Pore burr removing device

A technology for fixing holes and racks, applied in the field of mechanical processing equipment, can solve the problems of expensive equipment, low cost, high processing cost, etc., and achieve the effect of simple structure, high efficiency, and improved hole finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

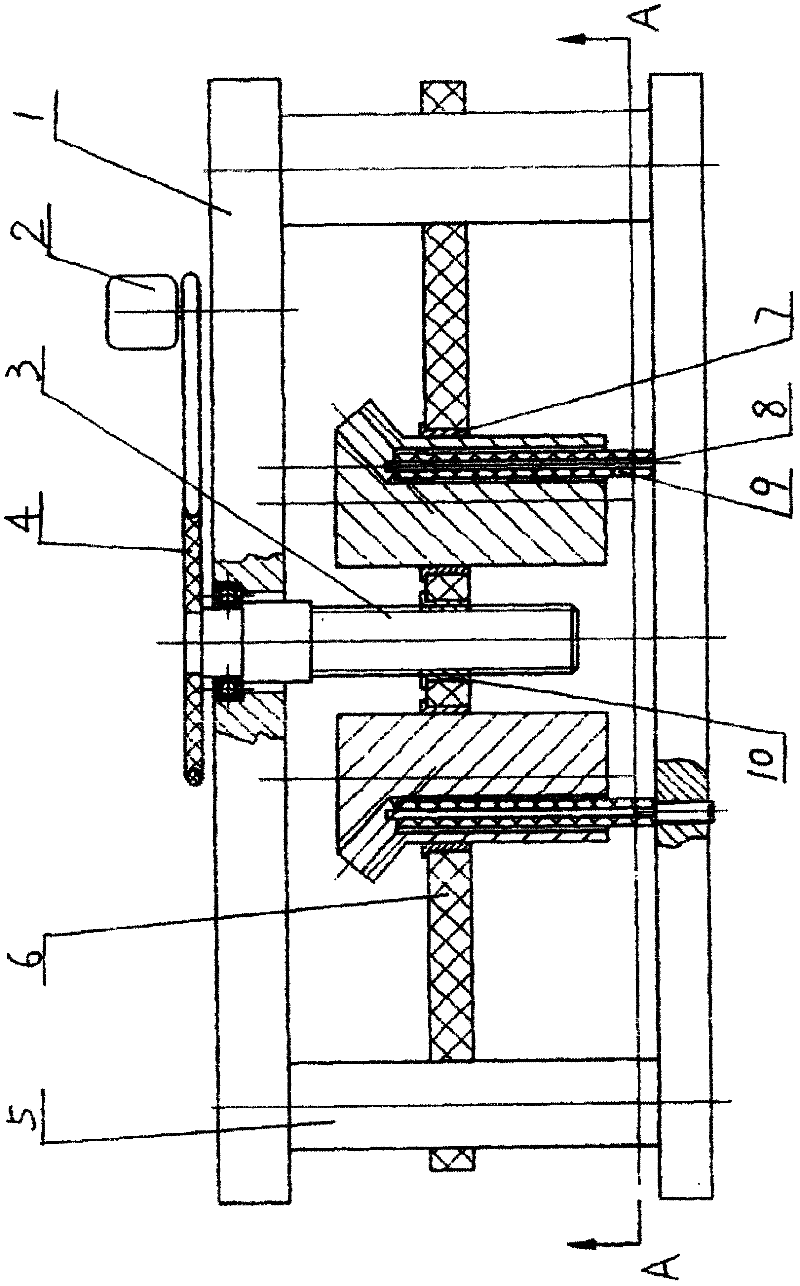

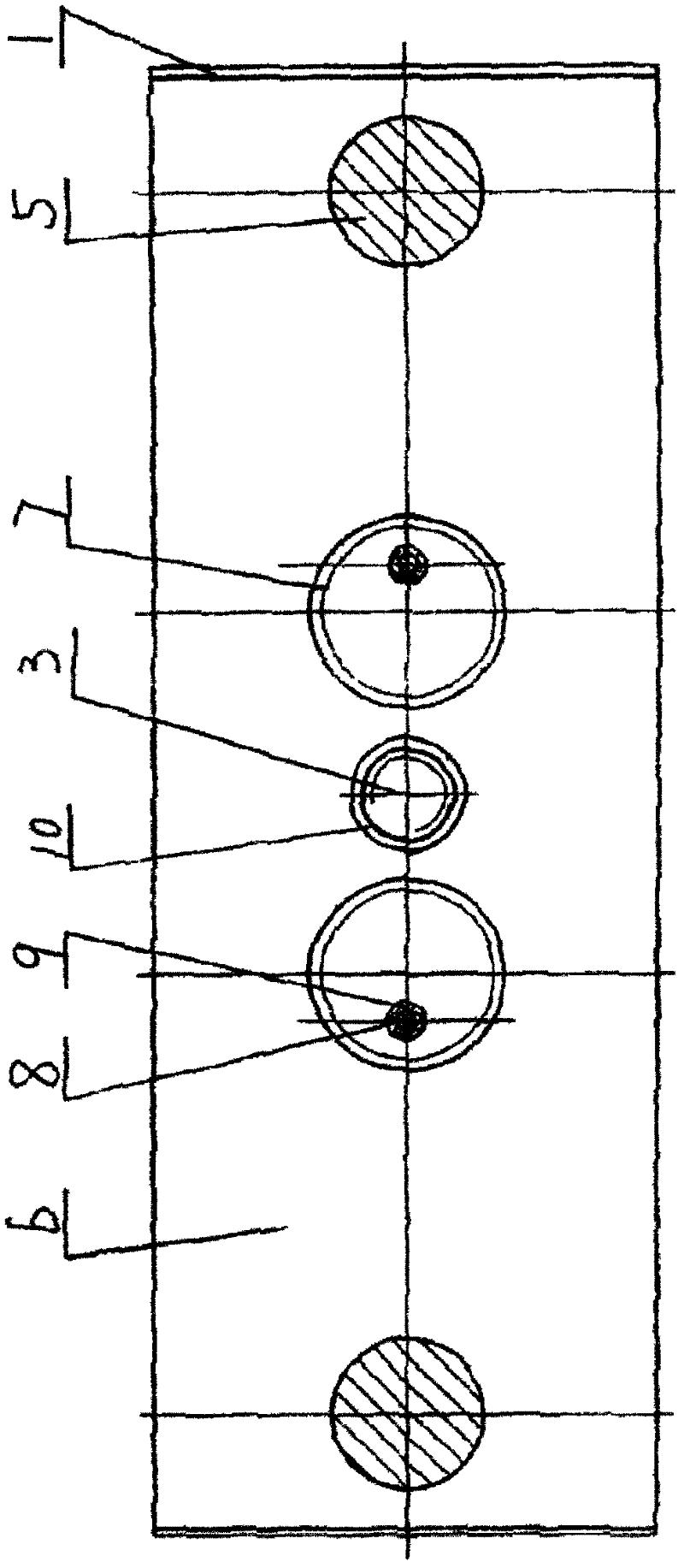

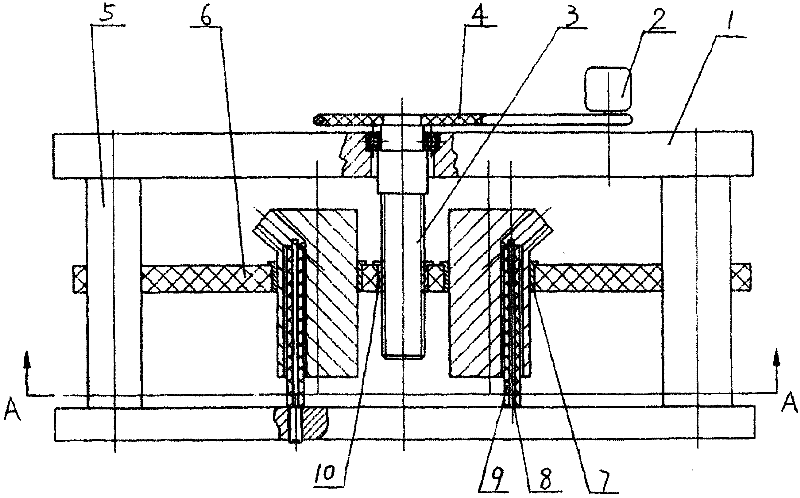

[0009] reference figure 1 , figure 2 . A device for removing burrs in holes. A motor 2 is installed on the frame 1. One end of the screw 3 is installed on the upper side of the frame 1 through a bearing and a bearing seat; the motor 2 is connected to the pulley 4 on one end of the screw 3 through a belt; The frame 1 is provided with two guide posts 5, the guide post 5 is covered with an insulating support plate 6; the other end of the lead screw 3 passes through the insulating support plate 6, and is connected to the insulating support plate 6 through a nut 10; on the insulating support plate 6 One or more workpiece fixing holes are provided, and a metal conductive copper sleeve 7 is inlaid in the fixing holes; an electrode 8 is arranged on the lower frame 1 corresponding to the fixing hole, and the part below the tip of the electrode 8 is covered with an insulating material 9. In this embodiment, two workpiece fixing holes with copper sleeves 7 are provided on the insulating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com