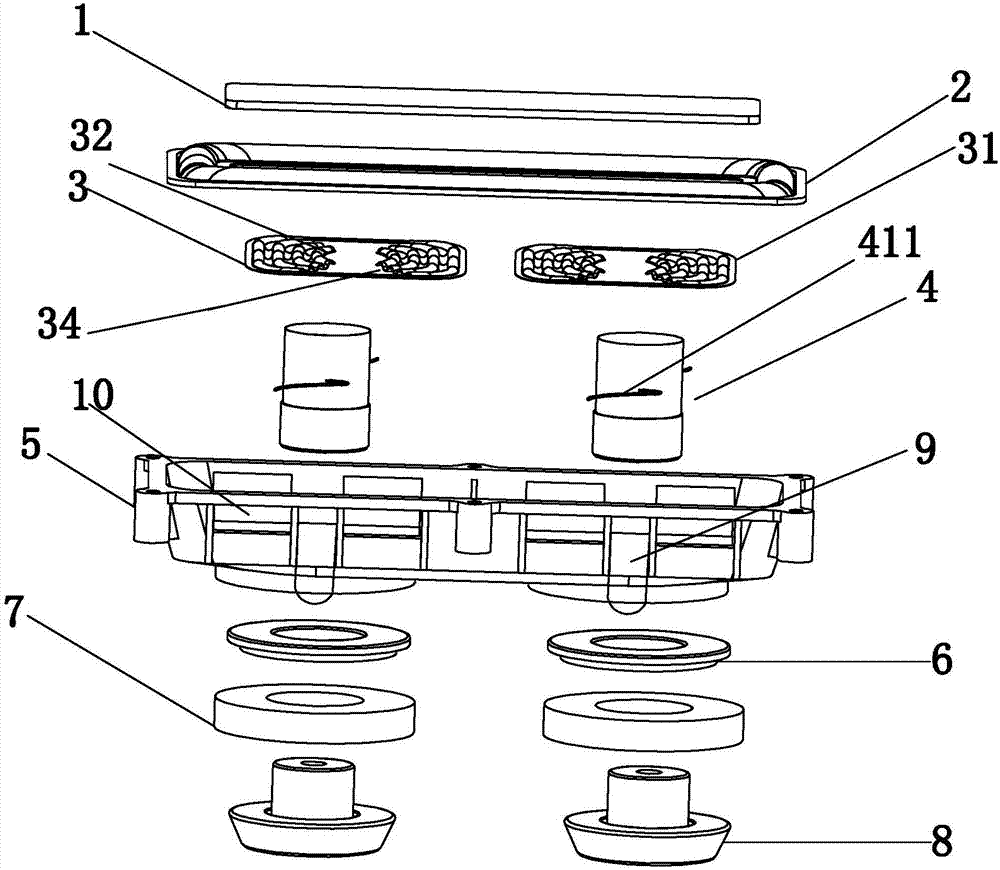

Double-tapered-angle magnetic liquid shock absorber on basis of first-order buoyancy principle

InactiveCN104895983AEasy to fillProtects against impact chipping or looseningMagnetic springsEnergy absorbingMagnetic liquids

The invention discloses a double-tapered-angle magnetic liquid shock absorber on the basis of a first-order buoyancy principle, and belongs to the field of vibration of mechanical engineering. The problem that due to multiple structural problems, an existing magnetic liquid damping shock absorber cannot be applied to the engineering practice is successfully solved. The double-tapered-angle magnetic liquid shock absorber comprises a shell (1), a first permanent magnet (2), an upper end cover (3), magnetic liquid (4), a mass block (5), a second permanent magnet (6) and a lower end cover (7). When the exterior vibrates, the mass block (5) moves in a cavity, and the magnetic liquid (4) flows in a gap between the inner hole wall of the shell (1) and the mass block (5), so that the energy is absorbed, and the aim of reducing the vibration is achieved; first-order buoyancy formed by the first permanent magnet (2) and the second permanent magnet (6) in the magnetic liquid enables a frequency difference to be formed between the mass block (5) and the shell (1); and the vibration reduction efficiency is maximized.

Owner:BEIJING JIAOTONG UNIV

First-order buoyancy magnetic liquid damping vibration absorber for magnetic shielding

InactiveCN106678255ALight in massGood centering effectSpringsNon-rotating vibration suppressionStructural ProblemMagnetic liquids

The invention discloses a first-order buoyancy magnetic liquid damping vibration absorber for magnetic shielding, and belongs to the field of mechanical engineering vibration. The problem that existing magnetic liquid damping vibration absorbers cannot be applied in engineering practice due to various structural problems is successfully solved. The first-order buoyancy magnetic liquid damping vibration absorber comprises a shell (1), an upper shielding cover (2), an upper permanent magnet (3), a mass block (4), a lower permanent magnet (5), a lower shielding cove (6) and magnetic liquid (7). When external vibration is produced, the mass block (4) moves in the upper shielding cover and the lower shielding cover, the magnetic liquid (7) flows in the gap between the upper and lower permanent magnets and the mass block (4), and therefore energy is absorbed to achieve the vibration absorption purpose; and a frequency difference is formed between the mass block (4) and the shell (1) due to first-order buoyancy formed by the upper permanent magnet (3) and the lower permanent magnet (5) inside the magnetic liquid (7), and the vibration absorption efficiency reaches the maximum.

