Automatic reaming and counterboring cutter applicable to weakly rigid equipment

An automatic manufacturing and weak rigidity technology, applied in the direction of manufacturing tools, metal processing equipment, drilling/drilling equipment, etc., can solve the problems that cannot meet the needs of automatic assembly, improve the finish of the hole, improve the finish of the hole wall, reduce the The effect of small vibrations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

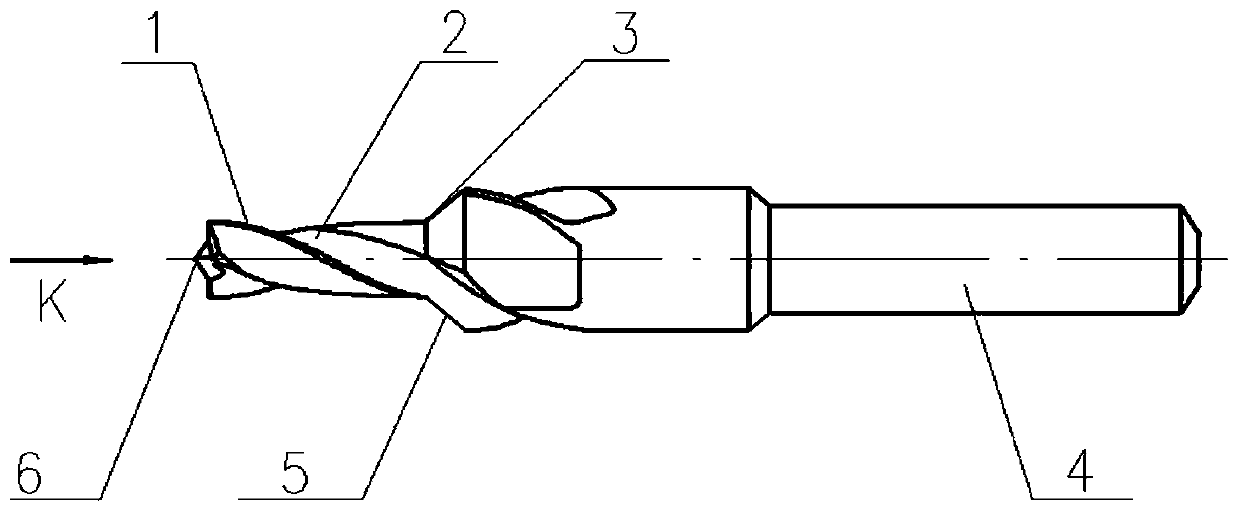

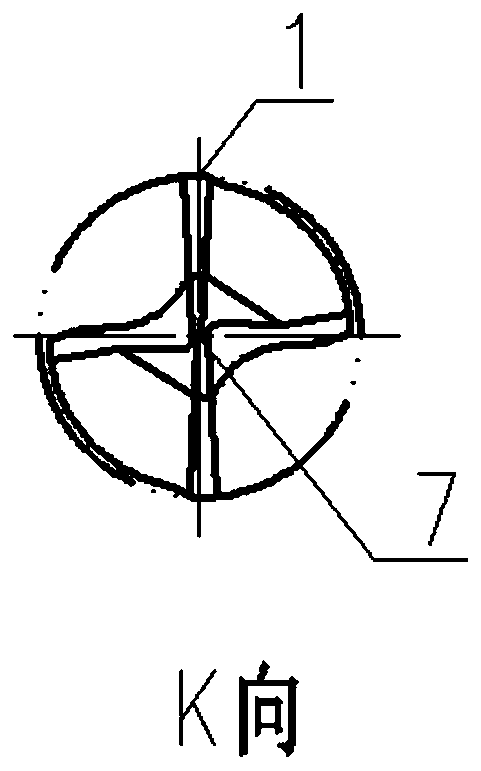

[0033] As a preferred embodiment of the present invention, the helical grooves are arranged at variable helix angles, and the interior of the helical grooves is finely polished.

[0034] As a preferred embodiment of the present invention, the helix angle of the variable helix is 30°-40°.

[0035] As a preferred embodiment of the present invention, the countersinking edge is a linear countersinking edge, so that the angle of the countersinking is more precise, the accuracy of the cooperation with the fastener is higher, and the assembly life of the aircraft parts is improved.

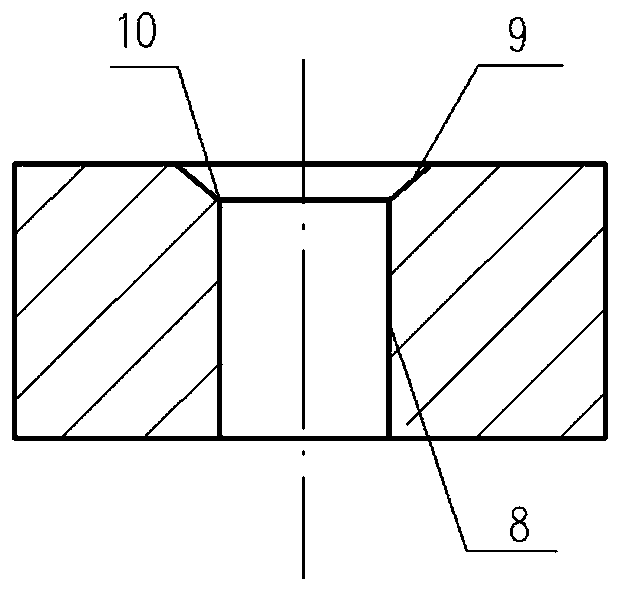

[0036] As a preferred embodiment of the present invention, the tool clamping handle is a high-precision clamping handle, and the tolerance of the high-precision clamping handle is h6, which can be matched with any type of tool holder.

[0037] As a preferred embodiment of the present invention, the tool body is designed as an inverted cone, which cuts briskly, reduces the friction between the tool and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com