Poultry egg preboiling centering method and poultry egg preboiling centering machine

A technology of centering machine and poultry eggs, which is applied in the field of poultry and egg processing, can solve the problems that have not been popularized and applied, cannot realize centering, heat solidification, etc., and achieve the effect of good centering effect, high centering efficiency and high heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

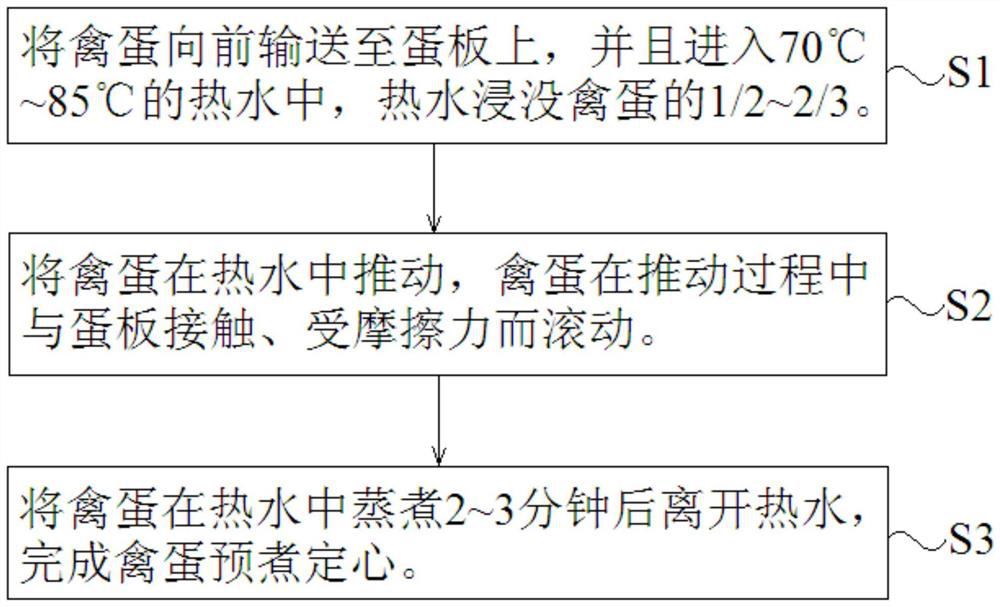

[0040] An embodiment of the present invention provides a precooked centering method for poultry eggs, see figure 1 , including the following steps:

[0041]S1. Transport the poultry eggs forward to the egg plate, and enter into hot water at 70°C to 85°C. The temperature of the hot water is preferably 75°C to 80°C, and the hot water immerses 1 / 2 to 2 / 3 of the poultry eggs.

[0042] This step S1 is the egg loading process. The poultry eggs are pre-cooked and centered using batch operations. Multiple poultry eggs are conveyed forward in sequence, and the eggs are moved to the egg plate in turn. The egg plate is soaked in hot water, and the egg plate is set. If the immersion depth is lower, it can control 1 / 2 to 2 / 3 of the poultry eggs immersed in hot water. Eggs are normally placed horizontally, that is, the long axis is placed horizontally, so hot water is immersed in 1 / 2 to 2 / 3 of the short axis of the egg, such as 50%, 55%, 60% or 65% of the volume of the egg Immerse in hot ...