Owner:BEIJING JIAOTONG UNIV

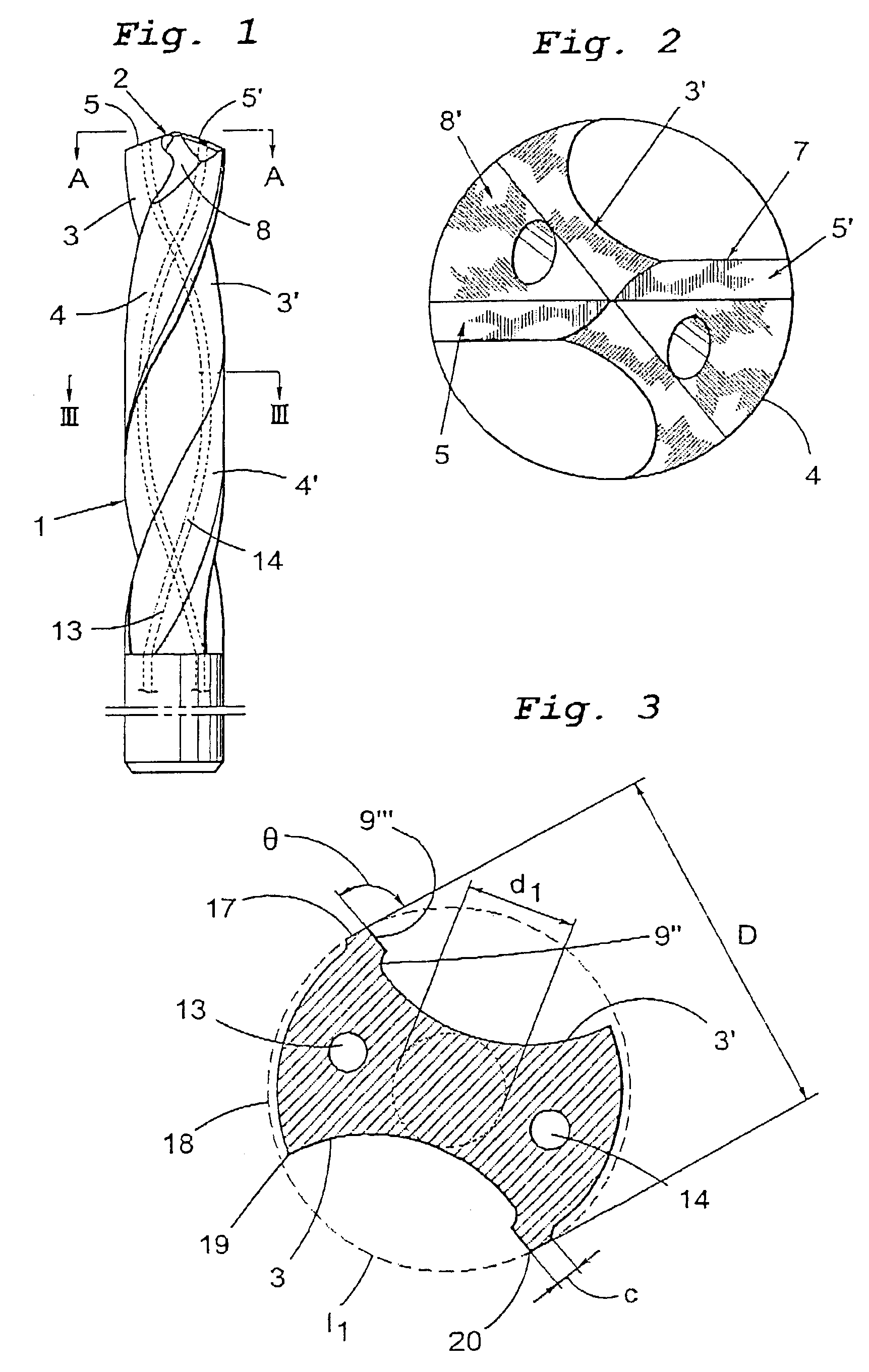

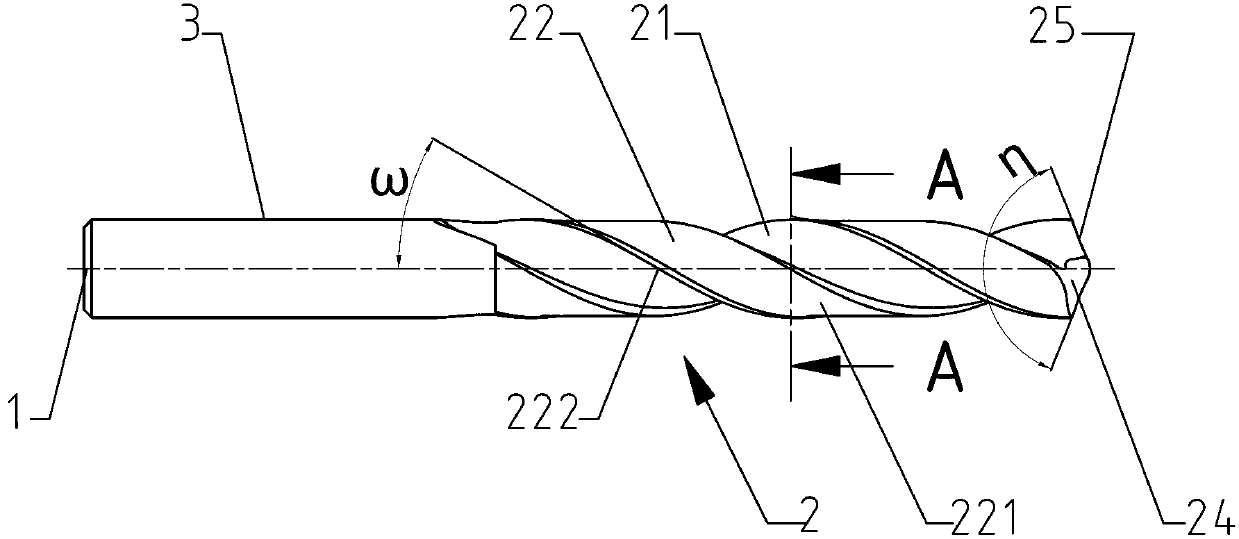

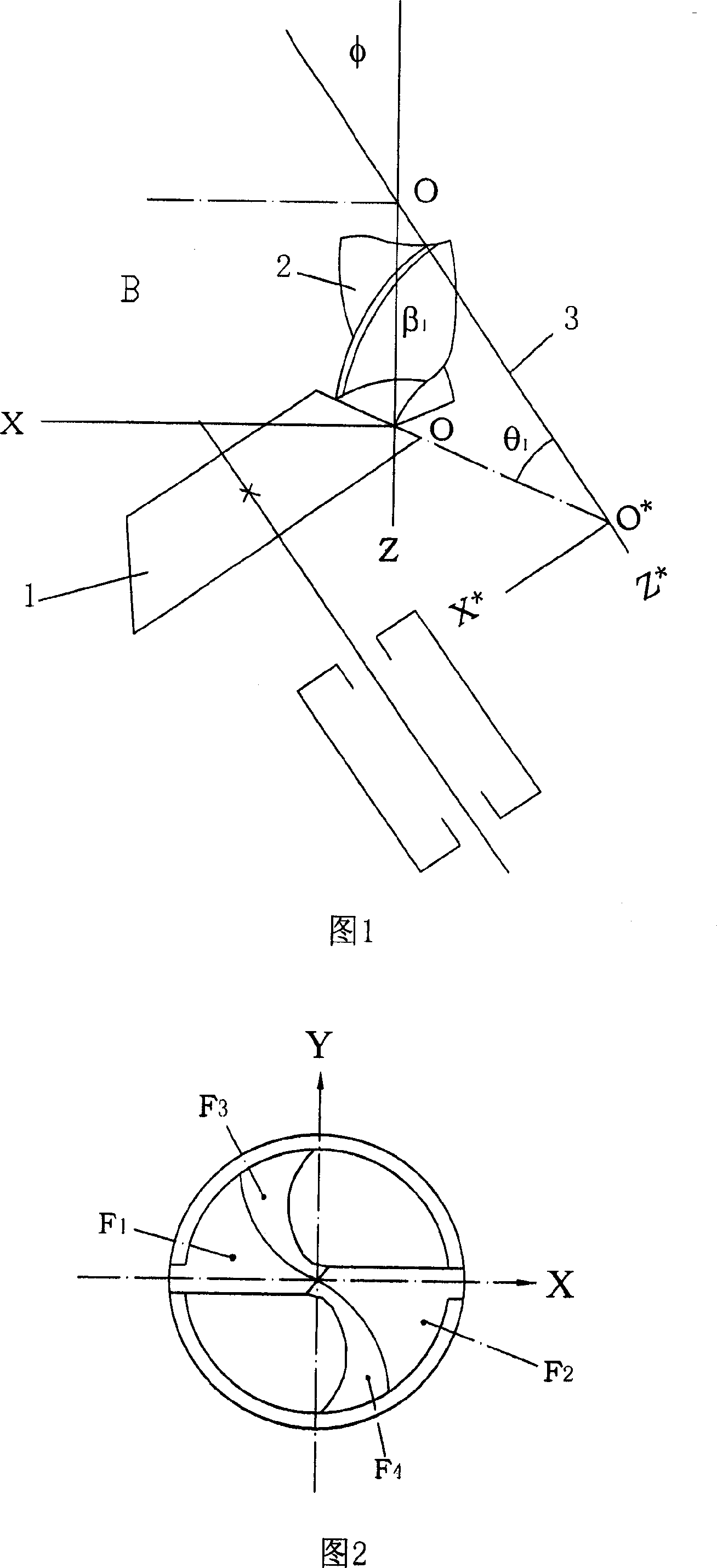

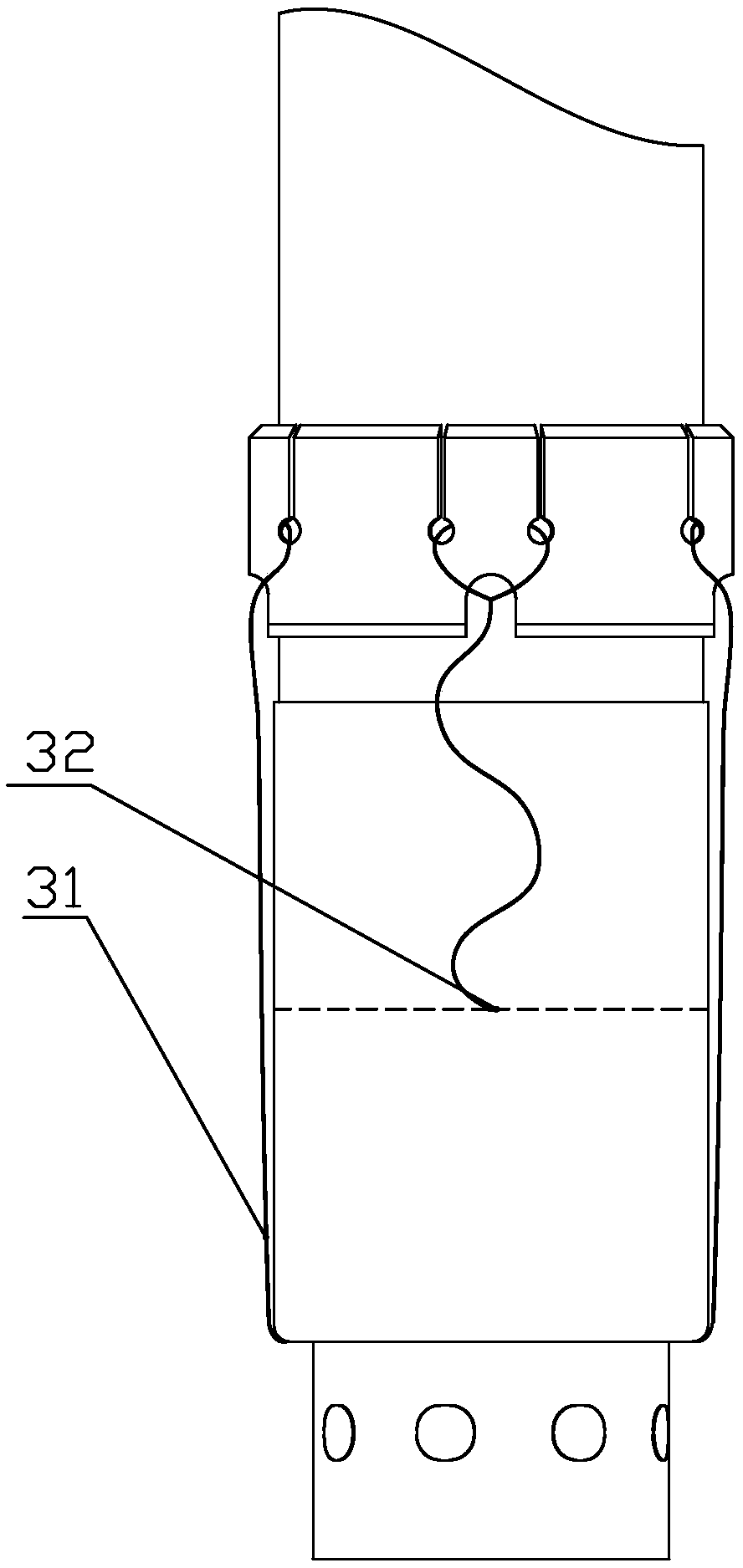

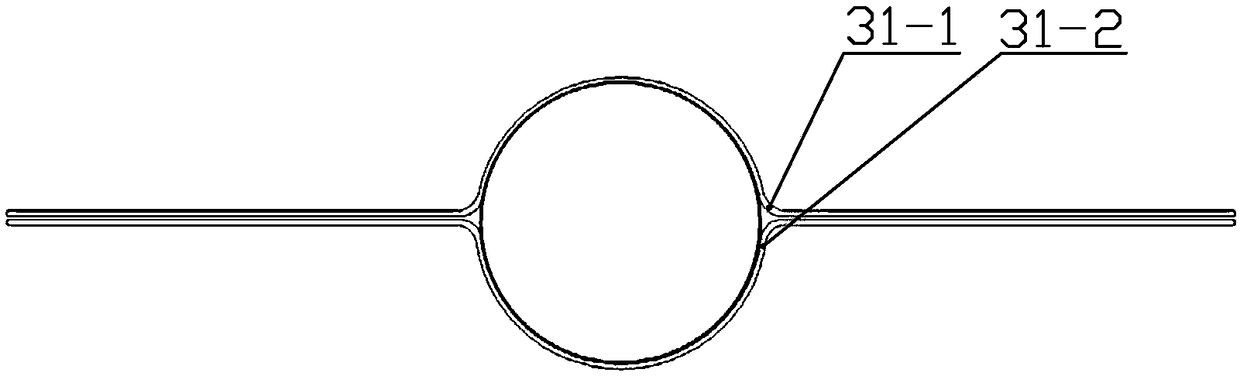

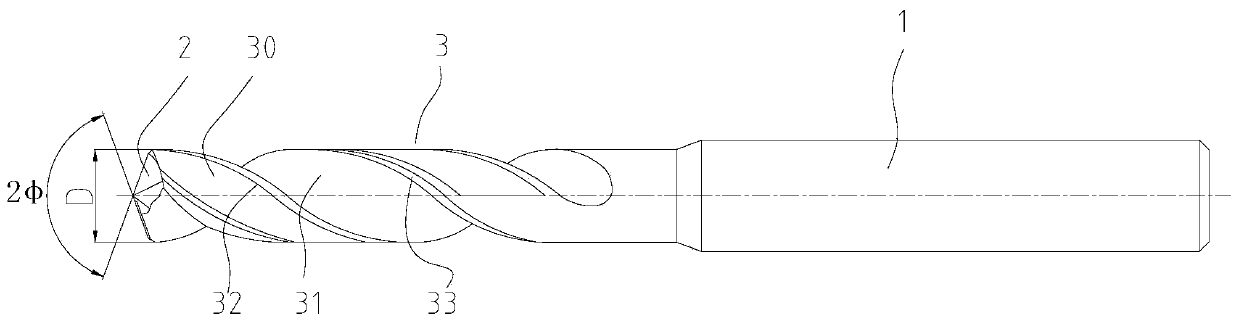

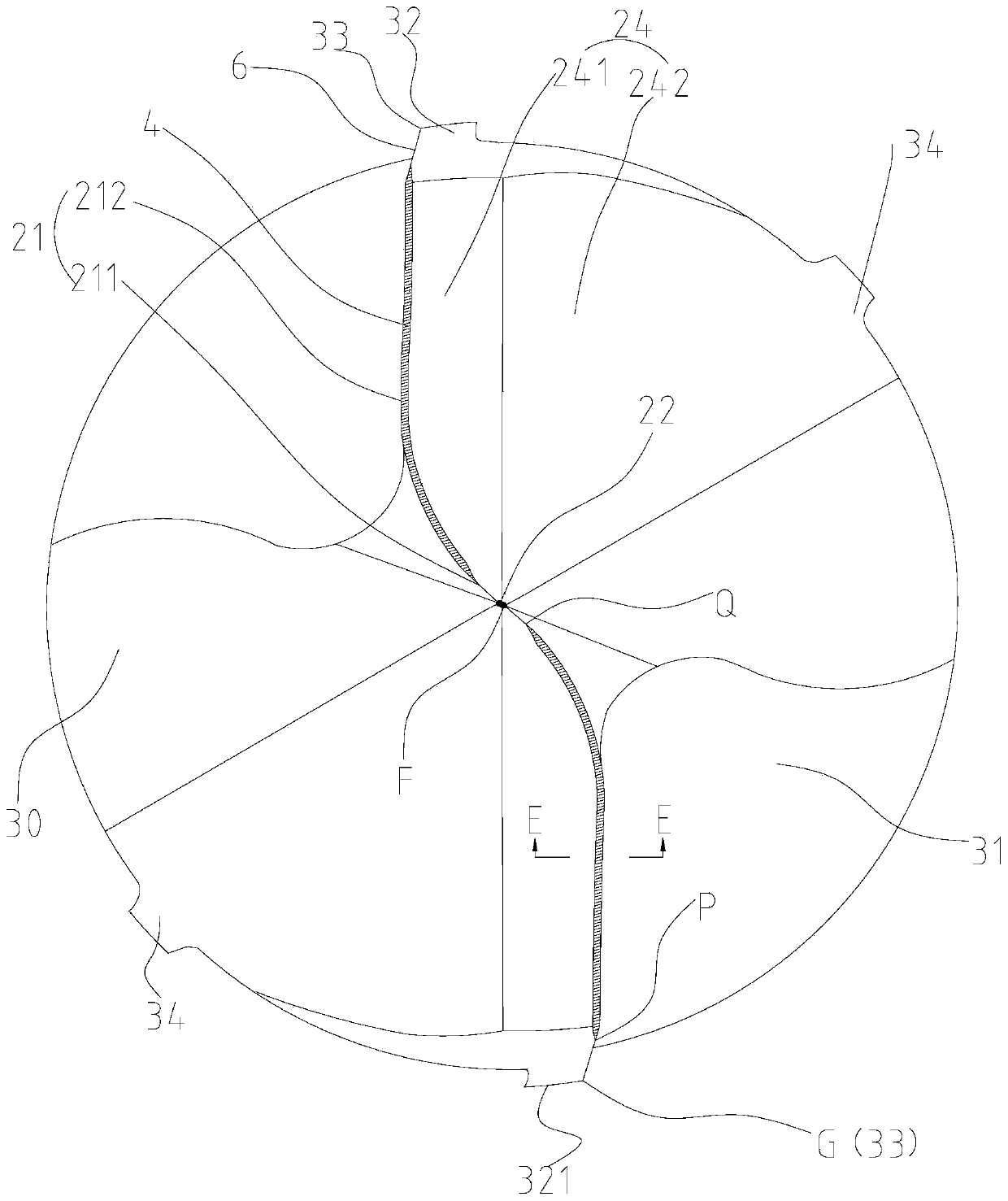

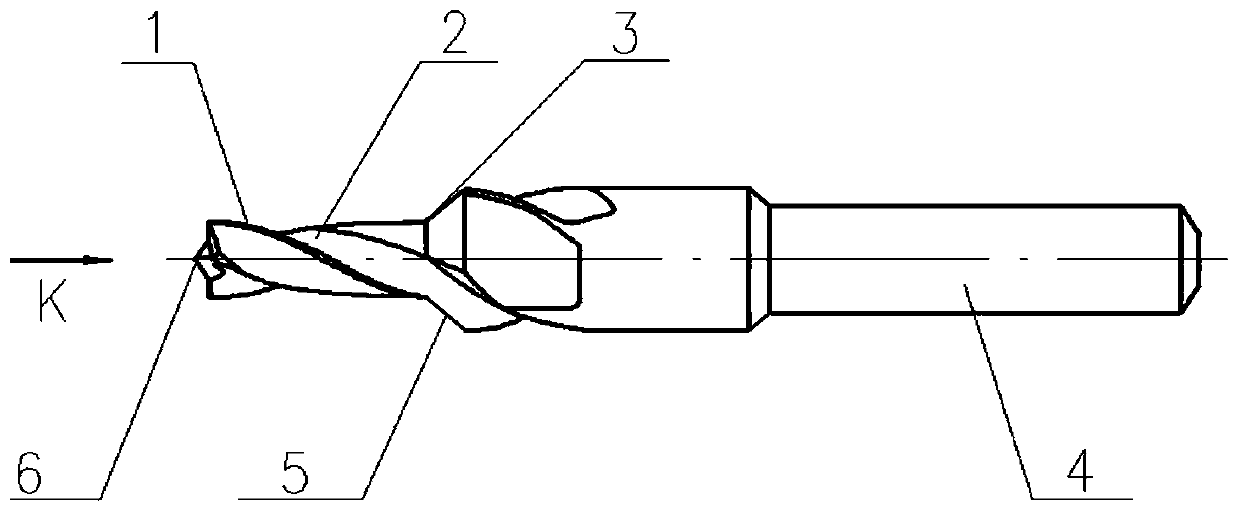

Twist drill with spiral cutting back tool

ActiveCN103128346AExcellent machinabilityGood centering effectTwist drillsStress concentrationEngineering

The invention discloses a twist drill with a spiral cutting back tool. The twist drill with the spiral cutting back tool comprises a cutting portion which rotates around an axis and a handle portion which matches with a jacket. Two grooves which extend from the front end of the cutting portion to the handle portion in a spiral mode and are sued for discharging cutting chips are formed in the cutting portion. The cutting portion is further provided with blade backs which are respectively connected with the periphery of the two grooves. The twist drill with the spiral cutting back tool is characterized in that the grooves form two spiral cutting back tool faces at the front end of the cutting portion, the two cutting back tool faces are intersected in a drill core position to form an S-shaped drill core cutting blade and two main cutting blades, the main cutting blade is connected with the S-shaped drill core cutting blade through a cutting blade connection portion in a smooth mode, each cutting back tool face begins from the main cutting blade and is formed by smoothly connecting a main back blade face, a transition face and a the cutting back tool face stop face. According to the twist drill with the spiral cutting back tool, the spiral cutting back tool faces are intersected to form the S-shaped drill core cutting blade which is connected with the main cutting blade in a smooth mode, stress concentration is greatly reduced, drilling load and centring capacity are further improved, and the twist drill with the spiral cutting back tool is easy to be widely popularized.

Owner:大连远东工具有限公司

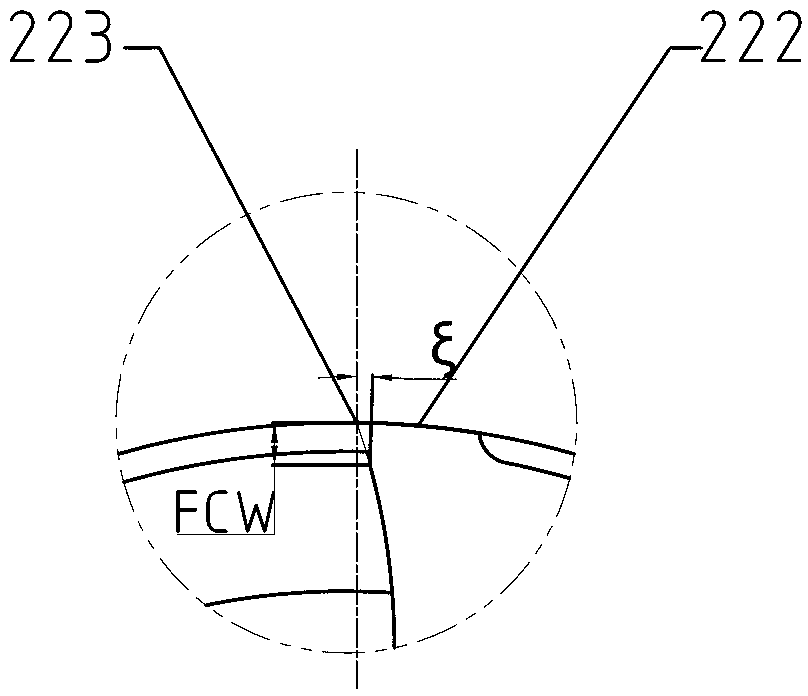

Full helicoidal surface Micro-drill web thinning method

InactiveCN101081483AGood centering effectImprove drilling performanceTwist drillsEngineeringThinning

The process of grinding the chisel edge of small spiral bit includes the following steps: regulating the relative locations of grinding wheel and bit based on the chisel edge grinding coefficient to make the tail gap of the back face in the bit aligned to the grinding wheel, fixing one of the bit and the grinding wheel and making the other move linearly along the axis of the spiral back face until the grinding wheel grinds to the center of the bit to form the second back plane in the tail gap; and turning the bit around its axis by 180 deg to grind one other symmetrical back plane. The process can decrease the sharp chisel edge angle in the bit center, raise the centering capacity of the bit, improve the drilling capacity and drilling performance of the bit.

Owner:HUNAN UNIV

Adjustable shaft part drilling jig

InactiveCN105618820AGuaranteed verticalityGuaranteed central locationDrill jigsMechanical engineering

Owner:GUIZHOU HANGRUI SCI & TECH

Hydraulic casing centralizer with double hydraulic cylinders

ActiveCN104278955AGood centering effectImprove the righting effectDrilling rodsDrilling casingsWell cementingGeotechnical engineering

The invention relates to the technical field of casing centralizing devices and discloses a hydraulic casing centralizer with double hydraulic cylinders. The hydraulic casing centralizer comprises a casing nipple, an upper hydraulic cylinder barrel, a lower hydraulic cylinder barrel, an upper backstop shaft sleeve, a lower backstop shaft sleeve, a first limiting device, a second limiting device, a third limiting device, a fourth limiting device and at least one spring plate, wherein the first limiting device is fixedly arranged at the outer side of the upper part of the casing nipple; the outer side of the upper part of the casing nipple is sleeved by the upper backstop shaft sleeve; and the outer side of the upper part of the upper backstop shaft sleeve is fixed together with the inner side of the lower part of the first limiting device. The hydraulic casing centralizer is reasonable and compact in structure, and convenient to use; both the upper hydraulic cylinder barrel and the lower hydraulic cylinder barrel can push the spring plate to expand, so that the centering effect of a casing connected with the hydraulic casing centralizer in a well can be improved, and the centralizing effect of the hydraulic casing centralizer to the casing is improved; and meanwhile, the formed cement sheath is uniform in thickness, the well cementation quality is improved, and risks existing in later-period production and oil and gas invasion in operation are reduced.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

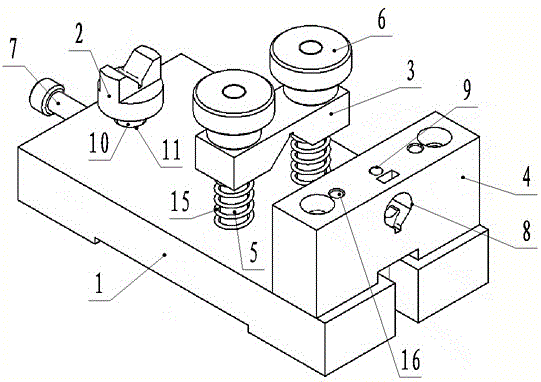

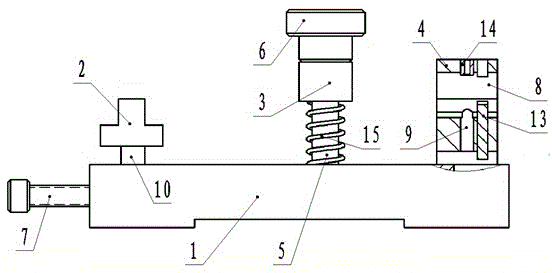

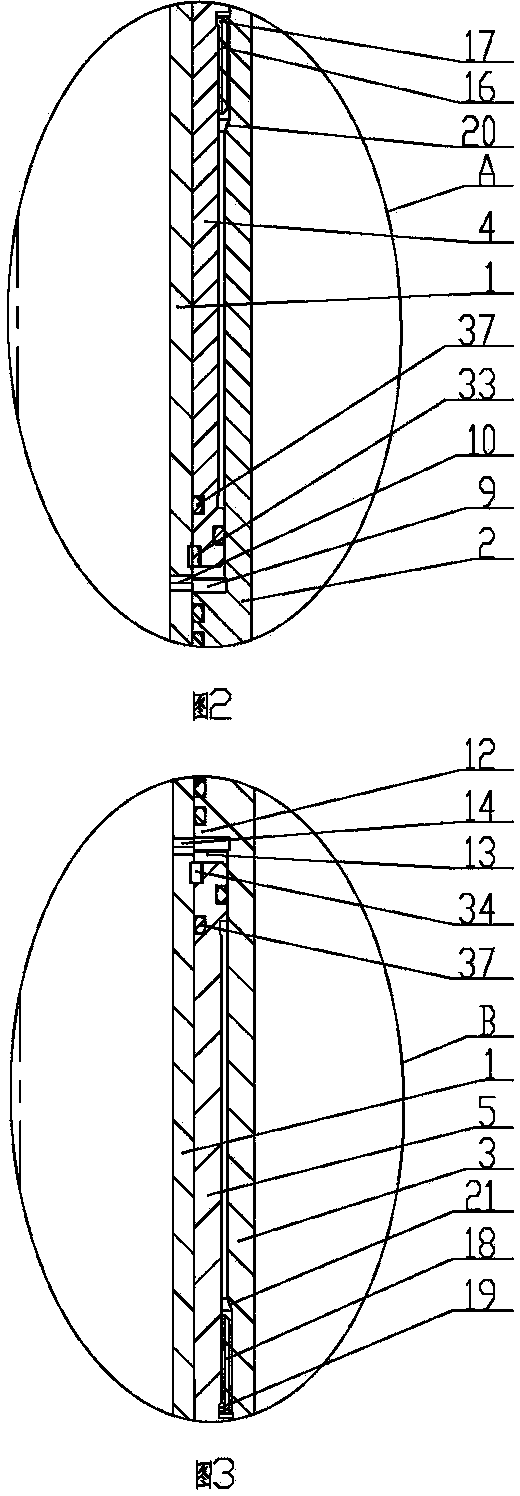

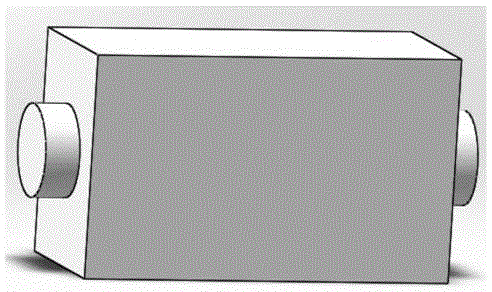

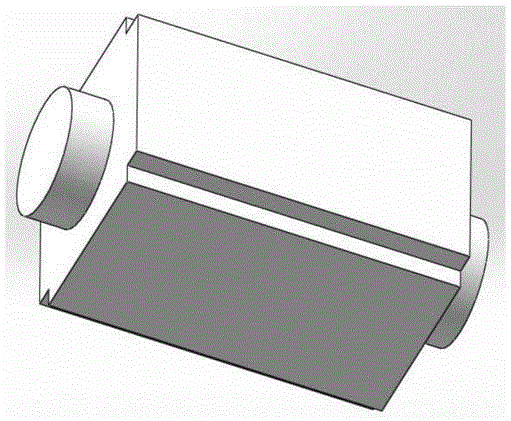

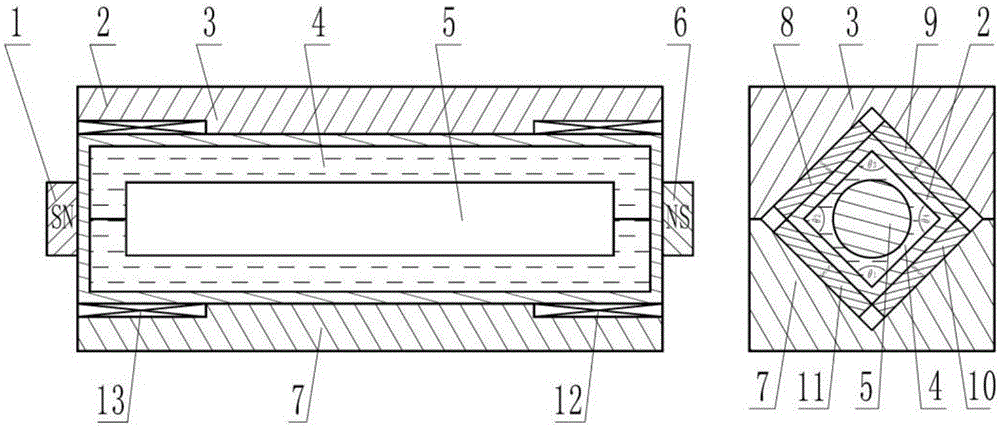

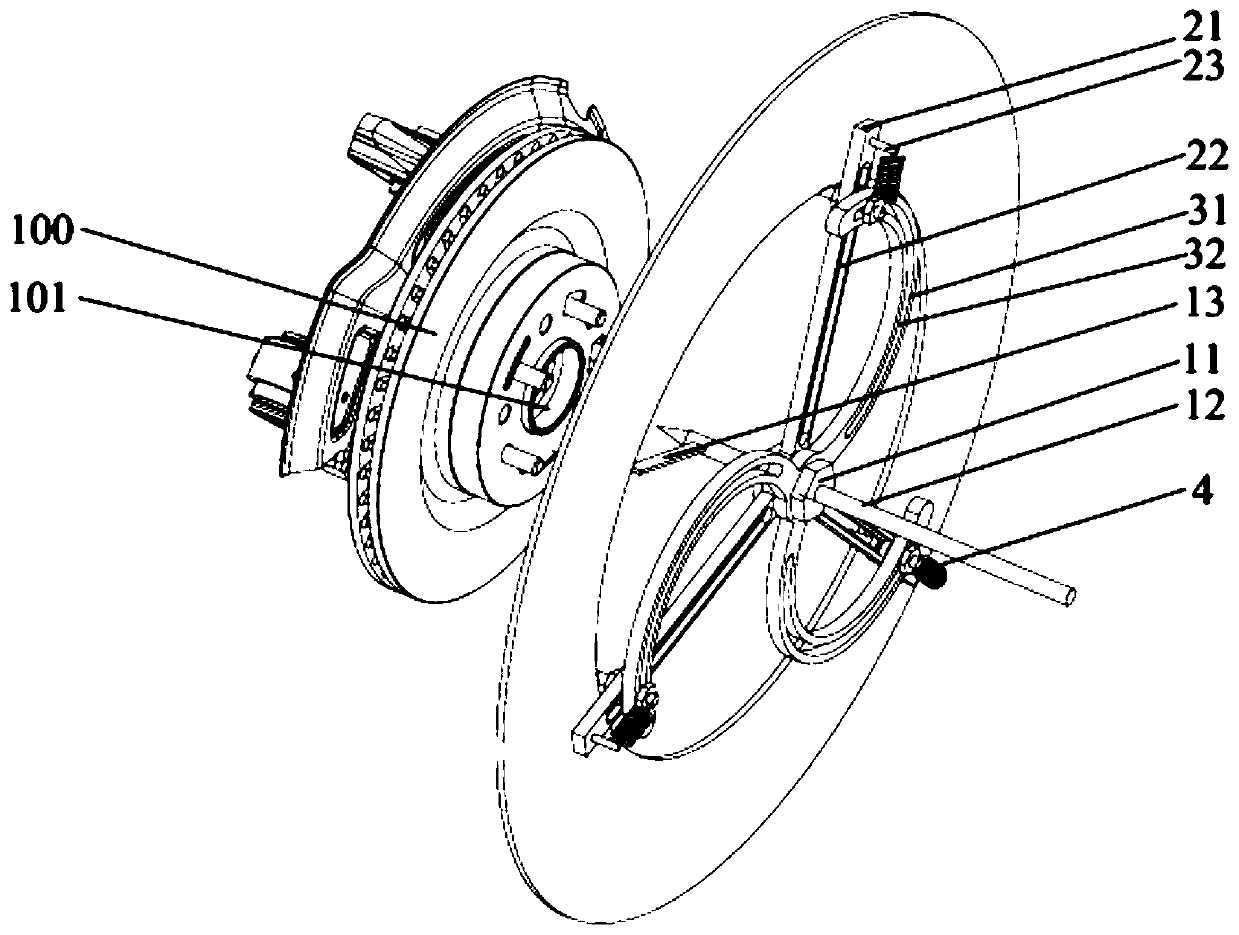

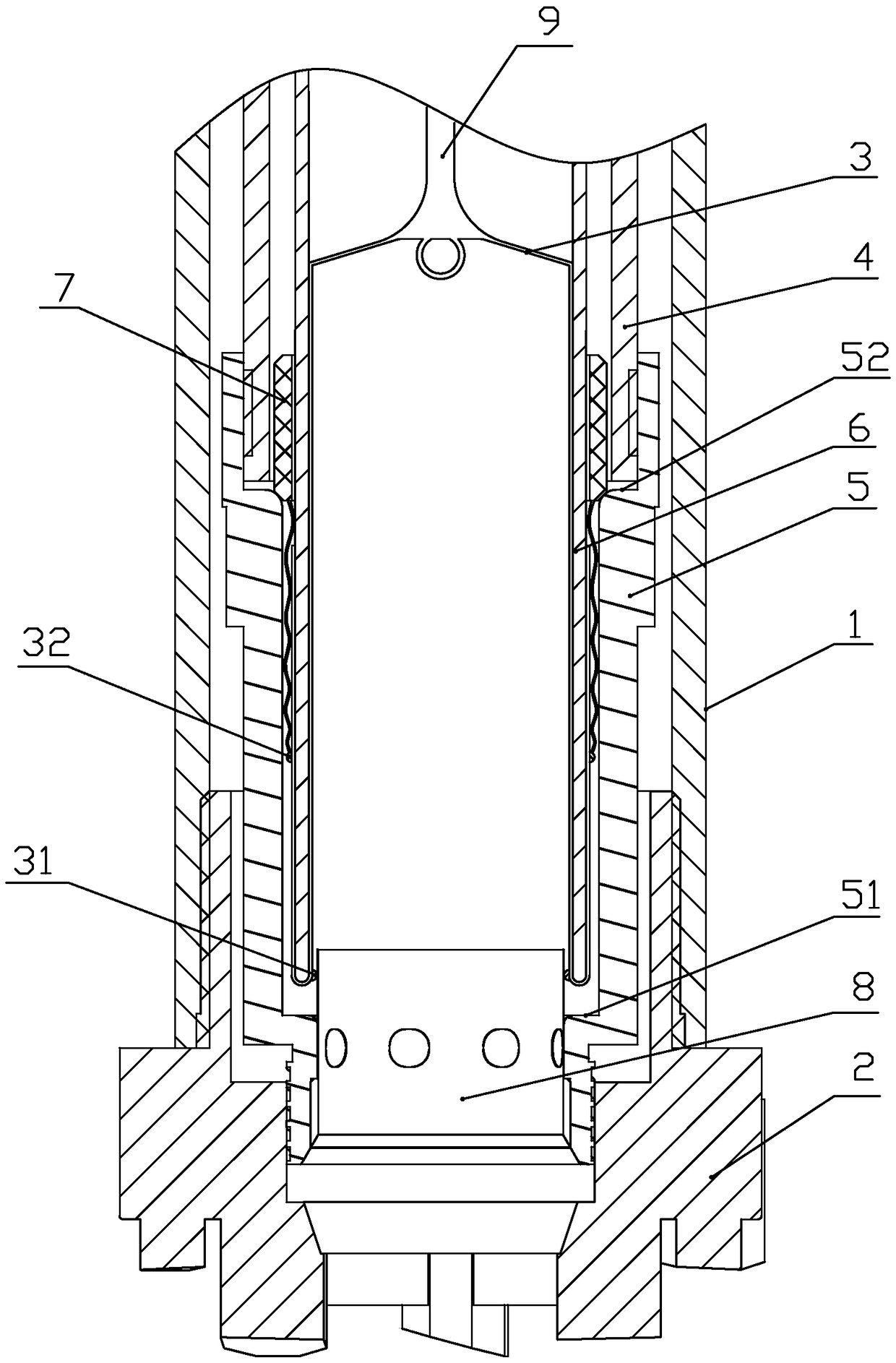

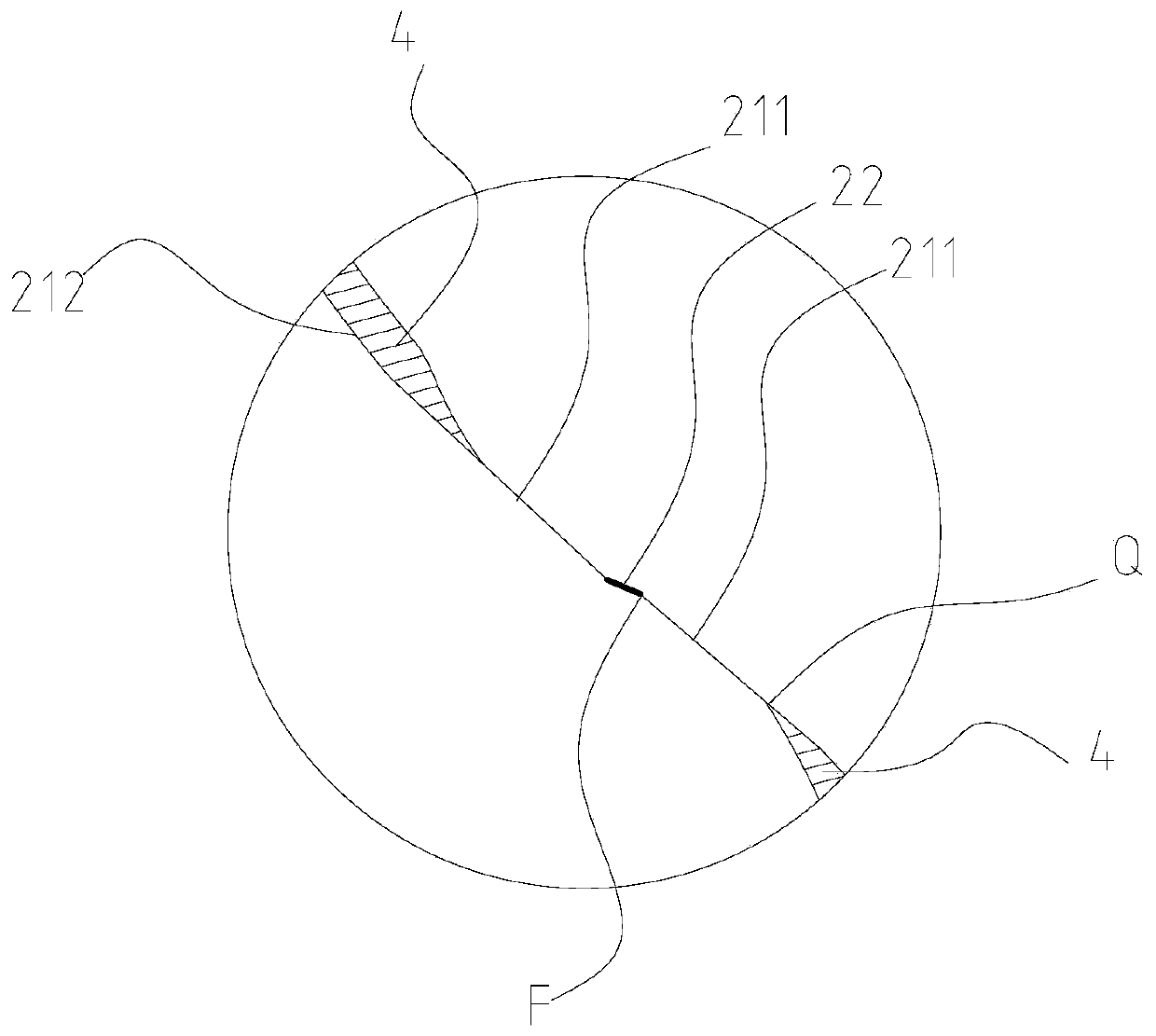

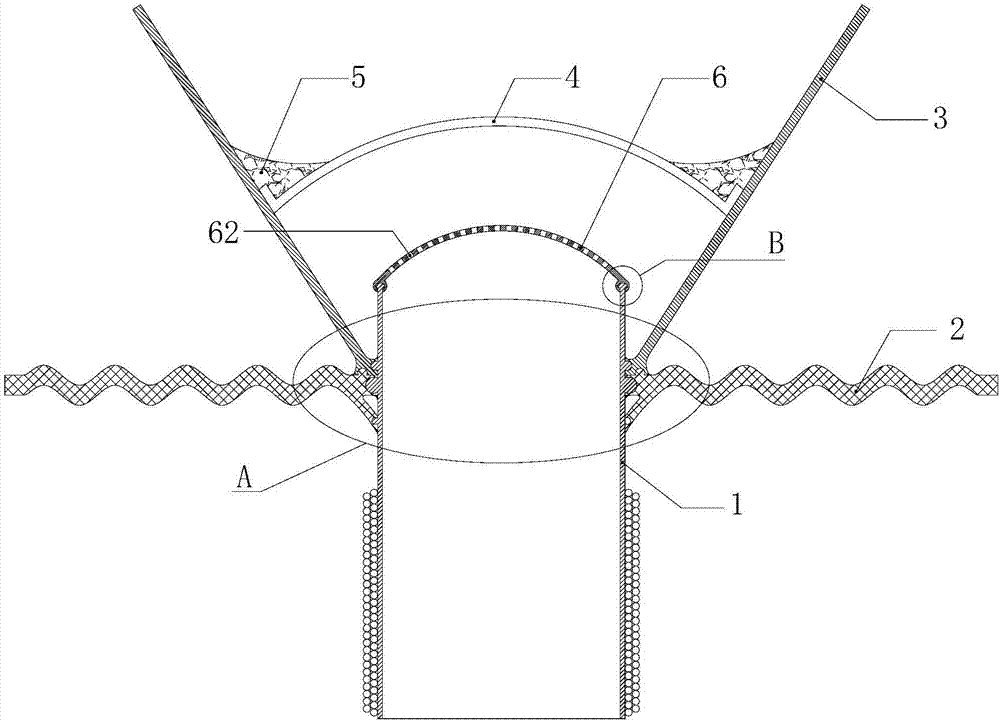

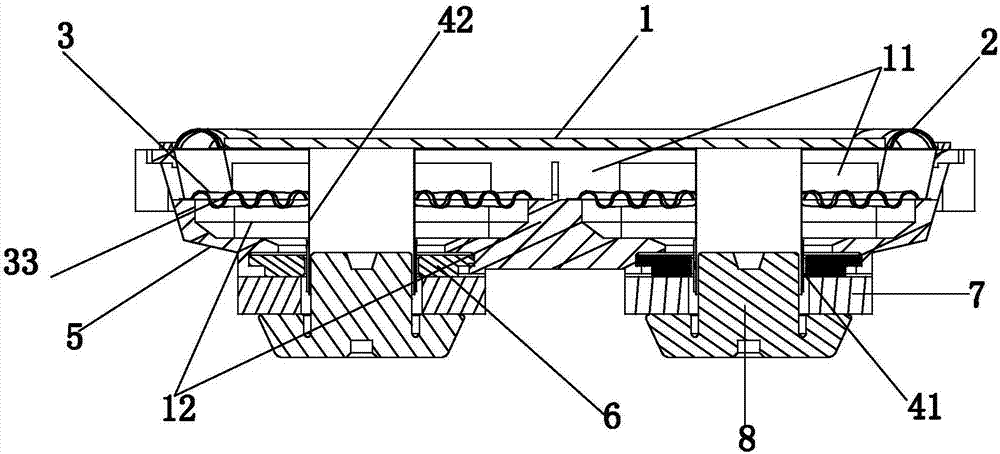

Cylindrical first-order buoyancy magnetic liquid vibration absorber

InactiveCN104912994ASuspension stabilityGood centering effectSpringsNon-rotating vibration suppressionMagnetic liquidsMagnet

The invention relates to a cylindrical first-order buoyancy magnetic liquid vibration absorber, and belongs to the field of mechanical engineering vibration. The cylindrical first-order buoyancy magnetic liquid vibration absorber successfully solves the problem that an existing magnetic liquid clamping vibration absorber cannot be applied in engineering practice caused by multiple structures. The cylindrical first-order buoyancy magnetic liquid vibration absorber comprises a first limiting permanent magnet (1), a shell (2), an upper V-shaped armature (3), the magnetic liquid (4), a mass block (5), a second limiting permanent magnet (6), a lower V-shaped armature (7), a first suspension permanent magnet (8), a second suspension permanent magnet (9), a third suspension permanent magnet (10) and a fourth suspension permanent magnet (11). When the outer side words vibrated, the mass block (5) moves in a cavity, and the magnetic liquid (4) flows in a gap between the inner hole wall of the shell (2) and the mass block (5), so that energy is absorbed, and the purpose for reducing vibration is achieved.