Embodiment 2

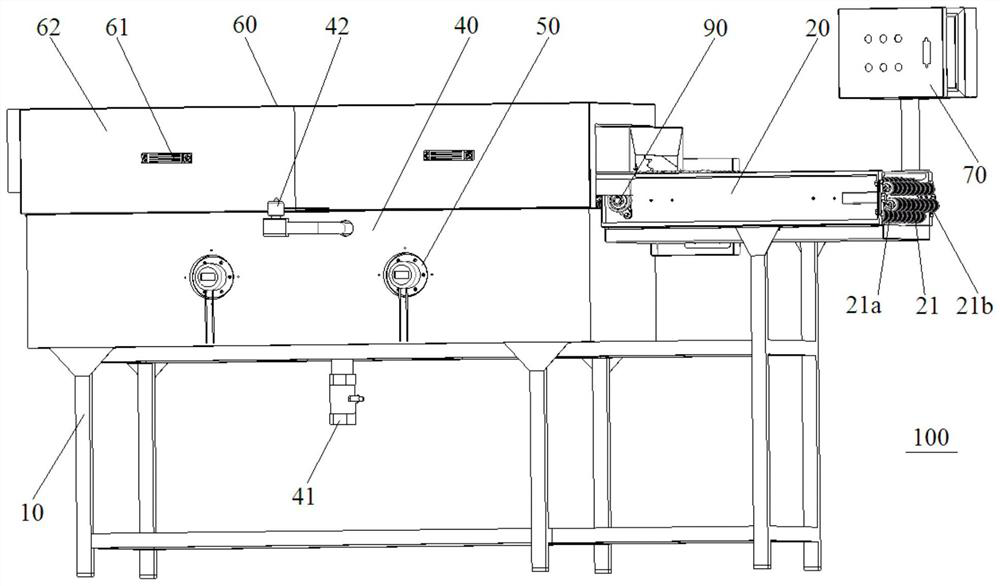

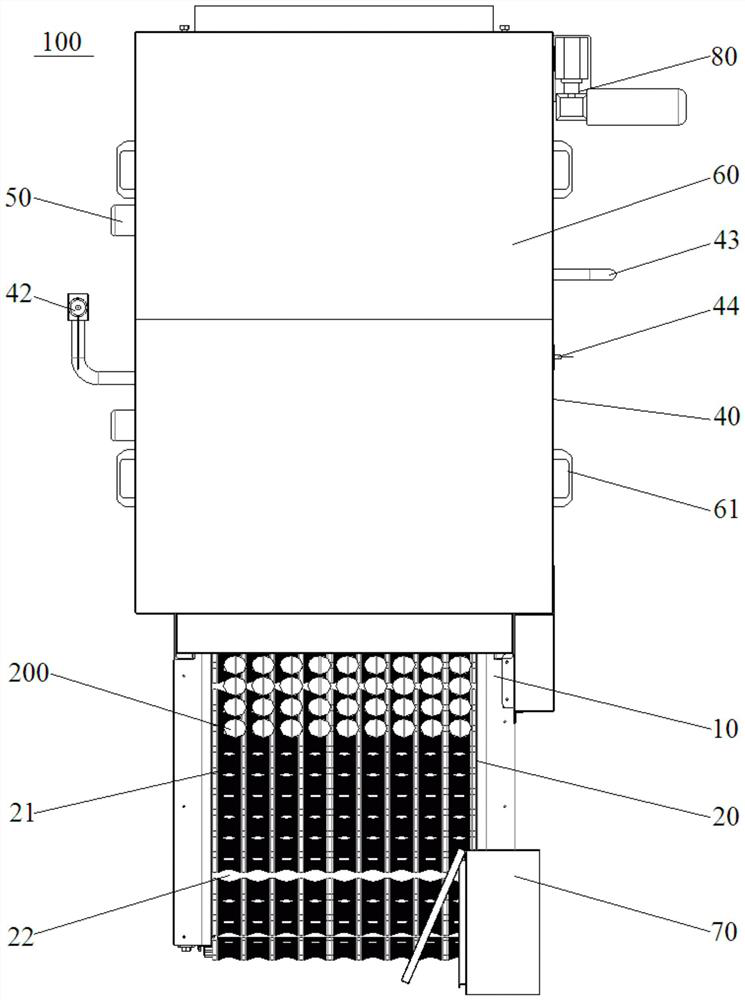

[0048] Based on the same inventive concept, an embodiment of the present invention provides a poultry egg precooking and centering machine, which is used to implement the poultry egg precooking and centering method in the above-mentioned embodiment 1. see figure 2 The poultry egg precooking centering machine 100 comprises a frame 10, an egg conveying device 20, a precooking centering conveying device 30 and a water tank 40, and the egg conveying device 20, the precooking centering conveying device 30 and the water tank 40 are all installed in on the frame 10, and the output end of the egg conveying device 20 is docked with the input end of the precooked centering conveying device 30.

[0049] Below in conjunction with a typical embodiment, the structure of each component of poultry egg precooking centering machine 100 of the present invention is described in detail:

[0050] see Figure 2 to Figure 4 , the frame 10 is the installation basis of the whole poultry and egg prec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com