Owner:BEIJING JIAOTONG UNIV

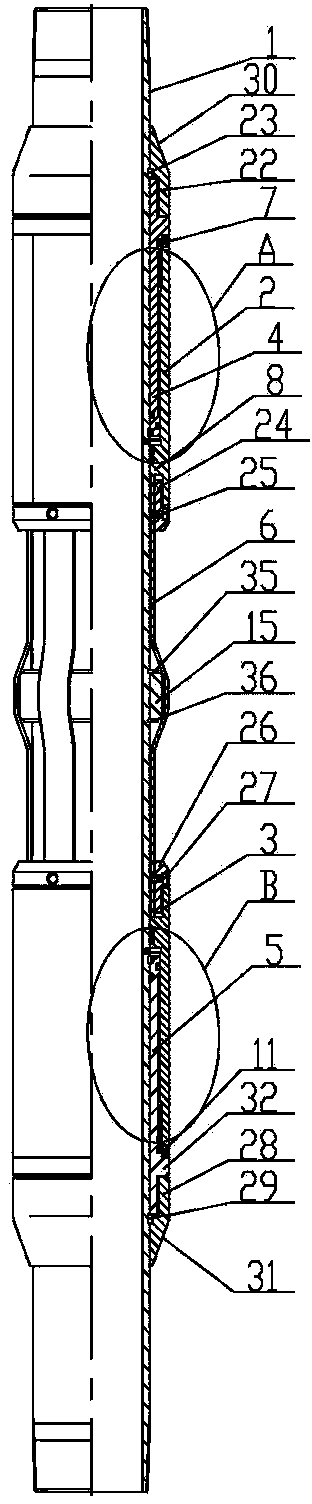

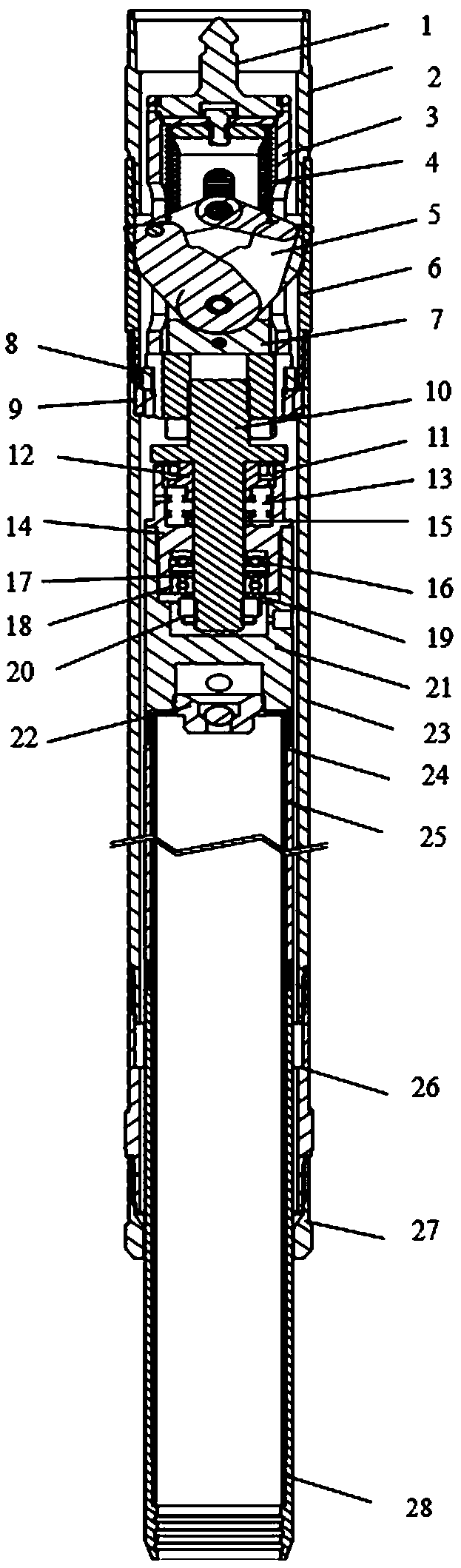

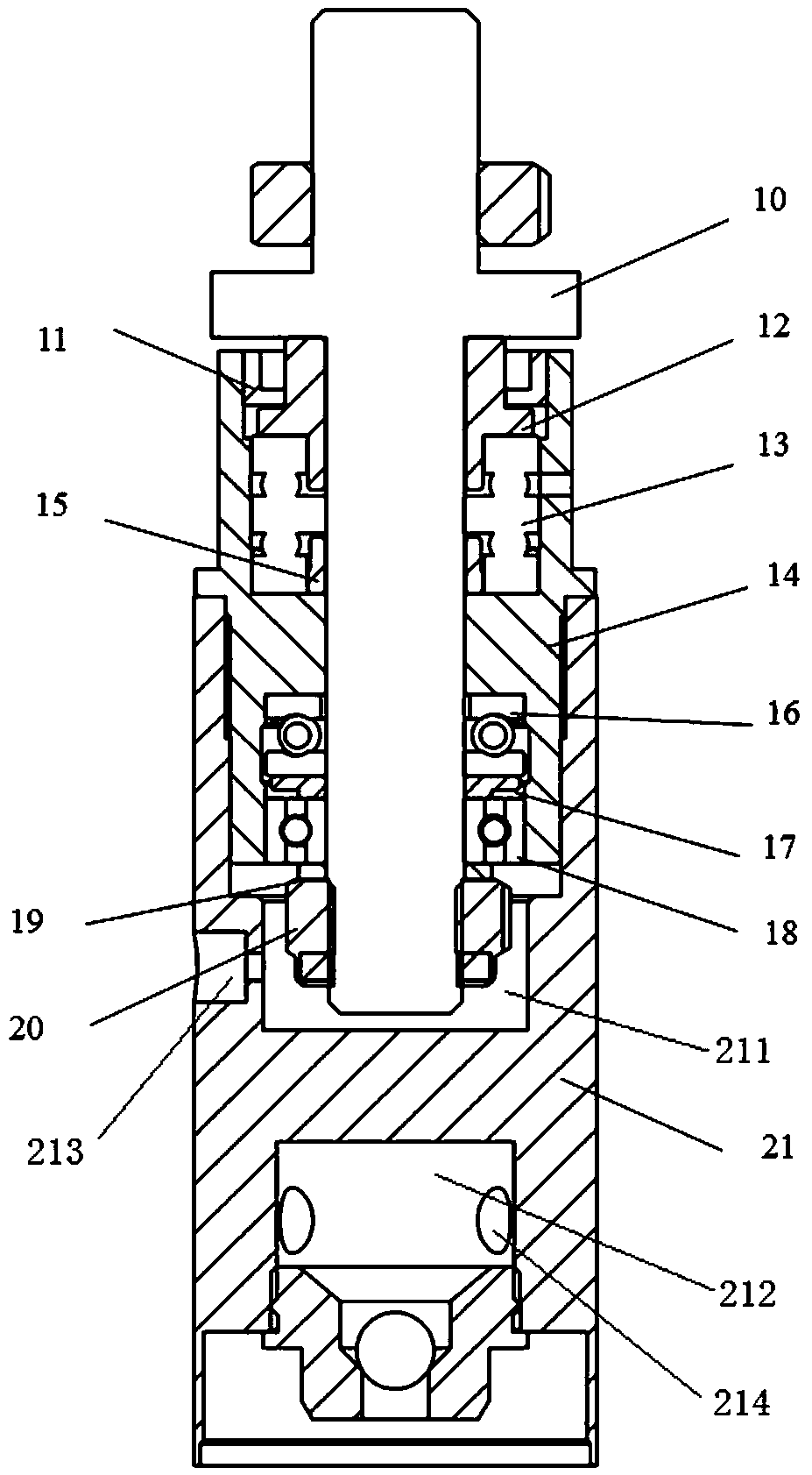

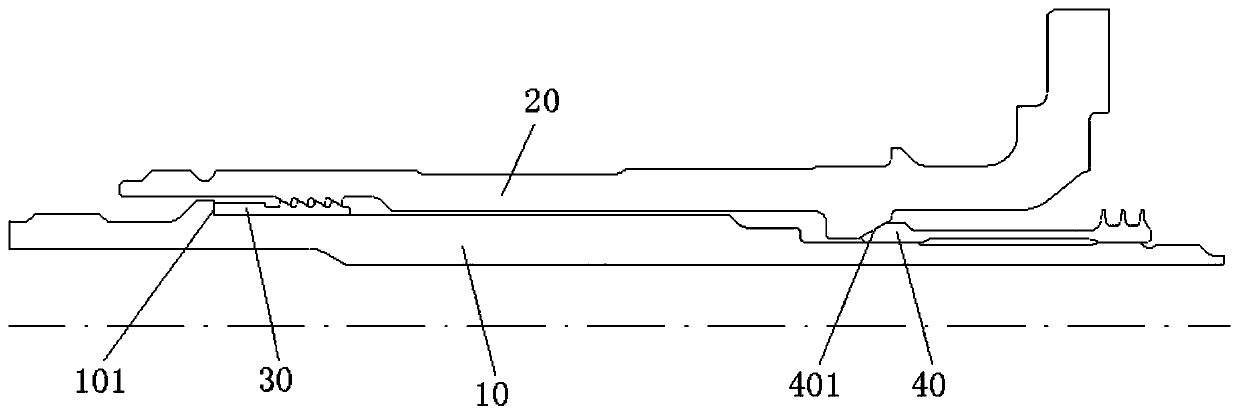

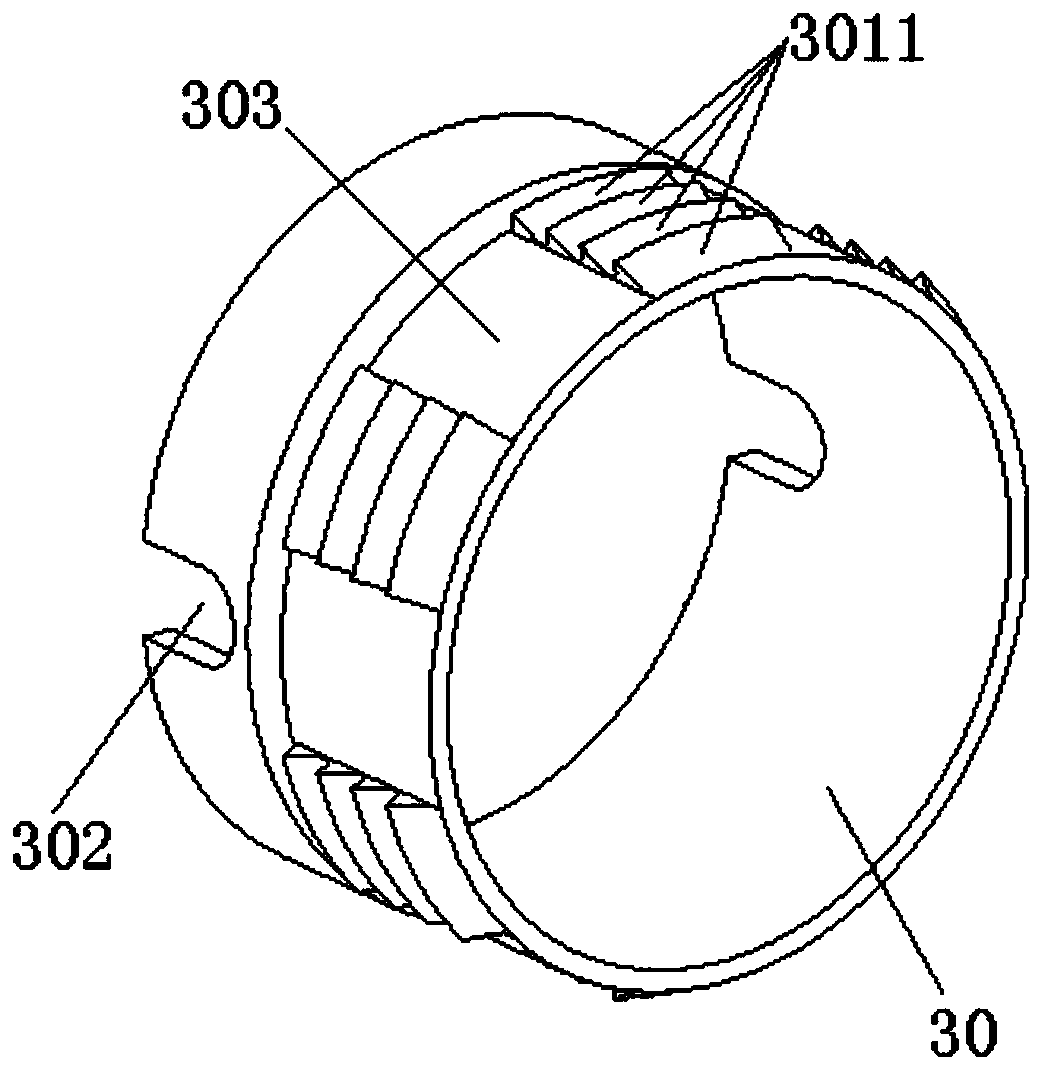

Engineering exploration wire line coring drilling tool suitable for seafloor drilling machines

The invention discloses an engineering exploration wire line coring drilling tool suitable for seafloor drilling machines. The engineering exploration wire line coring drilling tool includes an outertube assembly and an inner tube assembly; the outer tube assembly includes an elastic clamp blocking head, an elastic clamp chamber, an outer tube, a hole expanding machine and a drilling bit which are connected in sequence; the inner assembly includes a salvaging spearhead, an elastic clamp locating mechanism, an elastic clamp support, a single moving mechanism, an inner tube joint, a backwater ball valve, an inner tube and a core screened pipe; the salvaging spearhead is connected with the elastic clamp locating mechanism, and the elastic clamp locating mechanism is connected with the elastic clamp support; a dangling loop is arranged on the side wall of the elastic clamp support and is placed on a stay ring on the inner wall of the outer tube; the elastic clamp support is connected withthe single moving mechanism, and the single moving mechanism is connected with the inner tube joint; the lower end of the inner tube joint is connected with the upper end of the inner tube, and the core screened pipe is arranged in the inner tube; and the single moving mechanism includes a mandrel, a casing pipe end cover, an upper force transmission clamp sleeve and a lower force transmission clamp sleeve. According to the engineering exploration wire line coring drilling tool suitable for the seafloor drilling machines, the single moving performance is stable, the centering effect of a bearing is good, the disturbance degree for a soil sample is low, and the condition of sticking is prevented when the inner tube assembly is salved.

Owner:HUNAN UNIV OF SCI & TECH

Cylindrical first-order buoyancy magnetic liquid acceleration sensor

InactiveCN105158510ASuspension stabilityGood centering effectAcceleration measurementMagnetic liquidsInductance

A cylindrical first-order buoyancy magnetic liquid acceleration sensor belongs to the field of mechanical engineering vibration, and successfully solves the problem that conventional magnetic liquid acceleration sensors cannot be applied in engineering practice due to a plurality of structure problems. The cylindrical first-order buoyancy magnetic liquid acceleration sensor comprises a first limiting permanent magnet (1), a housing (2), an upper V-shaped armature (3), magnetic liquid (4), a mass block (5), a second limiting permanent magnet (6), a lower V-shaped armature (7), a first suspension permanent magnet (8), a second suspension permanent magnet (9), a third suspension permanent magnet (10), a fourth suspension permanent magnet (11), a second induction coil (12), and a first induction coil (13); when there is an acceleration signal in the outside world, the mass block (5) moves in a cavity, volume distribution of the magnetic liquid (4) in the housing (2) changes, so that the second induction coil (12) and the first induction coil (13) detect and output inductance signals.

Owner:BEIJING JIAOTONG UNIV

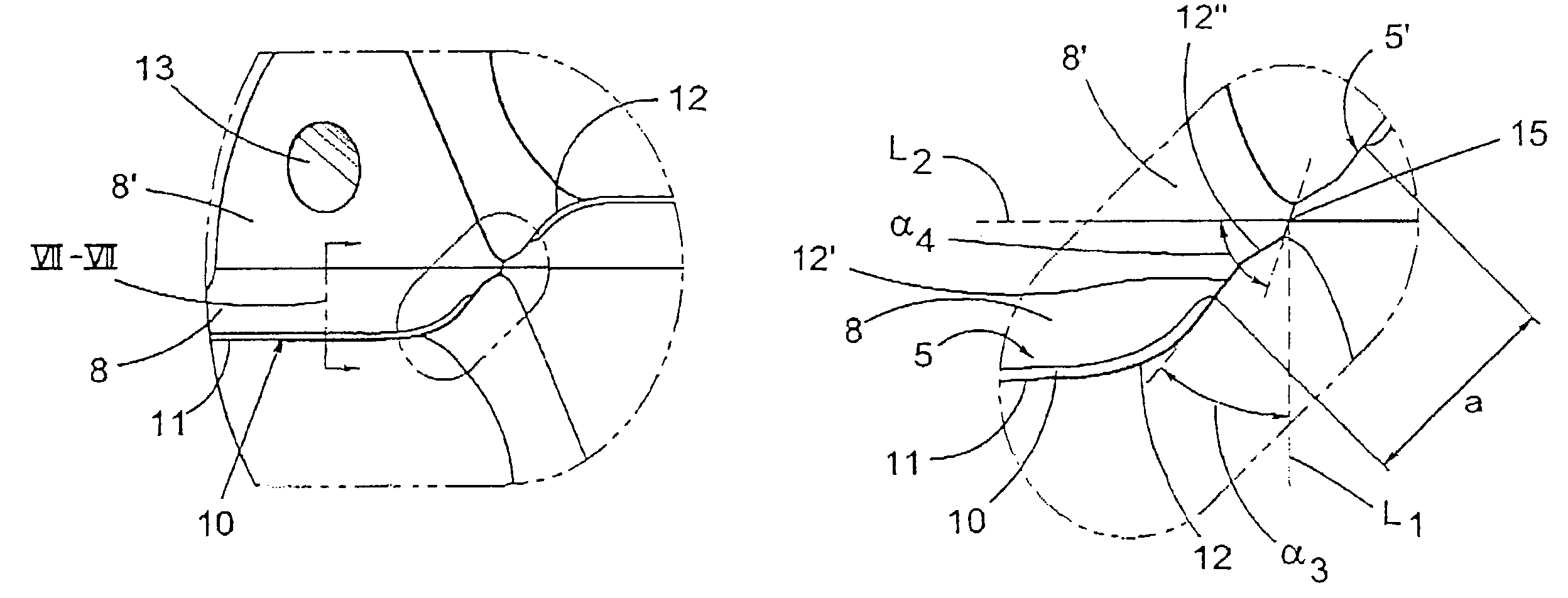

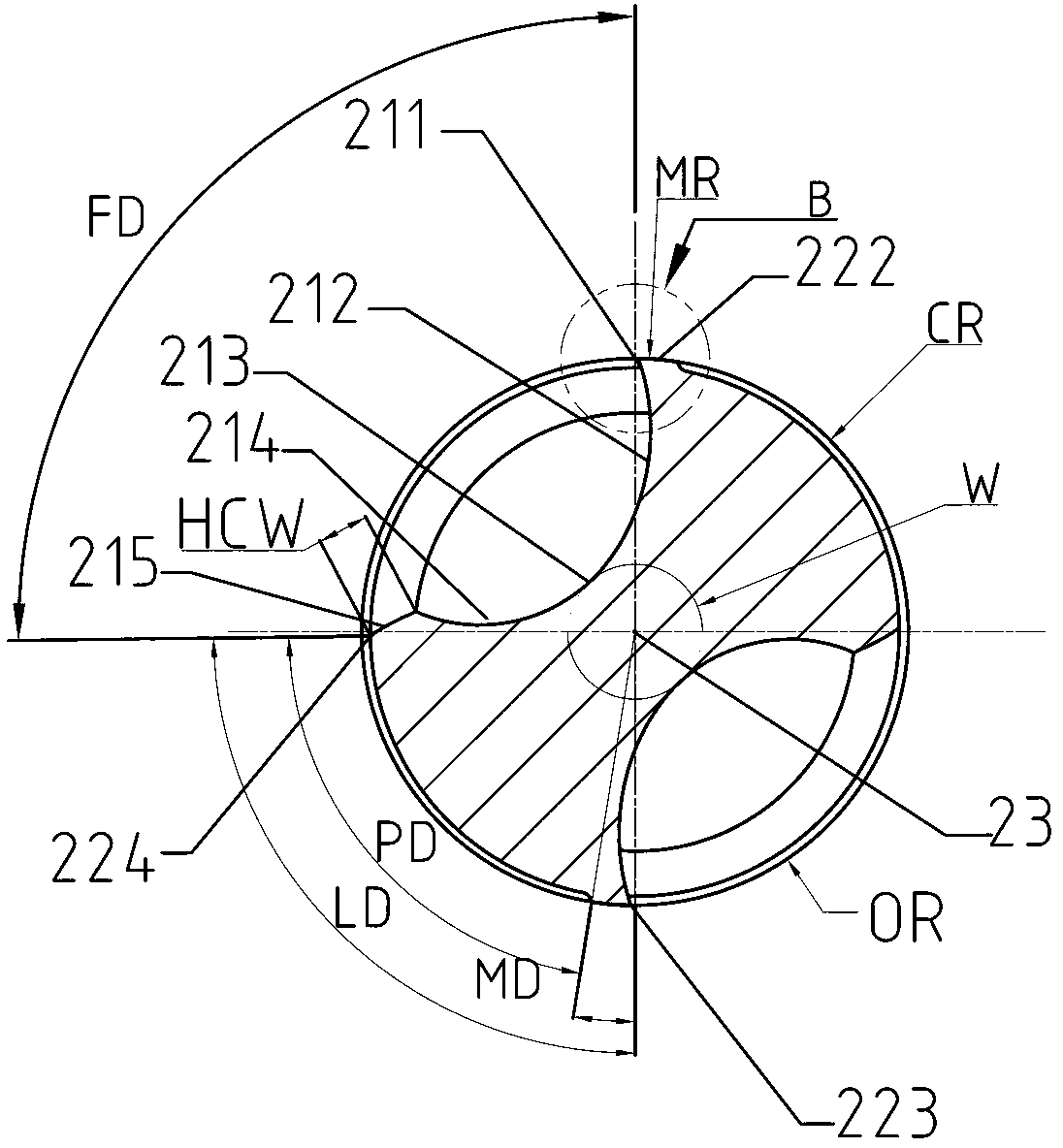

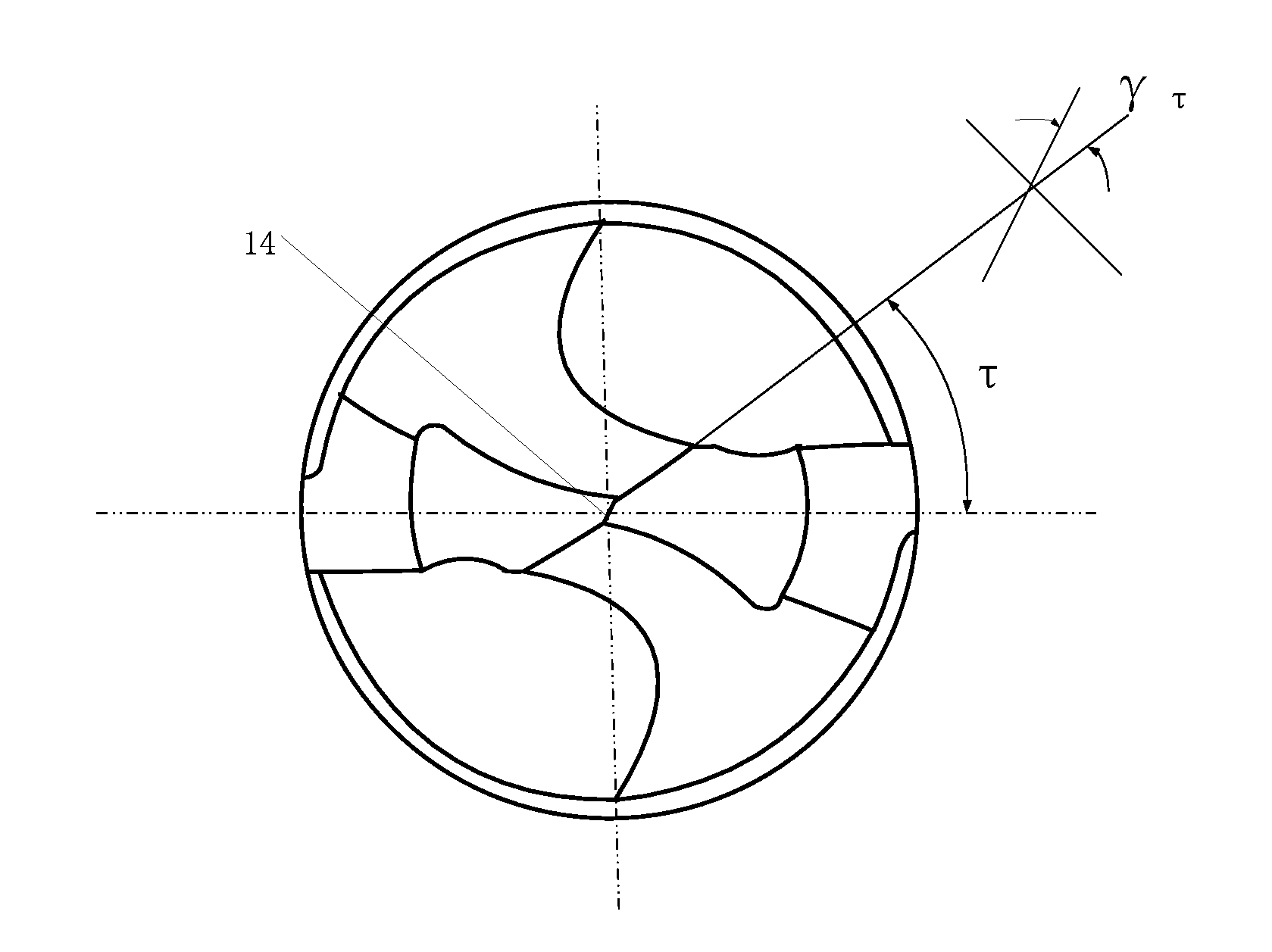

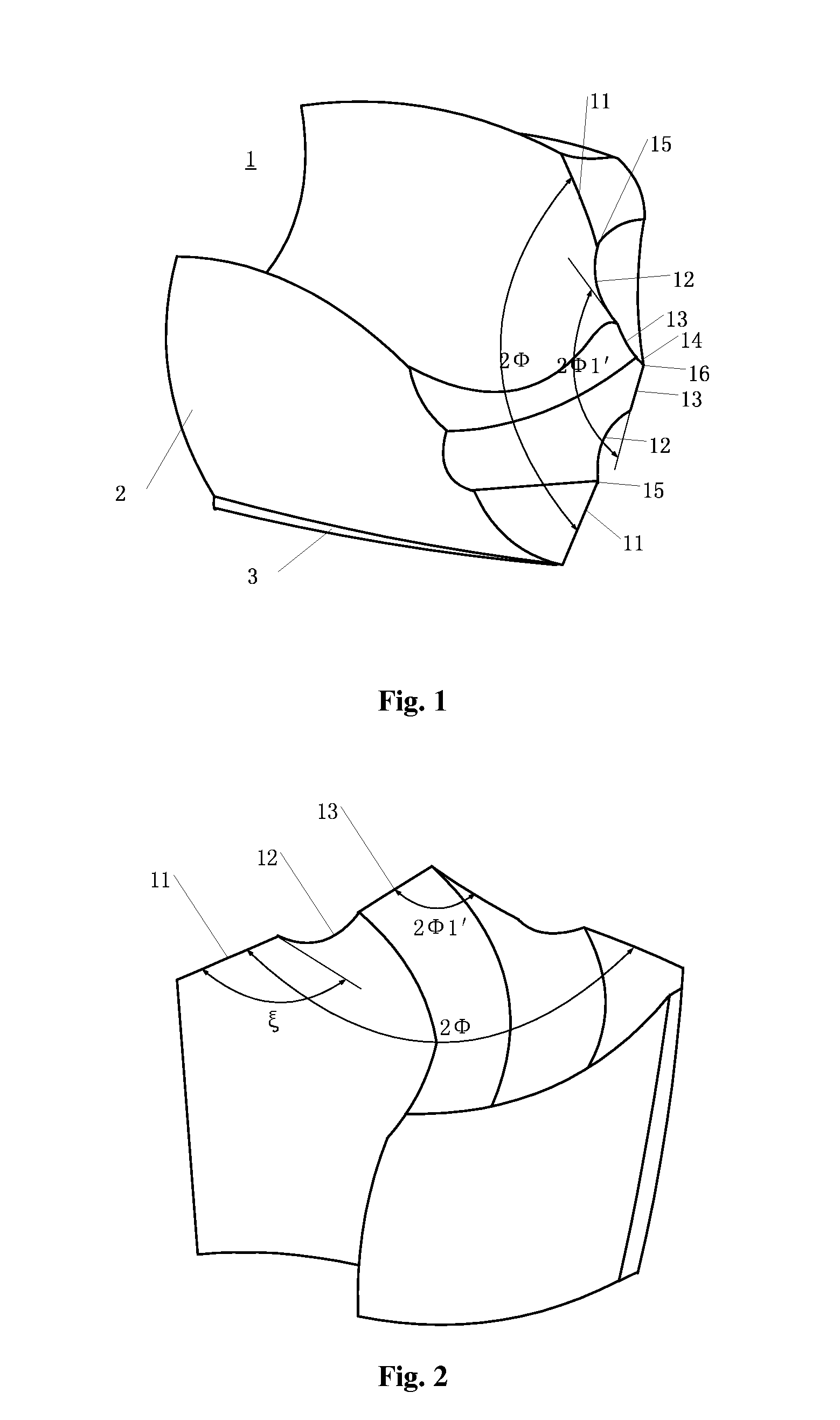

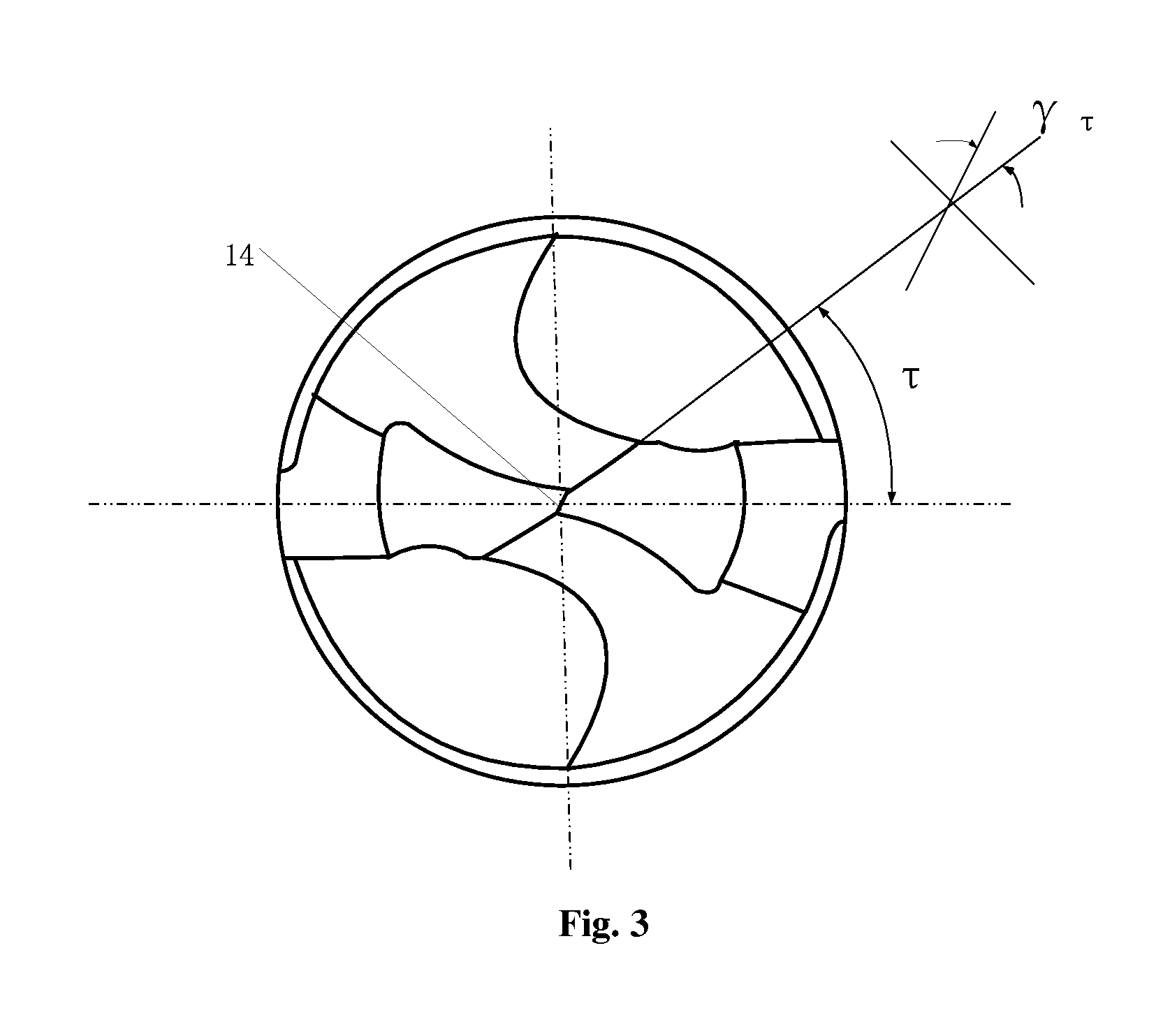

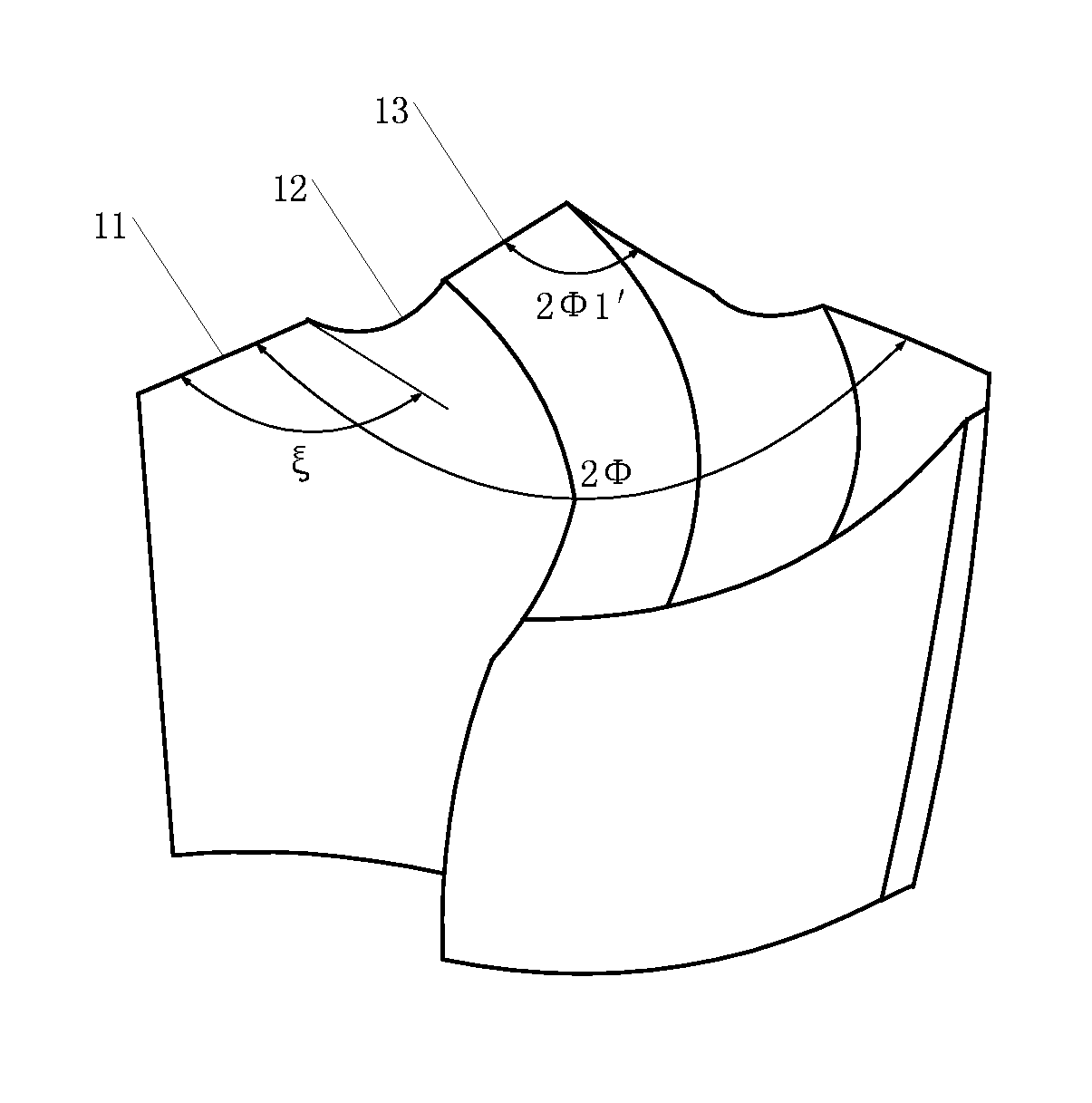

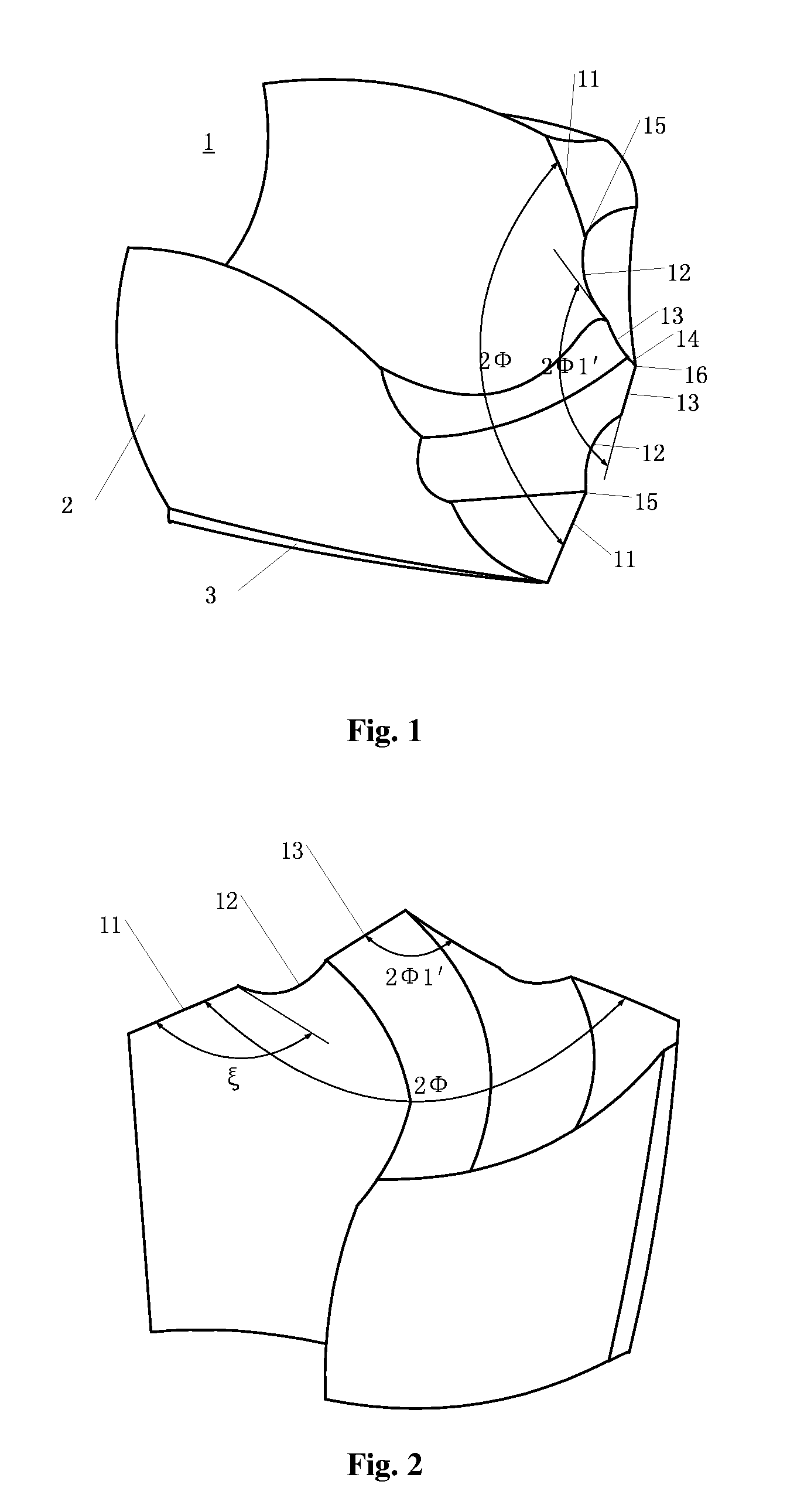

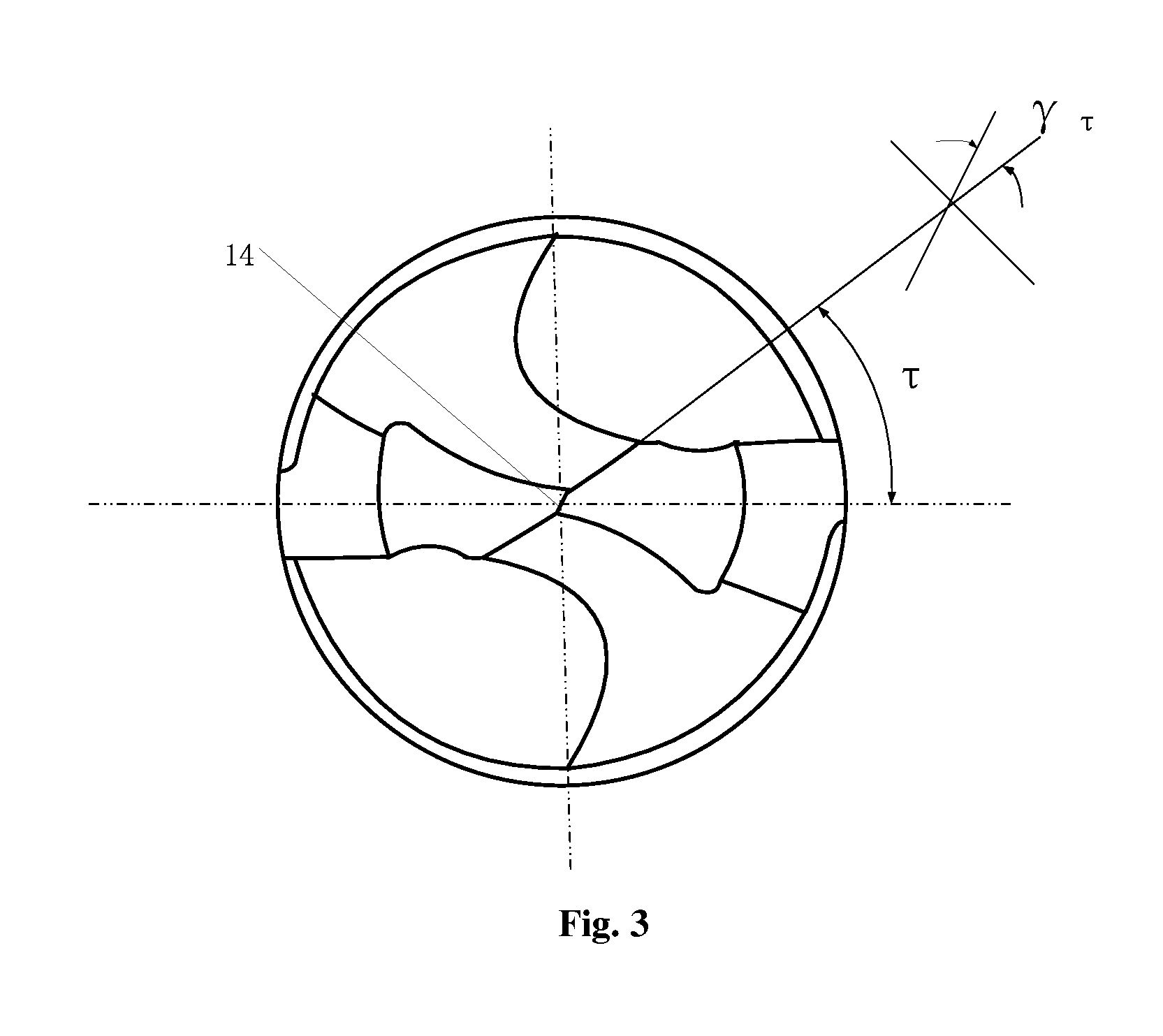

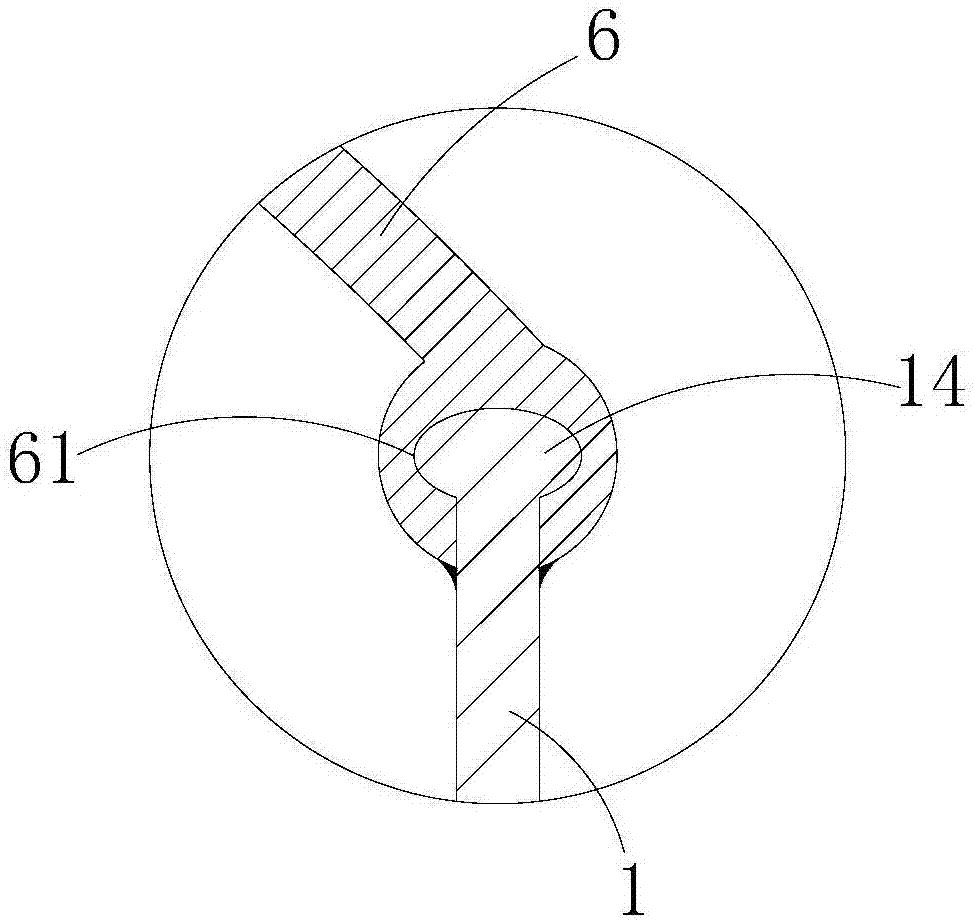

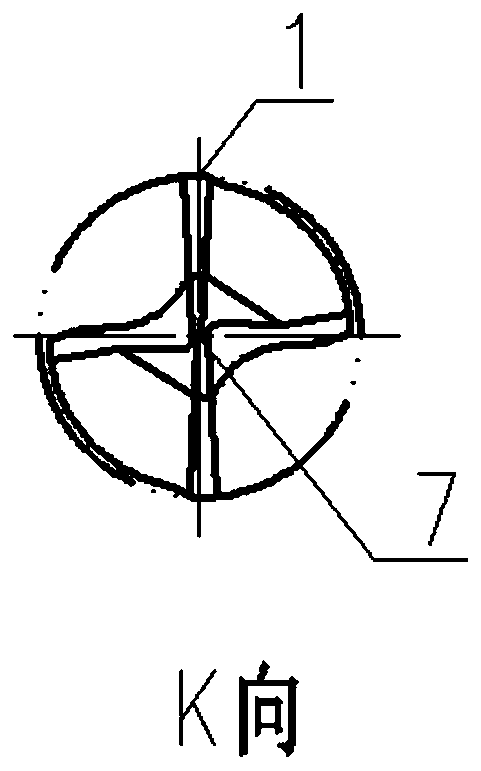

General-purpose multiple-cutting edge drill

InactiveUS20130017029A1Improve roundnessImprove abilitiesWood turning toolsTransportation and packagingGeneral purposeChisel

A general-purpose multiple-cutting edge drill includes: a drill point (1); a drill body (2); margins (3) located on an outer wall of the drill body (2); two lips, wherein, if viewed from an axial direction, from out to inside, each of the two lips successively includes an outer cutting edge (11), an arc cutting edge (12) and an inner cutting edge (13); a chisel edge (14); outer peaks (15) formed by intersection of the outer cutting edges (11) and the arc cutting edges (12); a center peak (16) formed by intersection of two inner flank surfaces and two split surfaces. Moreover, an included angle between the inner cutting edges (13) ranges from 108° to 128°, an included angle between the outer cutting edge (11) ranges from 130° to 140°, and an included angle between the inner cutting edge (13) and outer cutting edge (11) ranges from 28° to 40°.

Owner:NINGBO HUAREN TOLLS +1

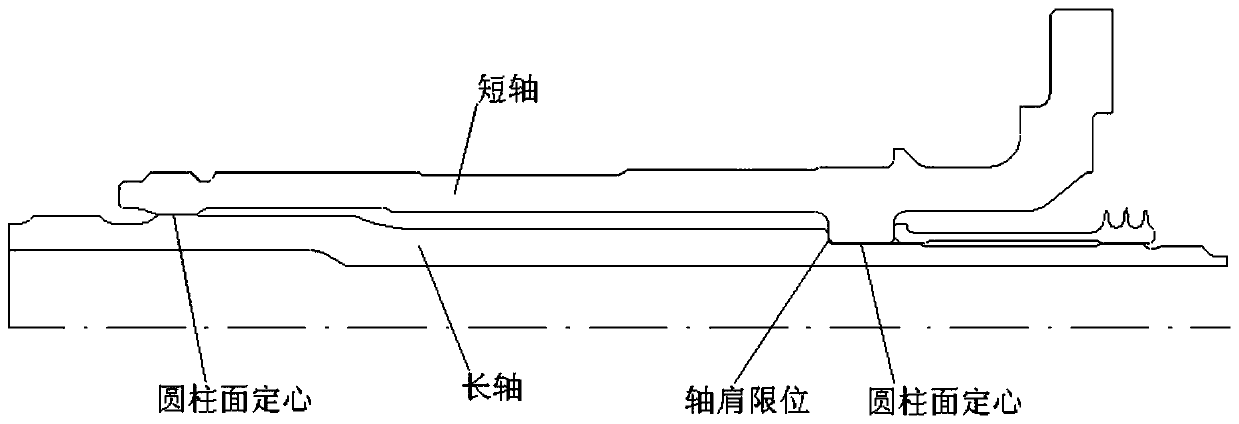

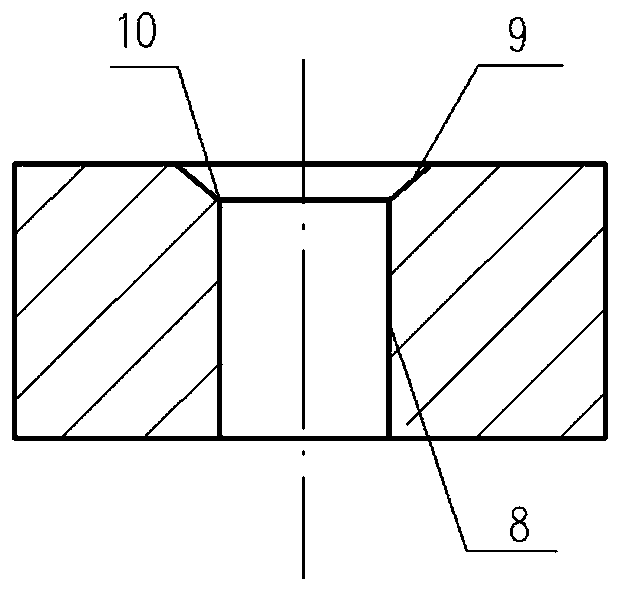

Conical surface centering structure and assembly method

The invention discloses a conical surface centering structure and an assembly method. The conical surface centering structure comprises an inner rotating shaft, wherein an outer rotating shaft is coaxially arranged outside the inner rotating shaft; an annular limiting shaft shoulder is arranged on the outer circle of the first end of the inner rotating shaft; the outer circle of the second end ofthe inner rotating shaft is provided with external threads; a first limiting ring is arranged on the outer circle of the first end of the inner rotating shaft; the first limiting ring is arranged at the inner side of the limiting shaft shoulder, and the end the first limiting ring abuts against the limiting shaft shoulder; the outer ring surface of the first limiting ring fits with the conical surface of the inner peripheral wall of the outer rotating shaft; a second limiting ring is arranged on the outer circle of the second end of the inner rotating shaft; the outer ring surface of the second limiting ring fits with the conical surface of the inner peripheral wall of the outer rotating shaft; the fitting direction of the outer ring surface of the second limiting ring and the conical surface of the inner peripheral wall of the outer rotating shaft is opposite to the fitting direction of the outer ring surface of the first limiting ring and the conical surface of the inner peripheral wall of the outer rotating shaft; a locking nut in threaded connection with the screw threads is arranged on the outer circle of the second end of the inner rotating shaft; and the end of the locking nut abuts against the end of the second limiting ring.

Owner:AECC HUNAN AVIATION POWERPLANT RES INST

End mill

ActiveUS20150251254A1Reduce feed forceLow cut speedMilling cuttersAdverse effect compensationFluteEnd mill

Described is an end mill with four straight front cutting edges arranged on a front side and a corresponding number of circumferential cutting edges that each emanate from the outer nose of the front cutting edges and are separated from each other by flutes. One of the front cutting edges passes over into a second cutting edge via a free surface intersecting line. The additional front cutting edges lying between the latter in the cutting direction are offset relative to each other by a first angular pitch of 180°, and end before the middle. So that the end mill can be used in an especially advantageous manner for incorporating dimensionally and positionally precise pilot holes or chamfering curved work piece surfaces, the first front cutting edge is offset relative to the second front cutting edge in the cutting direction by a second angular pitch ranging between 173° and 177°, preferably between 174° and 176°, wherein the first front cutting edge is offset relative to the next additional front cutting edge in the cutting direction by a third angular pitch ranging between 90° and 94°, preferably between 91° and 93°.

Owner:GUEHRING OHG

Centering device

ActiveCN111152149AGuarantee the stability of the card connectionAccurate and fast docking installationWork holdersEngineeringMechanical engineering

Owner:CHINA FIRST AUTOMOBILE

Ignition coil, spark plug, and ignition set-up including an ignition coil and spark plug

ActiveUS9194359B2Simple contactReduce overall outer diameterSparking plugsTransformersIgnition coilElectrical connection

In an ignition coil having a high-voltage terminal and a spring for electrically connecting the high-voltage terminal to a spark plug, a contact segment of the spring, which is directed towards the spark plug, has an outer circumference that is reduced in comparison with an outer circumference of further segments of the spring. The spark plug has a contact region for contacting with the spring of the ignition coil, which contact region has a recess surrounded by a closed, annular wall region for receiving the contact segment of the spring of the ignition coil.

Owner:ROBERT BOSCH GMBH

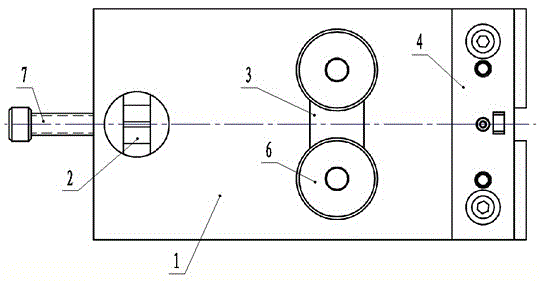

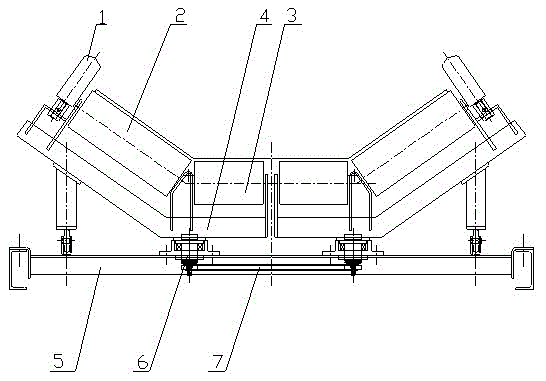

Full-automatic reversible conveying belt aligning idler

InactiveCN104418036AGood centering effectSmall turning radiusConveyorsRollersEngineeringFour-bar linkage

The invention relates to a full-automatic reversible conveying belt aligning idler. The full-automatic reversible conveying belt aligning idler comprises an upper beam (4), a lower beam (5), rotating shafts (6) and a four-connecting bar mechanism (7), the upper beam (4) and lower beam (5) are connected through the rotating shafts (6), vertical rollers (1) are arranged at the top of the upper beam (4), baffle rollers (2) are arranged at the middle, idlers (3) are arranged at the lower part, the vertical rollers (1), baffle rollers (2), idlers (3), upper beam (4) and rotating shafts (6) are symmetrically arranged in the horizontal direction in a mode of using the vertical central line of the lower beam (5) as a symmetrical axis, and the bottoms of two rotating shafts (6) are connected through the four-connecting bar mechanism (7). When the belt deviates on the idler, the full-automatic reversible conveying belt aligning idler drives the upper beam to rotate by a certain angle, and reverse rotating force is exerted to the idlers at the two sides by means of the rotating shafts so as to enable the deviated belt to return to the original position.

Owner:JIANGYIN BOFAN MACHINERY MFR

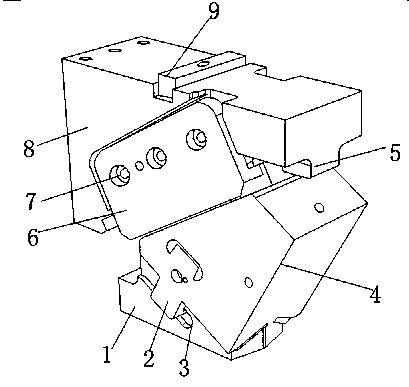

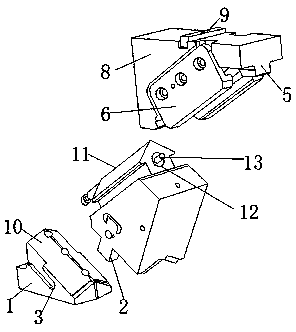

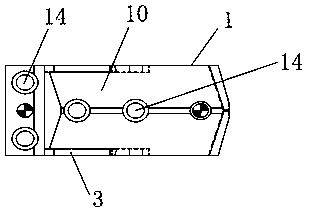

Automobile die tapered wedge device

InactiveCN108856514AImprove the centering effectExtended service lifeShaping toolsVehicle componentsEngineeringNitrogen gas

The invention discloses an automobile die tapered wedge device which comprises a tapered wedge base, a lewisson block and a sliding block base. The top end of the tapered wedge base is provided with afirst V-shaped guide convex block arranged in an inclined mode, the outer wall of the bottom end of the lewisson block is provided with a first V-shaped groove matched with the first V-shaped guide convex block, the outer walls on the two sides of the tapered wedge base are provided with first guide sliding grooves formed in an inclined mode, the two sides of the bottom end of the lewisson blockare provided with guide clamping blocks matched with the first guide sliding grooves in specification, the two guide clamping blocks are movably connected with the inner walls of the first guide sliding grooves, and the top end of the lewisson block is provided with a second V-shaped guide convex block arranged in an inclined mode. The centering guiding effect of the tapered wedge device during sliding is improved, bad friction caused by component dislocation is reduced, the service life of the tapered wedge device is prolonged, the application range of the device is widened, device reset is better facilitated through a nitrogen spring arranged in a matched mode, replacement and maintenance are convenient, the maintenance cost is reduced, and the using cost is saved.

Owner:青岛宇信机电科技有限公司

Rapid sealing assembly with drawstring buckling for star soil coring soft bag

The invention relates to a rapid sealing assembly with drawstring buckling for a star soil coring soft bag, and belongs to the field of star catalogue drilling and sampling mechanisms. The rapid sealing assembly with drawstring buckling for the star soil coring soft bag solves the problem that when sampling operation is carried out on an existing moon exploration project, a sealing journey of a sampling soft bag in the sealing process is long and affects the star soil collection quantity. A second sealing opening is located between a first sealing opening and an opening end of the coring softbag, wherein the first sealing opening comprises a first inhaul cable and a second inhaul cable, the two inhaul cables are used as wraps and symmetrically weaved on the coring soft bag, and the two ends of each inhaul cable are used as extending segments extending out of the coring soft bag. One extending segment of the second inhaul cable is wrapped with one extending segment of the first inhaulcable and buckling is performed, and the other extending segment of the first inhaul cable is wrapped with the other extending segment of the second inhaul cable and buckling is performed. First fracturing areas are arranged on the inhaul cables, the end part of the other extending segment of the first inhaul cable and the end part of the extending segment of the second inhaul cable are fixedly connected with limiting rings, and the first sealing opening and the second sealing opening have same structures.

Owner:HARBIN INST OF TECH

Twist drill for machining holes of laminated welded steel

ActiveCN110842259ANo change in sharpnessGood reassuring effectTransportation and packagingTwist drillsChiselStructural engineering

The invention discloses a twist drill for machining holes of laminated welded steel. The twist drill for machining holes of the laminated welded steel includes a cutting part and a shank part. The cutting part includes a drill tip and a secondary cutting part, and the drill tip is provided with two main cutting edges and a chisel edge connecting the two main cutting edges. The secondary cutting part is provided with two chip discharging grooves and two first cutting edge belts, and the first cutting edge belts and the chip discharging grooves intersect to form a secondary cutting edge. The main cutting edges are provided with negative chamfers, and the negative chamfers do not pass the intersections of the main cutting edges and the chisel edge. The length of the chisel edge is L5, whereinthe L5 is larger than or equal to 0.017D and less than or equal to 0.03D, and D is the diameter of the cutting part. According to the twist drill for hole machining of the laminated welded steel, thelength of the chisel edge is only one third of that of a conventional chisel edge, the length of the chisel edge of the drill tip is small, the centering capacity during drilling of the laminated welded steel is increased, the twist drill for hole machining of the laminated welded steel is suitable for drilling machining of steel with varying hardness among different materials, the problem of drilling deviation in the drilling process is reduced, the negative chamfers are arranged on the main cutting edge, no negative chamfer is arranged on the entire chisel edge, and the sharpness of the chisel edge is not changed while the strength of the main cutting edge is increased, so that the centering performance of the chisel edge is better.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

General-purpose multiple-cutting edge drill

InactiveUS9545676B2Good centering effectReduce resistanceWood turning toolsTransportation and packagingGeneral purposeChisel

A general-purpose multiple-cutting edge drill includes: a drill point (1); a drill body (2); margins (3) located on an outer wall of the drill body (2); two lips, wherein, if viewed from an axial direction, from out to inside, each of the two lips successively includes an outer cutting edge (11), an arc cutting edge (12) and an inner cutting edge (13); a chisel edge (14); outer peaks (15) formed by intersection of the outer cutting edges (11) and the arc cutting edges (12); a center peak (16) formed by intersection of two inner flank surfaces and two split surfaces. Moreover, an included angle between the inner cutting edges (13) ranges from 108° to 128°, an included angle between the outer cutting edge (11) ranges from 130° to 140°, and an included angle between the inner cutting edge (13) and outer cutting edge (11) ranges from 28° to 40°.

Owner:NINGBO HUAREN TOLLS +1

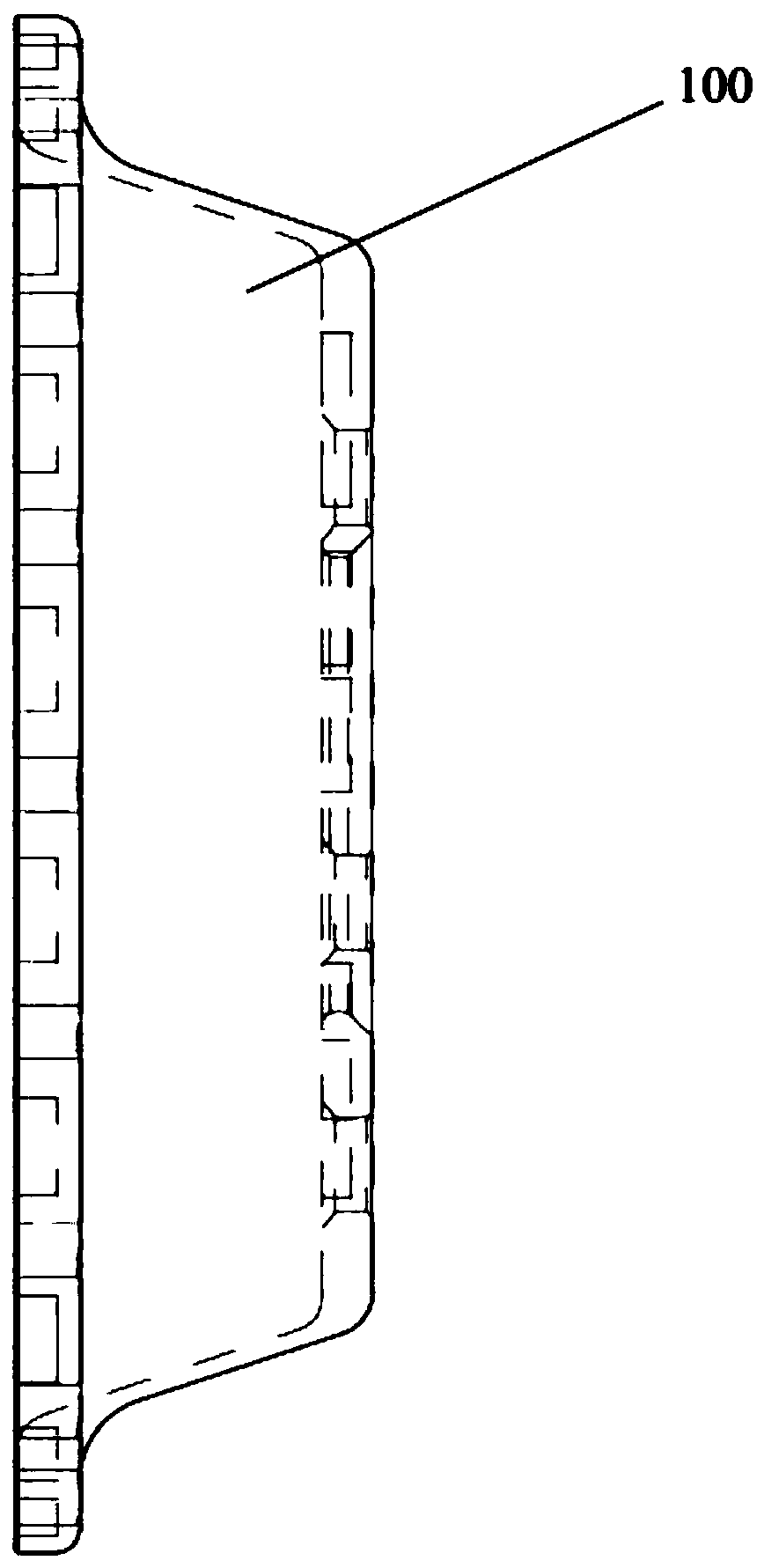

Automatic tread feeding device

PendingCN108790230AGood centering effectThe test result is accurateTyresPlastic recyclingMechanical engineeringTread

The invention provides an automatic tread feeding device. The feeding device comprises a rack and further comprises an overturning device, a conveying device, a centering device, a length measuring device, an anti-drifting device and an attaching device which are arranged on the rack; and the rack is provided with a first support and a second support in parallel in the length extending direction of the rack.

Owner:HANGZHOU CHAOYANG RUBBER

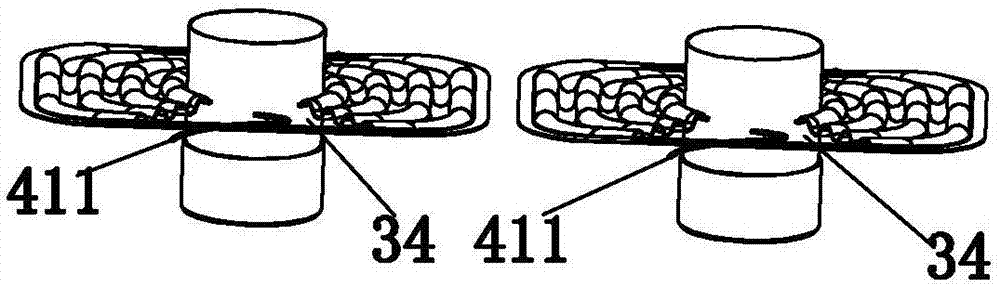

Disconnection-proof loudspeaker diaphragm system

ActiveCN107484084AImprove sound qualityImprove connection strengthDiaphragm constructionDiaphragm mounting/tensioningBobbinNoise

The invention discloses a disconnection-proof loudspeaker diaphragm system. The disconnection-proof loudspeaker diaphragm system comprises a voice coil bobbin, a centering support piece, a diaphragm and a dustproof cap; the voice coil bobbin is cooperated with and adhered to the centering hole of the centering support piece; the diaphragm is arranged at the outside of the voice coil bobbin in a sleeving manner and is adhered to the voice coil bobbin and the centering support piece; the dustproof cap is arranged at the diaphragm; a first convex ring and a second convex ring are arranged at the periphery of the voice coil bobbin; a first annular groove is formed in the inner wall of the centering hole of the centering support piece; a second annular groove is formed in the lower end of the diaphragm; the first annular groove of the centering support piece is cooperated with and adhered to the first convex ring of the voice coil bobbin; and the second annular groove of the diaphragm is cooperated with and adhered to the second convex ring of the voice coil bobbin. The disconnection-proof loudspeaker diaphragm system is reasonable in structure, high in connection strength, strong in centering effect and good in stability, reduces noises efficiently and is good for improving the tone quality of the loudspeaker.

Owner:JIAXING JINLIDA ELECTRON

Automatic reaming and counterboring cutter applicable to weakly rigid equipment

InactiveCN111360301AImprove hole finishAvoid contactTransportation and packagingTrepanning drillsEngineeringStructural engineering

The invention provides an automatic reaming and counterboring cutter applicable to weakly rigid equipment. The cutter comprises a cutter body used for performing machining and a cutter clamping handleportion. The cutter body is provided with a drilling portion and a counterboring portion from top to bottom in sequence. The drilling portion, the counterboring portion and the cutter clamping handleportion are integrally formed. The drilling portion comprises a drilling tip and a cutting edge. A spiral groove and a counterboring edge are formed on the counterboring portion. A transition filletis arranged between the spiral groove and the counterboring edge. The cutting edge comprises a ridge, a transverse edge body and a main cutting edge body. The drilling tip reams a product, the counterboring edge performs counterboring on the reamed product, and the central axes of the drilling tip and the counterboring edge are located on the same straight line. The design of the cutter provided by the invention is oriented to the weakly rigid equipment, the centering ability is improved, the pore diameter precision is improved, vibration during drilling is reduced, the inverted cone design ofthe cutter effectively prevents contact between the cutter and a pore wall, and the pore wall degree of finish is increased.

Owner:SHANGHAI TOPNC NUMERICAL CONTROL TECH CO LTD

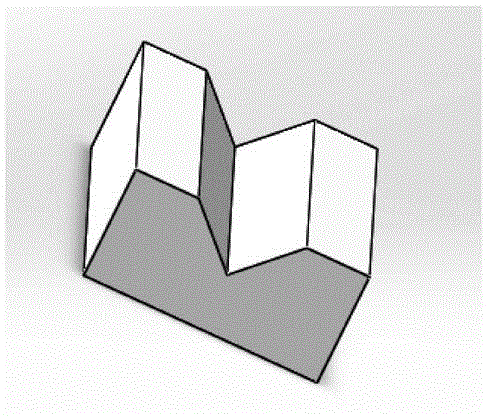

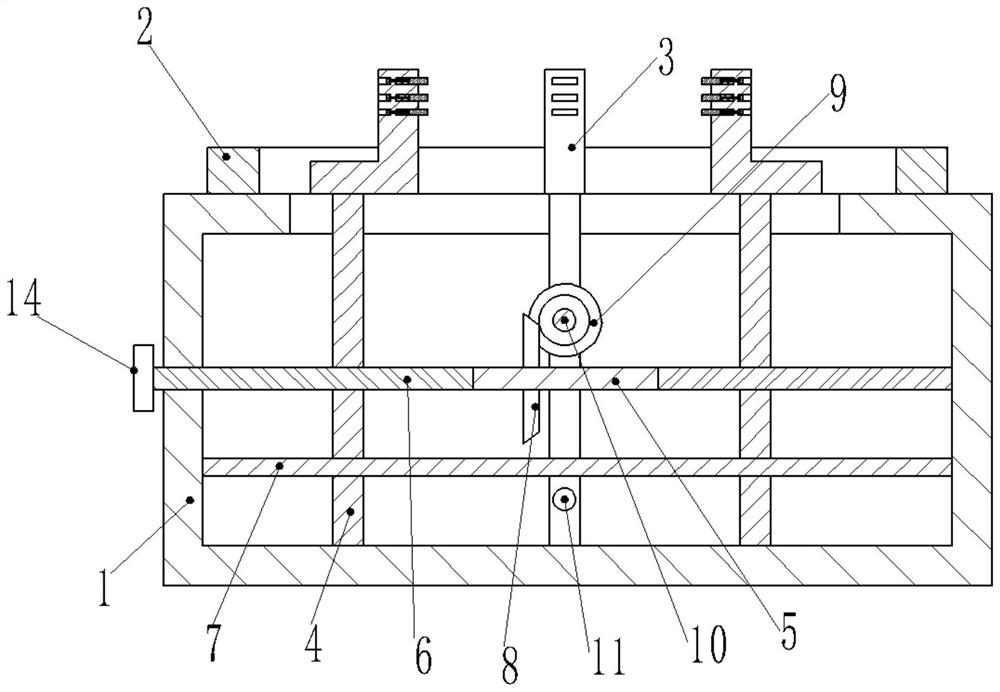

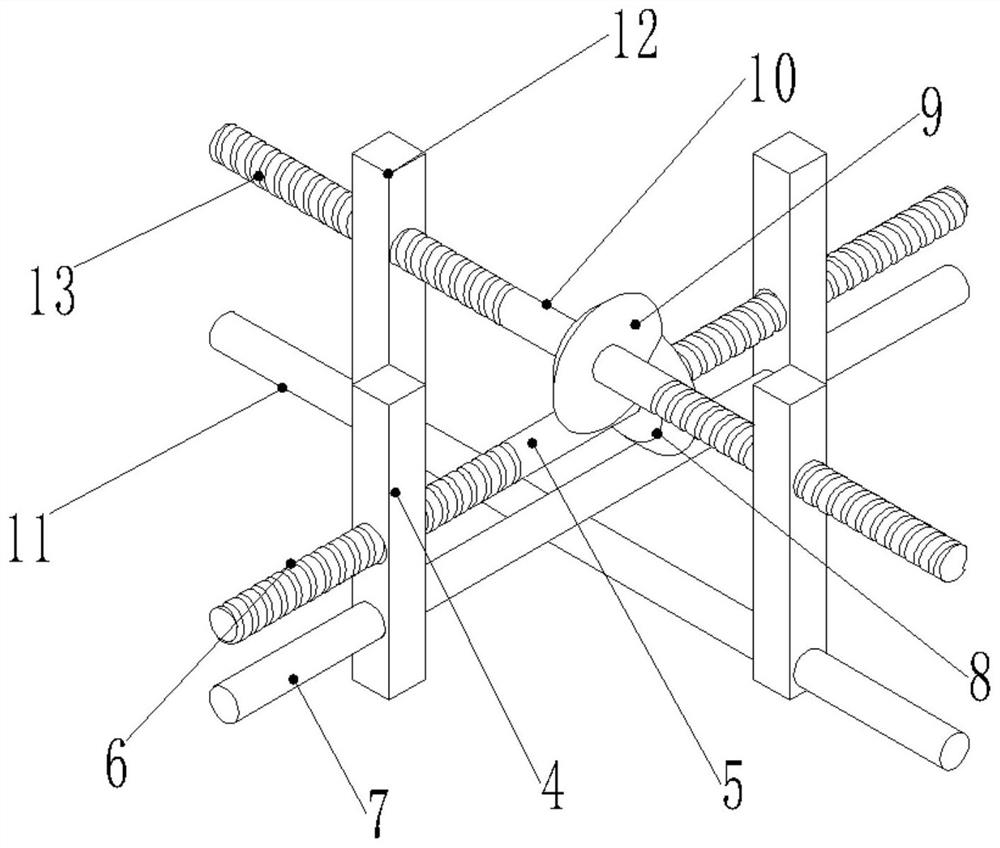

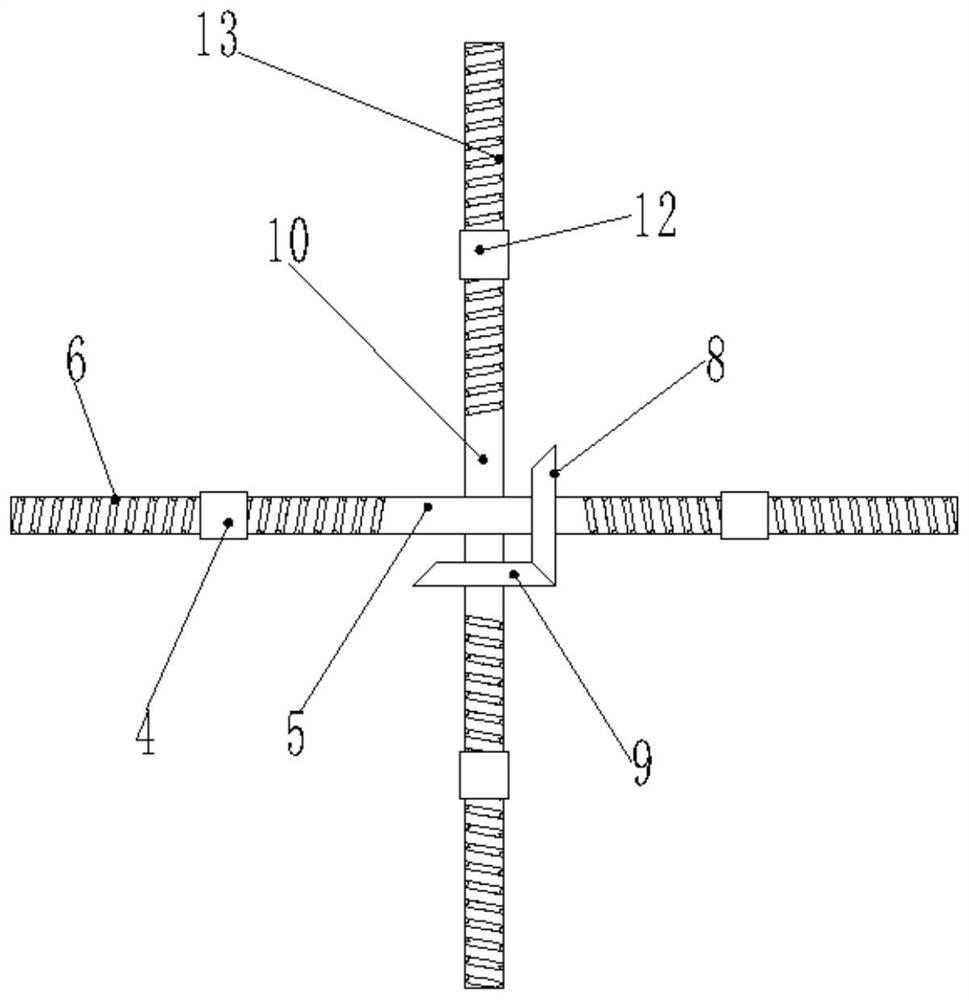

Stable clamping and centering device for spare and accessory part machining

The invention discloses a stable clamping and centering device for spare and accessory part machining. The stable clamping and centering device comprises a control cabinet body and a clamping platform; the clamping platform comprises a platform body and a sliding chute; a clamping block is connected into the sliding chute in a sliding mode; a clamping mechanism is arranged in the control cabinet body; the clamping mechanism comprises a transverse clamping structure and a longitudinal clamping structure; the transverse clamping structure comprises transverse clamping plates, a transverse driving shaft, transverse lead screws and a transverse sliding rod; two sets of transverse lead screws are arranged, and the rotating directions of threads on the two sets of transverse lead screws are opposite; the transverse lead screws are rotationally connected with the control cabinet body; two sets of transverse clamping plates are arranged and are in threaded connection with the two sets of transverse lead screws correspondingly; the transverse sliding rod is in sliding connection with the transverse clamping plates; a lower bevel gear is fixedly connected to the transverse driving shaft; anupper bevel gear is arranged on the longitudinal clamping structure; and the lower bevel gear is in meshed transmission connection with the upper bevel gear. According to the stable clamping and centering device for spare and accessory part machining, a good centering effect is achieved after spare and accessory parts are clamped, errors caused by centering clamping of the machined spare and accessory parts are small, and the machining precision of the spare and accessory parts is improved.

Owner:ZHUZHOU HUAXIN PRECISION IND

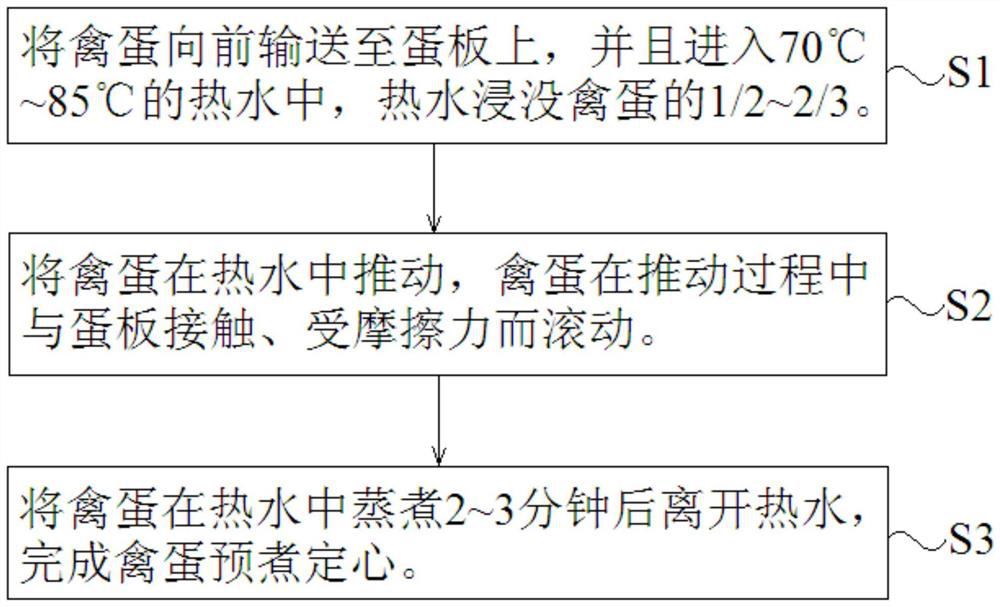

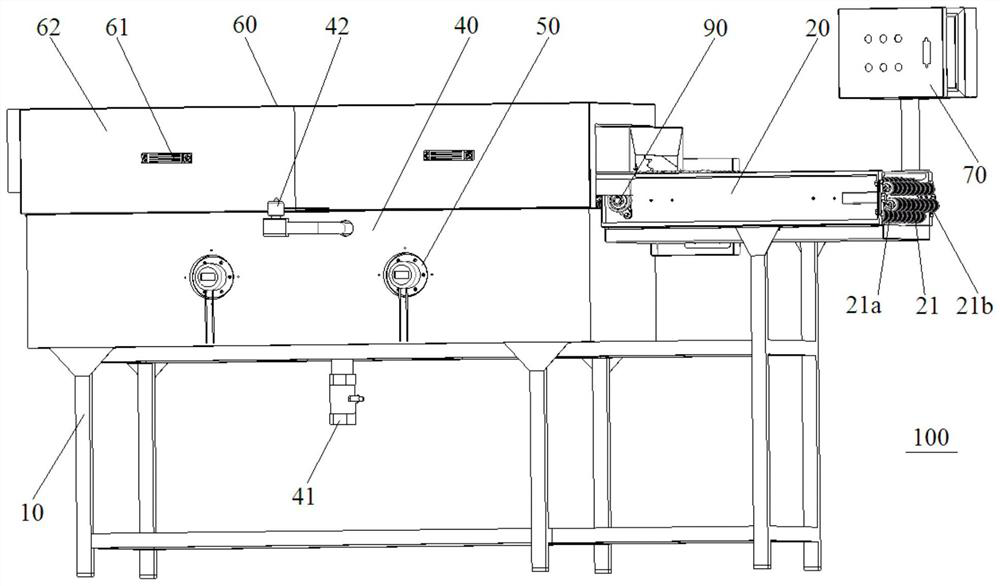

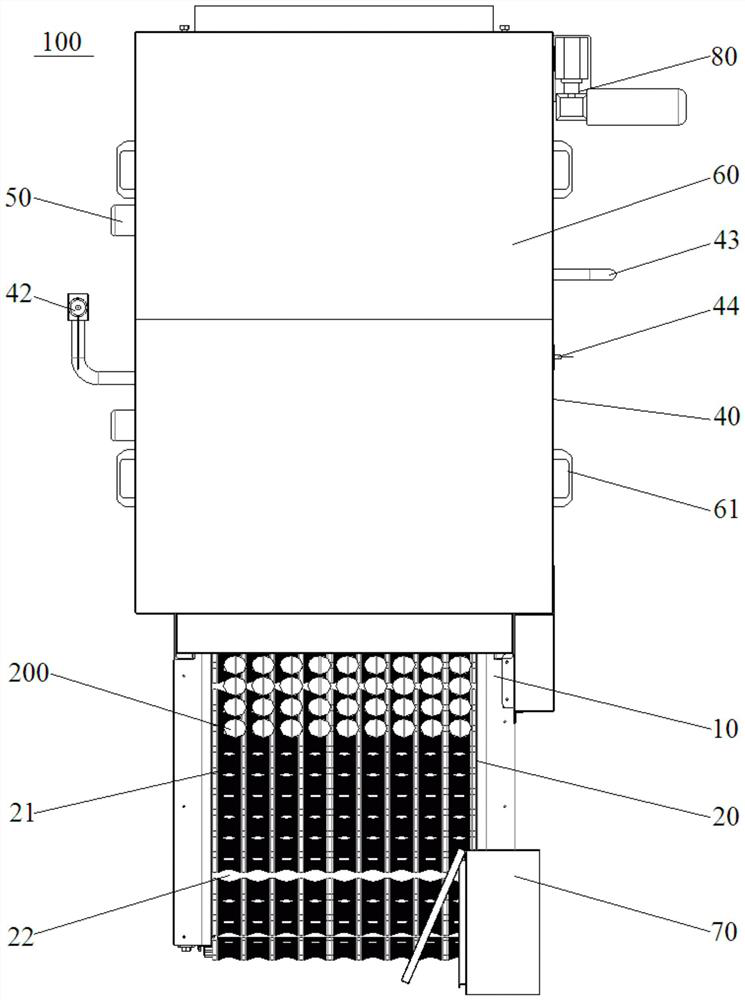

Poultry egg preboiling centering method and poultry egg preboiling centering machine

PendingCN111728155AImprove heating efficiencyGood centering effectCharge manipulationConveyor partsYolkAnimal science

The invention discloses a poultry egg preboiling centering method and a poultry egg preboiling centering machine. The method comprises the following steps of forwards conveying poultry eggs onto an egg plate; enabling the poultry eggs to enter hot water being 70 to 85 DEG C; soaking 1 / 2 to 2 / 3 of the poultry eggs by the hot water; pushing the poultry eggs in the hot water; enabling the poultry eggs to be in contact with the egg plate in the pushing process and to roll through receiving the friction force; steaming and boiling the poultry eggs in the hot water for 2 to 3 min; then, enabling thepoultry eggs to leave away from the hot water; and completing the poultry egg preboiling centering. The poultry egg preboiling centering machine comprises a machine frame, upper egg conveying equipment, preboiling centering conveying equipment and a water tank, wherein the upper egg conveying equipment, the preboiling centering conveying equipment and the water tank are arranged on the machine frame. The poultry egg preboiling centering method and the poultry egg preboiling centering machine provided by the invention have the advantages that the hot water is used for directly steaming and boiling the poultry eggs; the hot water is directly in contact with the poultry eggs and always covers the poultry eggs, so that the heating efficiency is high; and the water consumption is very low. Inaddition, the poultry eggs continuously roll and move in the preboiling process; the yolks can be enabled to be always in the centers of the poultry eggs; and the centering effect is good.

Owner:振野(惠州)实业有限公司

Sound production device

PendingCN107197408AImprove low frequency responseGood reassuring effectNon-planar diaphragms/conesEngineeringBobbin

The invention discloses a sound production device which comprises a housing, a vibrating diaphragm connected and fixed with the housing and a voice coil unit combined with the vibrating diaphragm. The voice coil unit comprises a voice coil and a skeleton supporting the voice coil; the voice coil unit is connected with a centring disk; a signal access terminal electrically connected with an outgoing line of the voice coil is arranged on the housing; an abdicating portion formed by cutting is formed on the centring disk; and the outgoing line of the voice coil is led out by the abdicating portion and is electrically connected with the signal access terminal. The sound production device disclosed by the invention is excellent in low-frequency response, and cannot generate noise when carrying out high-power working.

Owner:潍坊歌尔丹拿电子科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com